A wrench is an essential hand tool designed to provide grip and mechanical advantage to apply torque for turning or securing nuts, bolts, and other fasteners. There are many different types of wrenches available on the market today, such as Open-End Wrenches, Box-End Wrenches, or Ratcheting Wrenches, which often leaves us unsure of which wrench is the most suitable for our needs.

When selecting a wrench, the most important factors are the specific application, the size and type of fastener, accessibility to the working area, and the torque requirements. Regardless of the wrench type, a good wrench should offer proper fit, durable construction, and ergonomic design for efficient and comfortable use. Understanding these common points will ensure you select the right wrench suited for your tasks.

This article covers the most comprehensive types of wrenches currently availableon the market, including even some very rare wrench varieties. We will alsoexplain the design highlights, application ranges, and basic principles of eachwrench. Please continue reading,

Thin/Ultra-Thin Wrench

Design: Ultra-thin profile design, with a thickness of just 2.1–4.6 mm, approximately half the thickness of a standard wrench.

Ideal for: Fastener operations in narrow gaps and confined spaces where standard wrenches cannot be used.

The Thin/Ultra-Thin Wrench features an extremely slim profile design, specifically developed to address the issue of narrow spaces inaccessible to standard wrenches. This Thin/Ultra-Thin Wrench is only half the thickness of a standard wrench but maintains sufficient strength to handle most fastening tasks. Its 15-degree offset design allows users to flip the wrench to access hard-to-reach spaces and select the optimal working angle.

The true value of the thin wrench lies in its ability to access fasteners that would otherwise require extensive disassembly, thereby saving significant time and labor. In modern automotive maintenance, engine compartments are becoming increasingly compact, making thin wrenches an essential tool for specialized tasks such as brake line work, stabilizer bar end connections, and control arm end adjustments. Despite being half the thickness, the high-quality chromium-vanadium steel material and advanced heat treatment process ensure these wrenches can withstand medium to high torque applications, with engineering standards exceeding ASME standards by 30%.

Adjustable Wrench

Design: The open end features a worm gear adjustment mechanism, allowing the opening size to be adjusted by turning a screw.

Best suited for: General tightening and loosening of fasteners of various sizes.

Adjustable wrenches or crescent wrenches are highly favored by DIY enthusiasts among various types of wrenches due to their versatility. These adjustable wrenches have an open end that can be adjusted in size by simply turning the screw located at the rear of the jaw. This allows the Adjustable Wrench to accommodate various sizes of hardware and fasteners without needing to find an open-end wrench compatible with the fastener.

The gear mechanism of the Crescent Wrench takes up space, so caution is advised when using it in narrow spaces. This wrench is best suited as a general-purpose tool and backup tool in case a suitable fixed-size wrench is unavailable.

Open-End Wrench

Design: Double-ended U-shaped opening design with different opening sizes at each end

Best suited for: Hard-to-reach nuts and bolts

An open-end wrench is a double-ended wrench with a U-shaped opening at each end, with slightly different opening sizes. The flat jaws grip both sides of the fastener, allowing you to work in areas where closed-end tools cannot fit. Each end is designed to fit a specific size of nut or bolt, so mechanics require a complete set with both SAE and metric measurements.

The Open-end wrench’s long neck allows one open end to slide into narrow gaps to access nuts and bolts that may be difficult to loosen or tighten. Due to its versatile design, standard toolkits typically include multiple sizes of open-end wrenches.

Box-End Wrench

Design: Both ends are closed rings with a 6-point or 12-point grip structure inside.

Best suited for: Tightening or loosening hexagonal or square nuts and bolts.

The box wrench has two closed ends of slightly different sizes, so each end can be used to loosen or tighten fasteners of different sizes. Users simply slide the end of the socket wrench over the nut or bolt head and rotate in the desired direction to apply force.

Due to the closed-end design, socket wrenches grip fasteners more securely than open-end wrenches, preventing slippage or damage to the hardware. Higher-quality models may feature a slight offset design, allowing the head to grip recessed nuts more effectively.

