Every toolbox tells a story, and the screwdriver writes the opening chapter. This humble yet revolutionary tool has been turning screws—literally and figuratively—since the 15th century. But what exactly is a screwdriver, and why does every DIY enthusiast, professional mechanic, and weekend warrior need to understand its intricate details?

Whether you’re assembling furniture, repairing electronics, or building custom projects, understanding screwdrivers isn’t just helpful—it’s essential. This comprehensive guide will explore everything from basic definitions to advanced selection criteria, ensuring you never face a screw-related challenge unprepared.

What is a Screwdriver: The Essential Definition

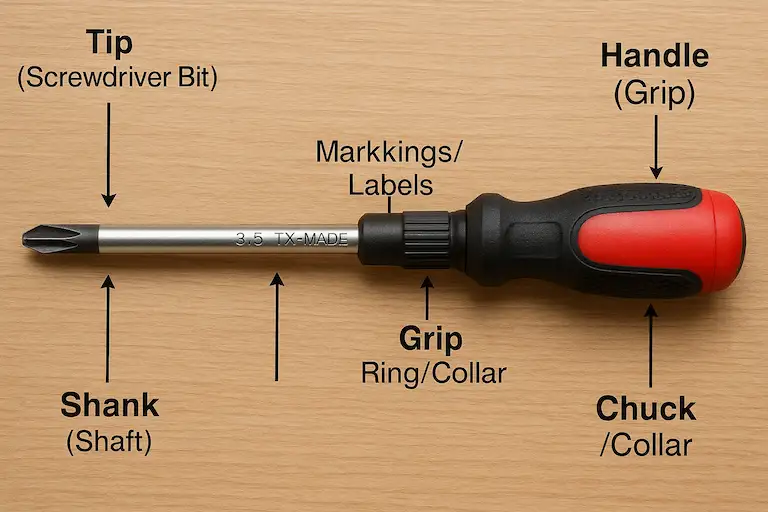

A screwdriver is a hand tool specifically designed to turn screws by applying rotational force through a handle to a shaft ending in a specially shaped tip. The fundamental principle seems simple: human force transforms into precise rotational energy. Yet this elegant mechanical solution has revolutionized how we fasten, assemble, and construct virtually everything around us.

The tool consists of three critical components working in perfect harmony. The handle provides grip and leverage, allowing users to apply controlled force. The shaft transfers this energy from hand to screw. The tip, engineered to match specific screw head designs, ensures optimal force transmission while preventing damage to both screw and tool.

Modern screwdrivers operate on basic physics principles—specifically torque multiplication and mechanical advantage. When you grip the handle and twist, you’re creating rotational force that travels down the shaft and into the screw head. The wider the handle, the greater the mechanical advantage, which explains why professional-grade screwdrivers often feature oversized grips.

What makes a screwdriver truly effective isn’t just its ability to turn screws. The tool must also provide precise control, resist slipping, and maintain consistent performance across thousands of uses. Quality screwdrivers feature hardened steel tips that resist wear, ergonomic handles that reduce hand fatigue, and precision-machined surfaces that ensure perfect screw engagement.

Types of Screwdrivers: Complete Classification

Understanding screwdriver types transforms confusion into confidence. Each design serves specific purposes, and knowing when to use which type can mean the difference between successful completion and frustrating failure.

What is a Phillips Screwdriver

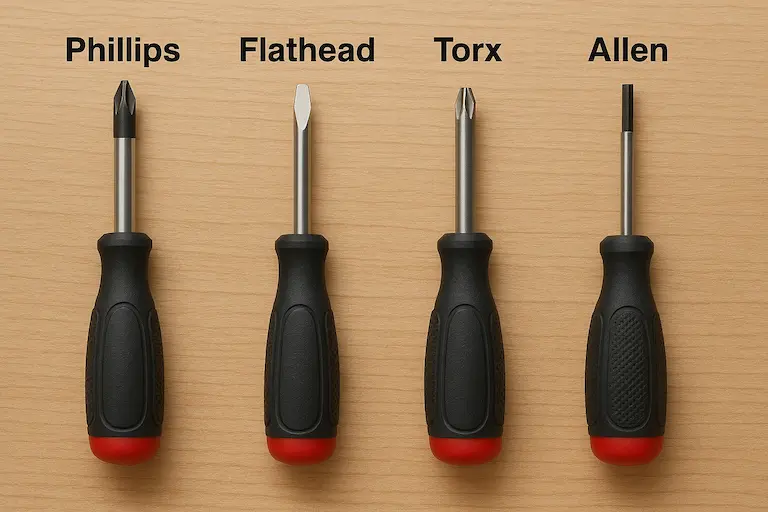

The Phillips screwdriver, invented by Henry Phillips in 1936, features a distinctive cross-shaped tip designed to engage with Phillips head screws. This revolutionary design solved a critical problem: preventing over-tightening by allowing the driver to “cam out” when excessive torque is applied.