Combination Wrench

Design: One end is an open U-shape, the other end is a closed flower shape, same size

Best suited for: General hardware, tightening and loosening tasks

Instead of choosing between a star wrench and an open-end wrench, users can opt for a combination wrench with one open end and one closed star end. The open crescent-shaped end allows for quicker repositioning when loosening fasteners, while the closed star end provides better grip when tightening stubborn nuts and bolts.

The combination wrench combines the versatility of an open-end wrench, allowing it to fit into narrow spaces, with the strength of a socket wrench. You can use the closed end of the combination wrench to loosen difficult nuts and then remove them with the open end, making your task simple and efficient.

Stubby Wrench

Design: Compact design with a shorter handle length, maintaining the standard wrench head functionality

Best suited for: Fastening tasks in narrow spaces

Short-handle wrenches are a general term for all types of short wrenches. Short-handle wrenches feature a shorter handle, designed for use in narrow spaces. The compact design is ideal for tight engine compartments and other areas where standard-length wrenches cannot fit. Short-handle designs include combination, ratchet, box-end, and open-end wrench styles.

These short wrenches offer the same functionality as full-size wrenches but sacrifice leverage for accessibility. The shorter length allows mechanics to turn fasteners in the tightest spaces, such as between engine components or inside mechanical housings.

What is a Screwdriver? Complete Guide to Types, Uses & Selection

Socket Wrench

Design: Handle with interchangeable cylindrical sockets that fit over fasteners

Best suited for: Efficient tightening and loosening of fasteners of various sizes

Socket wrenches are available in 1/4, 3/8, and 1/2-inch drive sizes to accommodate different torque requirements. A complete socket set can be adapted to each drive size. Each socket size grips six or twelve points around the nut and bolt. Pipe wrenches grip and rotate circular threaded pipes and pipe fittings with serrated, offset jaws.

Sockets can be rotated vertically or horizontally, depending on the handle’s orientation. Long handles provide leverage for stubborn pipes, and the jaws automatically tighten during use. The serrations leave marks on the pipe surface, so this wrench is primarily used for rough pipe work rather than precision fittings.

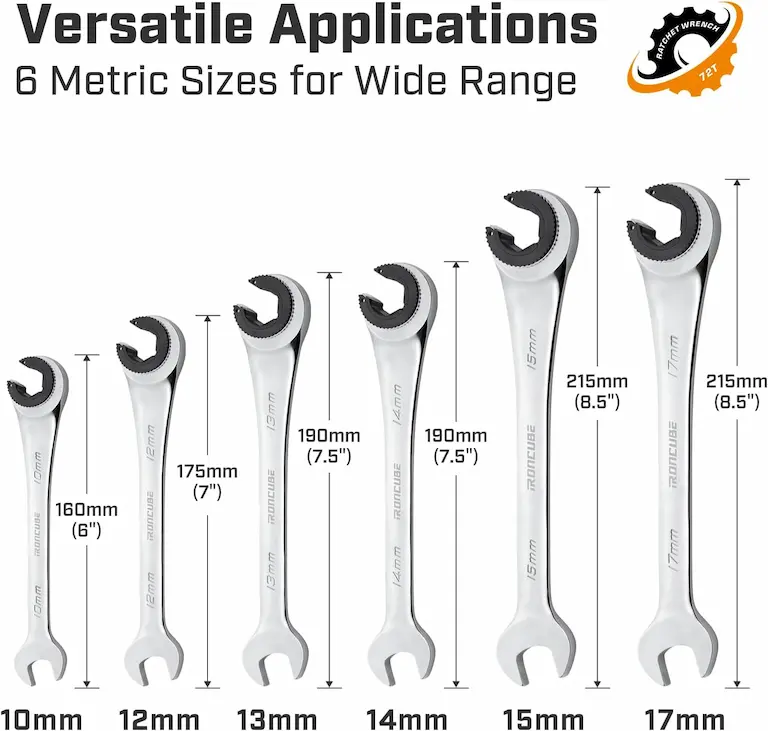

Ratcheting Wrench

Design: Built-in ratchet mechanism allows for one-way rotation without repositioning the wrench.