Phillips screwdrivers come in numbered sizes from #0 to #4, with #2 being the most common for general household use. The cross-shaped tip distributes force across four contact points, reducing the likelihood of screw head damage and providing superior grip compared to slotted alternatives.

What is a Flathead Screwdriver

Also known as a slotted screwdriver, this original design features a flat, blade-like tip that fits into straight-line slots. Despite being the oldest screwdriver type, flathead screwdrivers remain indispensable for specific applications where precision and simplicity matter most.

The flat tip design allows for alternative uses beyond screw-turning: prying, scraping, and even light chiseling work. Professional electricians often prefer flathead screwdrivers for terminal screws, while antique restoration specialists rely on them for period-appropriate hardware.

What is a Torx Screwdriver

Torx screwdrivers feature a six-pointed star-shaped tip that provides exceptional torque transfer while minimizing cam-out risk. Originally developed for automotive applications, Torx screws and their corresponding drivers have expanded into electronics, appliances, and high-performance machinery.

The star-shaped design distributes force across six contact points rather than four, allowing for higher torque application without screw head damage. Torx sizes are designated by “T” numbers, with T10, T15, and T25 being most common in general applications.

What is an Allen Screwdriver

Allen screwdrivers, also called hex keys or hex drivers, feature hexagonal tips designed for Allen head screws. These six-sided tools provide excellent torque transfer and are virtually immune to cam-out, making them ideal for high-stress applications.

Available in both metric and imperial sizes, Allen screwdrivers are essential for furniture assembly, bicycle maintenance, and machinery repair. The hexagonal design ensures even force distribution and extended tool life under demanding conditions.

Specialized Screwdriver Types

Beyond the basic four, specialized screwdrivers address specific needs. Impact screwdrivers combine rotational force with percussive action, making them perfect for seized or stubborn screws. Ratcheting screwdrivers eliminate the need for hand repositioning, dramatically improving efficiency in repetitive tasks.

Precision screwdrivers, designed for electronics and delicate work, feature smaller tips and refined control. Insulated screwdrivers provide electrical safety for electrical work, while magnetic-tip versions prevent screw dropping in awkward positions.

What Are Screwdrivers Used For: Applications & Uses

Screwdrivers serve as universal problem-solvers across countless scenarios. Their applications span from simple household tasks to complex industrial operations, proving their versatility and indispensable nature.

Household Applications

In domestic settings, screwdrivers tackle everything from loose door hinges to electronic device repairs. Kitchen appliances, bathroom fixtures, and furniture assembly all depend on proper screwdriver selection and technique. The average household uses screwdrivers for approximately 15-20 different tasks monthly, from changing batteries to adjusting cabinet doors.

Home improvement projects often demand multiple screwdriver types. Installing light fixtures requires both flathead and Phillips drivers, while assembling furniture might need Allen keys and specialty drivers. Understanding which tool fits which task prevents frustration and ensures professional-quality results.

Professional Applications

In automotive repair, screwdrivers access engine components, electrical systems, and body panels. Mechanics rely on impact drivers for rusted bolts and precision drivers for delicate sensors. The automotive industry specifically drives innovation in screwdriver design, demanding tools that withstand extreme conditions while maintaining precision.

Electronics manufacturing and repair require specialized screwdrivers capable of handling miniature components without causing damage. Torx and pentalobe drivers dominate this space, where precision matters more than raw force.

Industrial and Construction Uses

Construction professionals use screwdrivers for everything from drywall installation to electrical work. Heavy-duty models withstand jobsite abuse while maintaining performance. Industrial applications often require specialized drivers for equipment maintenance and assembly line work.

The construction industry’s evolution toward more complex fastening systems has driven screwdriver innovation. Modern construction projects might require dozens of different screwdriver types, each optimized for specific materials and applications.

How to Choose the Right Screwdriver for Your Needs

Selecting the perfect screwdriver isn’t guesswork—it’s strategic decision-making based on specific criteria. The right choice dramatically impacts project success, user comfort, and long-term tool performance.

Discover the best multi-bit screwdrivers

Consider Your Primary Applications

Professional mechanics need different tools than weekend DIYers. Heavy-duty automotive work demands robust handles and hardened tips that withstand high torque applications. Electronics enthusiasts require precision instruments with fine tip control and anti-static properties.