Best suited for: Quick and efficient tightening and loosening in compact areas.

Ratchet wrenches are similar to combination wrenches, but have a ratchet mechanism built into one end. They can loosen nuts or bolts without repositioning or removing the wrench. If you need to work in compact areas, a ratchet wrench is the ideal choice.

The internal mechanism of a ratchet wrench allows users to tighten or loosen fasteners without removing the tool from the fastener. This is particularly useful in space-constrained situations, as traditional wrenches require complete removal and repositioning to continue turning. The ratchet function significantly enhances work efficiency and speed.

Torque Wrench

Design: Built-in torque measurement and limitation mechanism, allowing for the setting of specific tightening force values

Best suited for: Applications requiring precise torque control, such as automotive and mechanical repairs

A torque wrench adjusts and applies torque to nuts and bolts. This tool is used for replacing wheels in mechanical and automotive applications. There are various types of torque wrenches. Ensure compliance with each vehicle’s torque specifications, as excessive torque can damage threads.

Tightening bolts requires some skill. Doing it incorrectly could damage your vehicle. This is where a torque wrench comes in handy. This precision tool ensures fasteners are tightened to the exact force value specified by the manufacturer, preventing damage from over-tightening or loosening from under-tightening.

Impact Wrench

Design: Electric or pneumatic drive, internal hammering mechanism provides high torque output

Best suited for: Fast, powerful pneumatic tightening and loosening operations

One of the more expensive types of wrenches is the impact wrench. This type of wrench resembles a drill with a bulky body and trigger used to drive the wrench head. However, impact wrenches do not use drill bits but instead use various sizes of sockets depending on the size of the target fastener.

Impact wrenches are connected to an air compressor to drive the socket, allowing it to apply high levels of force at high speeds for tightening or loosening. Impact wrenches use compressed air or electricity to provide high torque and rapid hammering, making them ideal for heavy-duty tasks such as removing and installing tire nuts. This tool is perfect for tasks requiring significant torque and power.

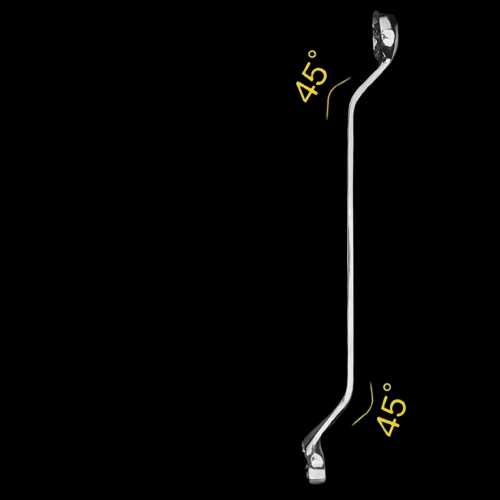

Offset Wrench

Design: The head is bent at a certain angle relative to the handle, providing clearance space.

Best suited for: Approaching fasteners in narrow spaces with obstacles.

The head of the offset wrench is bent at a certain angle from the handle. The angle design keeps your hand away from obstacles while keeping the wrench head aligned with the fastener. Both ends feature either a socket or open-end attachment. The offset design elevates the handle higher than a standard wrench, clearing nearby components.

This provides knuckle clearance in tight positions and improves access to fasteners obstructed by other components. The offset angle is typically 15 degrees, enabling mechanics to operate in complex mechanical environments where traditional straight-handle wrenches are ineffective.

Plier Wrench

Design: Adjustable parallel smooth jaws, combining pliers adjustment and wrench grip functionality

Best suited for: Pipes and precision fittings requiring surface protection

The pliers wrench features smooth parallel jaws that adjust like pliers but grip like a wrench. A button adjusts the jaw width, and squeezing the handle applies powerful parallel pressure on the fastener. The smooth jaws do not damage the chrome-plated or polished surfaces on pipes, fittings, and precision nuts.

Leverage amplifies hand strength, so you need less force to grip and turn stubborn fasteners. This design is particularly suitable for plumbing work where protecting the appearance of fittings is critical while still requiring sufficient grip strength to effectively turn fasteners.

Allen Wrench/Hex Key

Design: L-shaped hexagonal design, with one end featuring a long arm for torque and the other end a short arm for access.

Best suited for: Tightening and loosening hex socket screws and bolts.

The Allen Wrench (or hex key) features an L-shaped hexagonal design, suitable for hex socket head screws and bolts. One end has a longer arm for access and torque, while the shorter end is designed for use in narrow spaces. SAE and metric Allen Wrenches are sold in sets because each wrench is only suitable for one size.

Allen Wrenches are extremely common in furniture assembly, bicycle repair, and many modern devices. The L-shaped design allows users to choose between using the long arm for greater torque or the short arm for working in confined spaces. Hex socket fasteners are becoming increasingly popular due to their compact head design and high torque transmission capability.

Pipe Wrench

Design: Serrated adjustable jaws, with an adjustable upper jaw and a fixed lower jaw, specifically designed for gripping round pipes

Best suited for: Gripping and rotating round threaded pipes and pipe fittings

The pipe wrench uses its serrated, offset jaws to grip and rotate round threaded pipes and pipe fittings. The upper jaw is adjusted via a rotating ring, while the lower jaw remains fixed. The teeth bite deeper into the pipe surface as more rotational force is applied. The long handle provides leverage for stubborn pipes, and the jaws automatically tighten during use.

The serrated teeth leave marks on the pipe surface, so this wrench is primarily used for rough pipe work rather than precision fittings. Pipe wrenches are often mistakenly referred to as monkey wrenches, but monkey wrenches are older adjustable wrench designs with straight handles and smooth jaws, while pipe wrenches are specifically designed for round pipes.

Basin Wrench

Design: Long T-shaped handle with a curved serrated jaw at the end, resembling the top of the letter “S.”

Best suited for: Repairing fixtures under sinks and toilets.

If you want to repair the area under a sink, toilet, or washbasin, you will need a basin wrench. This type of wrench has serrated jaws, which help provide a better grip. The other end has a horizontal handle. This wrench is also known as a faucet wrench.

At first glance, this wrench may seem unusual. In fact, many people might think it is just a regular wrench. It has a long T-shaped handle with a curved jaw, resembling the top of the letter “S.” This type of wrench is primarily used for repairing leaks under faucets and sinks, which is why it is sometimes called a “faucet wrench.”

Pedal Wrench

Design: Slim open-end design, typically featuring one or two U-shaped grooves on the side of the head

Best suited for: Maintenance and repair of pedals on bicycles, scooters, or pedal boats

The name “pedal wrench” is aptly chosen, as this type of wrench is specifically designed for pedal-related tasks. You are most likely to find pedal wrenches in bicycle repair shops, though some amusement park maintenance personnel may also use them for repairing or maintaining scooters or pedal boats.

Pedal wrenches typically have one or two U-shaped grooves on the side of the head. They are commonly used for repairs involving pedals, which is not surprising. You are most likely to see them used on bicycles, but they may also be necessary for other repairs. Some festivals and amusement park rides also require these wrenches for maintenance.

Dog Bone Wrench

Design: A narrow handle connects two heavy-duty heads, each with multiple sockets of different sizes.

Best suited for: Bicycle repair and maintenance.

A common configuration in bicycle repair shops, dog bone wrenches are sometimes called dumbbell wrenches because of their dog bone or dumbbell shape. This type of wrench has a narrow handle that stretches between two heavy-duty heads. Each box-shaped head contains multiple sockets of different sizes, making the dog bone wrench a versatile choice for quick bicycle repairs.

This type of wrench can be used on objects other than bicycles, provided the sockets match the size of the fasteners. The dog bone wrench’s multi-socket design makes it an ideal tool for bicycle mechanics, as bicycles typically use a variety of different-sized fasteners, and this wrench can handle multiple sizes without the need to carry multiple separate tools.