Frequency of use significantly influences selection criteria. Daily users benefit from premium materials and ergonomic designs that reduce fatigue. Occasional users might prioritize versatility over specialized features, focusing on multi-bit sets that handle various tasks efficiently.

Quality Indicators to Evaluate

Handle construction reveals tool quality immediately. Premium screwdrivers feature molded grips with textured surfaces that provide secure hold even with wet or oily hands. Cheap alternatives often use slippery plastic that becomes dangerous under pressure.

Tip hardness and precision machining separate professional tools from hardware store impulse purchases. Quality tips maintain their shape through thousands of uses, while inferior versions round off quickly, leading to screw damage and user frustration.

Size and Set Considerations

Individual screwdrivers work well for specialized tasks, but most users benefit from comprehensive sets. A quality 10-piece set typically includes multiple Phillips sizes, several flathead options, and basic specialty drivers. This covers approximately 85% of common household and light professional applications.

Professional-grade sets expand to 20-40 pieces, incorporating specialized drivers for specific industries. Automotive sets emphasize Torx and hex drivers, while electronics sets focus on precision instruments and anti-static features.

Learn more about ratcheting wrenches

Screwdriver Usage Tips & Best Practices

Proper technique transforms good tools into exceptional results. Understanding correct usage prevents damage, improves efficiency, and extends tool life significantly.

Grip and Positioning Fundamentals

The three-finger grip provides optimal control for most applications. Thumb and forefinger control the handle while the middle finger provides stability. This grip allows precise force application without causing hand fatigue during extended use.

Body positioning matters enormously. Align your body with the screw axis to apply straight, consistent force. Awkward angles cause tip slippage and potential injury. When possible, position yourself to push rather than pull, providing better control and reduced accident risk.

Avoiding Common Mistakes

Over-tightening destroys both screws and drivers. Learn to recognize when screws are properly seated—they should feel snug without requiring excessive force. Stripped screws usually result from wrong-sized drivers or excessive torque application.

Using worn or damaged drivers guarantees poor results. Inspect tips regularly for rounding, chipping, or wear. Replace damaged tools immediately rather than struggling with inferior performance that often causes additional damage.

Understanding different types of ratcheting wrenches

Maintenance and Storage

Clean tools after each use, especially when working with corrosive materials. Oil or grease residue attracts dirt and can cause handle slippage. Store screwdrivers in organized systems that protect tips from damage while keeping them easily accessible.

Magnetic tool holders work excellently for steel-shanked drivers, while foam-lined drawers protect precision instruments. Avoid throwing tools loose in toolboxes where they can damage each other through contact and vibration.

Understanding Screwdriver Materials and Manufacturing

Quality screwdrivers combine advanced metallurgy with precision manufacturing. The shaft typically uses chrome-vanadium steel, heat-treated to achieve optimal hardness without brittleness. This material provides excellent durability while maintaining the flexibility needed for demanding applications.

Handle materials vary significantly based on intended use. Professional-grade tools often feature multiple materials—hard plastic cores for strength, soft rubber exteriors for grip, and sometimes metal reinforcement for extreme-duty applications. The best handles distribute force evenly, reducing pressure points that cause discomfort during extended use.

Tip manufacturing involves precision machining followed by heat treatment. The tip must be harder than the screws it drives while retaining enough toughness to resist chipping. This balance requires sophisticated metallurgical knowledge and quality control processes.

The Evolution of Screwdriver Design

Modern screwdrivers represent centuries of incremental improvement. Early versions were simple flat blades, often improvised from available materials. The industrial revolution brought standardized manufacturing and consistent quality.

The Phillips head revolution in the 1930s addressed automotive assembly line needs. Workers could drive screws more quickly and consistently while the cam-out feature prevented over-tightening that could damage materials. This design philosophy continues influencing modern fastener development.

Recent innovations focus on ergonomics and efficiency. Ratcheting mechanisms eliminate hand repositioning, while magnetic tips prevent screw dropping. Some models incorporate LED lights for improved visibility in tight spaces.

Specialized Applications and Professional Considerations

Different industries have developed specialized screwdriver requirements. Electricians need insulated tools rated for specific voltages. Electronic technicians require anti-static properties and precision tips. Automotive professionals need tools that withstand chemicals and extreme temperatures.

The medical device industry demands screwdrivers that can withstand sterilization processes while maintaining precision. Aerospace applications require tools that function in extreme temperatures and won’t outgas in vacuum environments.

These specialized requirements drive continuous innovation in materials and design. What starts as industry-specific innovation often migrates to general-purpose tools, improving performance for all users.