Cone Wrench

Design: Ultra-thin metal plate with square openings at both ends, specifically designed for cup-and-cone bearings

Most suitable for: Bicycle bearing adjustment and appliance leveling foot adjustment

Although cone wrenches are most commonly found in bicycle repair shops, they can also be included in some household appliances for adjusting leveling feet. These wrenches are essentially thin metal plates with square openings at both ends, used to tighten or loosen the cone of cup-and-cone bearings on bicycles.

Imagine an open-end wrench flattened by an elephant, and you have a cone wrench. These wide, flat wrenches are used on the cone-shaped portion of cup-and-cone hubs. They are primarily used for bicycles or adjusting washing machine leveling feet, but are occasionally used for other delicate projects where a standard open-end wrench is too thick.

Lug Wrench

Design: This is a wrench with an L-shaped or X-shaped design, featuring a specialized socket head for wheel nuts.

Best suited for: Removing or reinstalling car wheels.

Most people have or should have a lug wrench in their vehicle in case of a flat tire. These tools are specifically designed to tighten and loosen the large tire nuts that secure the wheels to the vehicle. Lug Wrenches are typically about one to two feet long and feature an L-shaped design. However, similar to the L-shaped Lug Wrench style, you can also find X-shaped Lug Wrenches, which have four different-sized socket heads instead of just one.

A lug wrench is a tool that drivers are very familiar with. The L-shaped design provides sufficient leverage to loosen tire nuts that are often tightly secured, while the multiple socket sizes of the X-shaped version make it suitable for different vehicles. This is an essential tool for roadside emergencies.

Flare Nut Wrench

Design: Similar to an open-end wrench but with a wider opening that almost completely surrounds the nut, leaving only a small opening for the pipe to pass through

Best suited for: Gripping and tightening flared nuts at the ends of pipes, pipe and brake system repairs

The Flare Nut Wrench is designed for gripping and tightening flare nuts at the ends of pipes. It resembles an open-end wrench but with a wider opening. This wrench grips flare nuts without damaging them, making it the preferred tool for fuel line and brake system repairs.

The Flare Nut Wrench is specifically designed for securing soft metals (such as brass fittings) in pipe and automotive applications. Its unique design provides more contact area around the nut than a standard open-end wrench, reducing the risk of stripping or damaging precision threaded fittings. This is particularly important in hydraulic and fuel systems, where leaks can be hazardous.

Striking Wrench

Design: Heavy-duty design, specifically designed to withstand hammer blows, typically more robust than standard wrenches

Best suited for: Releasing stuck or rusted fasteners

The purpose of a striking wrench is to apply significant force to stuck or rusted fasteners to remove them. Heavy-duty striking wrenches are heavy-duty tools used with a hammer to apply greater torque to larger fasteners. This wrench is specifically designed to withstand hammer strikes without breaking or deforming.

Impact wrenches are commonly used in industrial environments where fasteners may become extremely difficult to remove due to corrosion, over-tightening, or prolonged exposure to harsh conditions. Their robust construction allows for the application of forces far exceeding the safety limits of standard wrenches, making them invaluable tools for heavy-duty maintenance and demolition work.

Spark Plug Wrench

Design: T-shaped handle design with specialized sockets at both ends, specifically designed for the hexagonal head of spark plugs

Best suited for: Adjusting and replacing spark plugs in internal combustion engines

The Spark Plug Wrench is a double-ended wrench with a T-shaped handle. It is used to adjust spark plugs in internal combustion engines, such as those found in cars and lawnmowers. The Spark Plug Wrench is typically part of a car tool kit. As you might guess, this type of wrench is used for spark plugs.

If you need to remove spark plugs from any location, including lawnmowers and smaller machines, you may require this wrench. However, unless you perform maintenance on your own vehicle or other vehicles, you may not need this tool. Spark Plug Wrenches are commonly found in repair shops and automotive repair facilities. The T-shaped design provides excellent grip and torque control, which is crucial for properly installing spark plugs without damaging the threads.

Fan Clutch Wrench

Design: Single-ended flat design, with a U-shaped opening at one end; some models have a square opening at the other end

Best suited for: Removal and installation of automotive fan clutches

As the name suggests, the Fan Clutch Wrench is specifically designed for removing fan clutches from vehicles. The Fan Clutch Wrench features a U-shaped opening at one end, with some designs including a square opening at the opposite end, making it ideal as a clamp-holding tool when another tool is used to turn hex nuts.

The Fan Clutch Wrench is a specialized tool in automotive maintenance, particularly when working on engine cooling systems. This flat, single-ended wrench allows technicians to work in the confined spaces of an engine compartment where standard wrenches may not fit. The Fan Clutch Wrench’s specialized design ensures proper grip on the fan clutch assembly, preventing damage during removal.

Strap Wrench

Design: Adjustable ring strap or chain connected to a sturdy handle, made of rubber, chain, or metal

Best suited for: Gripping and turning round objects such as oil filters

The Strap Wrench features an adjustable ring connected to a sturdy handle. The ring can be made of rubber, chain, or metal, depending on the application. The purpose of the Strap Wrench is to grip and turn oil filters in automotive maintenance. The Strap Wrench resembles an electric drill and comes in two styles.

You can also find chain-type oil filter wrenches and belt-type oil filter wrenches, which form a tight ring around the oil filter to tighten or loosen it. The wrench is particularly useful because it can grip smooth, round, or irregularly shaped objects that traditional wrenches cannot effectively grip. The rubber version is particularly suitable for polished surfaces, as it will not scratch or damage the finish.

Oil Filter Wrench

Design: Specially designed clamping tools, available in three main types: cup-type, chain-type, and belt-type

Best suited for: Loosening and tightening automotive oil filters

The Oil Filter Wrench is specifically designed for loosening and tightening oil filters. It enables automotive professionals and experienced DIY enthusiasts to quickly and efficiently perform oil changes on various vehicles. These wrenches feature a short side and a long circular side that wraps around the oil filter and securely grips it.

You can also find chain-type oil filter wrenches and belt-type oil filter wrenches, which form a tight ring around the oil filter to tighten or loosen it. These tools address the challenge of gripping oil filters due to their round, smooth surfaces, which are difficult to grasp with standard tools. Different types of oil filter wrenches are suitable for various filter sizes and installation locations, making them indispensable specialized tools for automotive maintenance.

Alligator Wrench

Design: Upper jaw serrated, lower jaw smooth, handle sharp like fangs, specifically designed for square heads

Most suitable for: Historically used for square nuts and bolts (now rare)

The Alligator Wrench was once the king of wrenches. The Alligator Wrench is named for the way it grips nuts. The upper jaw is serrated, while the lower jaw is smooth. The handle resembles sharp fangs rather than its modern counterpart, the pipe wrench. Since these were primarily designed for handling square heads, they are rarely seen outside of movies.

The alligator wrench represents an early stage in wrench development, when square nuts and bolts were more common than today’s hexagonal fasteners. Its unique combination of serrated and smooth jaws provided a strong grip on square fasteners, but as standardization shifted toward hexagonal fasteners, this design became obsolete. Today, they primarily appear as antique tool collectibles.

Armorer’s Wrench

Design: C-shaped serrated head, single-piece wrench with square slot and/or hole for connecting ratchet handle

Best suited for: Firearm maintenance and repair

This Armorer’s Wrench features a C-shaped serrated head, which may include square slots and/or holes for connecting a ratchet handle. Used for firearm maintenance and repair, they come in various designs and are typically manufactured in specific sizes to fit particular types or models of firearms.

Armorer’s Wrenches are highly specialized tools designed for firearm manufacturers, armorer’s, and firearm enthusiasts. Each Armorer’s Wrench is typically customized for specific firearm systems or components, such as barrel nuts, stock tubes, or other specialized fasteners. Their precise design ensures proper maintenance of expensive and precision firearm components without causing damage.

Bionic Wrench

Design: A circular opening paired with two plier-like handles that tighten when squeezed to form an adjustable hex wrench.

Best suited for: Universal gripping of fasteners of various sizes.

This is a specialized wrench with a circular opening and two plier-like handles. When placed around the target head, squeezing the two handles causes the opening to tighten and securely grip the head, transforming it into an adjustable hex wrench.

The Bionic Wrench looks unusual. Many people might not even guess it’s a wrench. This tool is a hybrid of pliers and a wrench. Therefore, when you squeeze the handles together, the opening tightens. Since the Bionic Wrench is adjustable, it can be used for various different heads, but there are often better flexible options available, so the Bionic Wrench isn’t used very often.

Drum Bung Wrench

Design: Socket-style design, specifically tailored to the shape of plastic or metal plugs on drums or barrels

Best suited for: Removing plastic or metal plugs from drums or barrels

Available in multiple styles, the Drum Bung Wrench is a socket-style wrench. It is specifically designed for removing plastic or metal plugs (caps) from drums or barrels. A special “spark-free” version is available for use with flammable materials.

The Drum Bung Wrench is designed for removing plastic or metal plugs from drums or barrels, as its name suggests. When working with flammable materials, you can choose from several spark-free or non-sparking options. The Drum Bung Wrench is indispensable in industrial environments where safe handling of various liquids and chemicals is critical.

Hook and Pin Spanner

Design: Hook and pin design, specifically for round objects with grooves or holes

Best suited for: Adjusting cylindrical objects, such as sealing nuts and hydraulic cylinders

This highly specialized tool resembles a hook or sickle. The Hook and Pin Spanner features a pin, enabling its use on various items. However, the Hook and Pin Spanner is rarely used today. You may not encounter or need to purchase one. The design of the Hook and Pin Spanner makes it ideal for tightening and loosening objects with grooves or holes.

The Hook and Pin Spanner is used for adjusting cylindrical objects, such as sealing nuts and hydraulic cylinders. Its hook and pin design makes it ideal for tightening and loosening objects with grooves or holes. In industrial applications requiring precise adjustment of circular components, this specialized tool offers functionality that standard wrenches cannot provide. Despite its limited用途, the Hook and Pin Spanner is indispensable in specific mechanical and hydraulic applications.

Flexible Head Wrench

Design: Flexible joint head design that can be bent and adjusted at multiple angles

Best suited for: Fasteners in narrow locations where flexibility is required

The Flexible Head Wrench is designed for accessing narrow spaces where flexibility is required. Its articulated tip enables easier access to awkward areas where standard wrenches are ineffective. The wrench’s jointed design allows the head to be positioned at various angles relative to the handle, providing unmatched accessibility in complex mechanical environments.

The Flexible Head Wrench is particularly suitable for automotive repair, aviation maintenance, and industrial machinery work, where fasteners are often located in hard-to-reach positions, obstructed by other components, pipes, or structural elements. The Flexible Head Wrench’s flexibility enables technicians to perform repairs without disassembling surrounding components, saving significant time and labor.

T-Handle Wrench

Design: T-handle design provides additional leverage and better grip control

Ideal for: Nut and bolt tightening requiring precise control

The T-Handle Wrench design provides additional leverage, making it easier to drive nuts and bolts with precision. The T-Handle Wrench offers convenience for tightening nuts and bolts. The T-shaped handle design provides additional leverage, making it easier to drive nuts and bolts with precision.

The T-Handle Wrench design allows users to operate with both hands, with one hand stabilizing the wrench and the other applying rotational force. This configuration is particularly useful when precise control is required or when fasteners require significant torque. The T-shaped handle also provides a more comfortable grip, reducing hand fatigue during prolonged use, making it the preferred choice for professional mechanics and technicians.

Summary

After a detailed introduction, we have covered 32 different types of wrenches, ranging from the most basic adjustable wrenches to highly specialized joint wrenches.

Each wrench has its unique design features and most suitable applications, embodying the philosophy of “specialized tools for specialized work.” From simple open-end wrenches to complex joint wrenches, these 32 typs of wrechse form a comprehensive tool system for modern mechanical maintenance and engineering work.

This complete family of wrenches demonstrates how the tool manufacturing industry continuously adapts and meets the increasingly specialized technical demands of various industries.