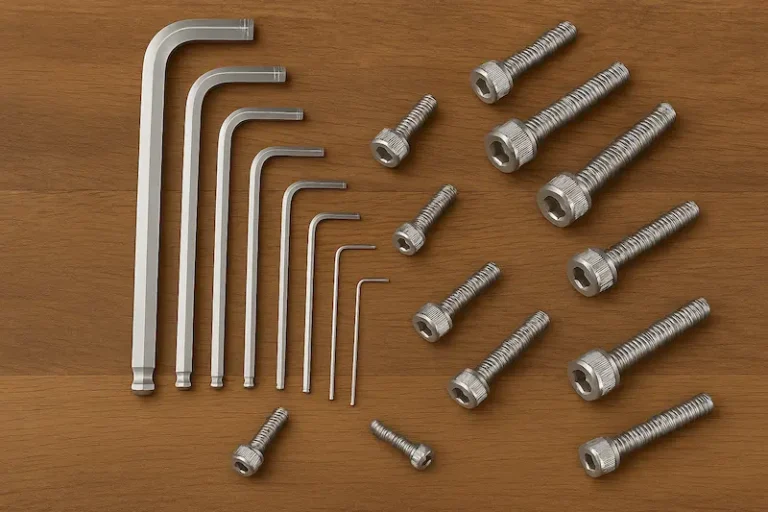

Have you ever wondered who invented the hex wrench? This great innovation originated from the creator’s personal experience of witnessing work accidents that claimed the lives of workers, which led him to begin researching tools that could prevent such accidents. Engineer William G. Allen designed and invented the hex wrench in 1910, making a significant contribution to preventing accidents caused by exposed nuts. Below, we will recount this story in detail.

Who Invented the Allen Wrench?

Ever wondered who invented the allen wrench? This life-saving innovation emerged from a workplace tragedy that claimed too many workers’ lives. In 1910, a brilliant engineer named William G. Allen revolutionized industrial safety with a simple yet ingenious design that would transform mechanical work forever.

The allen wrench wasn’t just another tool invention—it was born from necessity, tragedy, and the desperate need for workplace safety in America’s booming industrial age. Allen’s hexagonal socket design solved a deadly problem that had plagued factories for decades.

William G. Allen: The Safety-Minded Inventor Who Changed Wrench

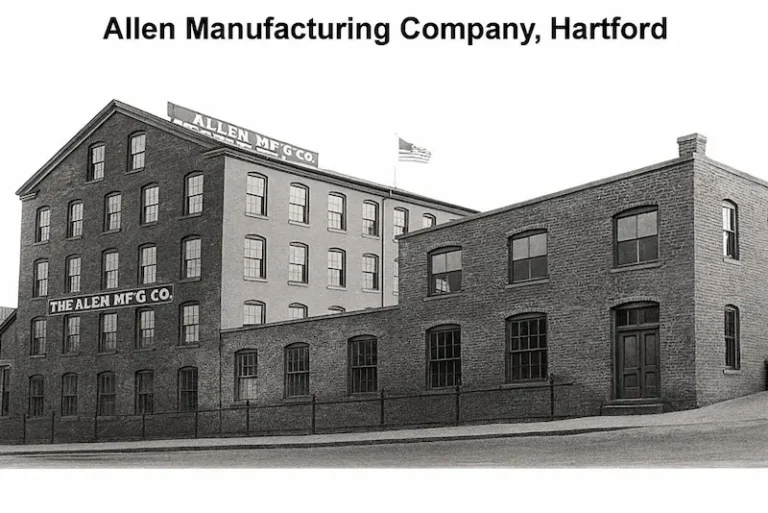

William G. Allen founded the Allen Manufacturing Company in 1910 in Hartford, Connecticut, driven by a mission that went far beyond simple tool-making. Allen witnessed firsthand the horrific accidents caused by conventional set screws, and his invention would save countless lives while revolutionizing industrial fastening.

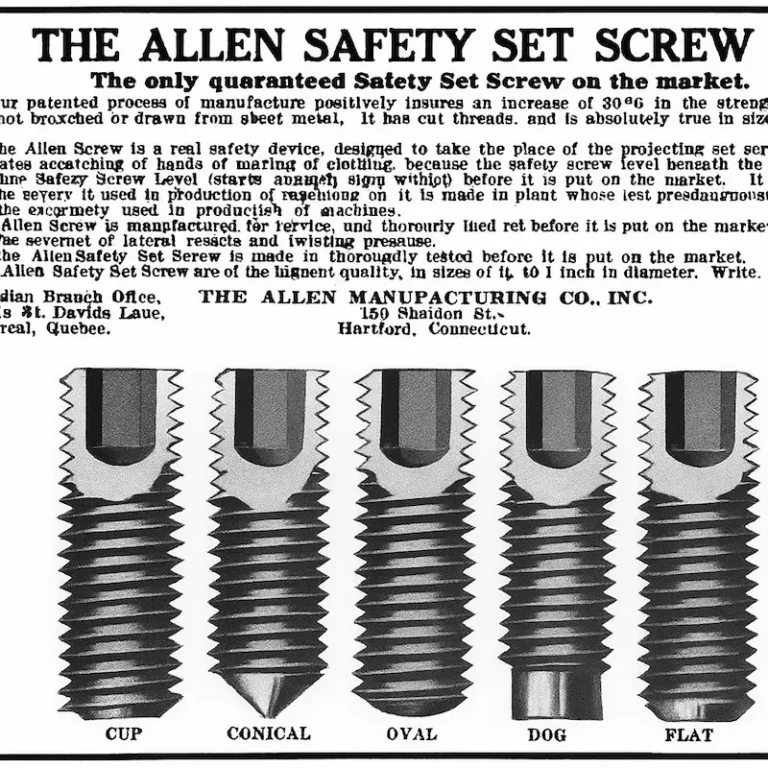

The conventional set screws of Allen’s era (1910s) featured square heads that projected dangerously above machinery surfaces. Workers’ clothing frequently snagged on these protruding heads, resulting in what contemporary industrial reports called “gruesome accidents.” These incidents often led to severe injuries or death as workers were pulled into moving machinery.

Check the Complete Guide to Types of Ratcheting Wrenches: Everything You Need to Know in 2025

Allen’s breakthrough came through his revolutionary safety set screw design, which featured an internal hexagonal socket instead of an external square head. This design allowed screws to be tightened completely flush with or below the surface, eliminating the deadly projection that had claimed so many lives.

Patent 960,244, filed by W.G. Allen in 1909 and issued June 7, 1910, described his method of cold-forming a screw head around a hexagonal die. This wasn’t merely a new tool—it was a complete manufacturing process that created stronger, safer fasteners than any existing technology.

Allen’s early advertisements boldly promoted his products as “safety set screws” and positioned them as life-saving alternatives to conventional fasteners. The 1910 Annual Convention of the International Association of Factory Inspectors featured Allen’s advertisements, highlighting the patented cold-forming process that made these safety improvements possible.

The Allen Manufacturing Company‘s original focus was preventing industrial accidents, not creating convenience tools. Allen understood that worker safety required fundamental changes to fastener design, and his hexagonal socket concept addressed the root cause of machinery-related injuries.

As competition emerged from manufacturers using conventional broached hexagonal openings, Allen emphasized his patented process’s superior quality. His advertisements noted that Allen screws provided hexagonal sockets to the full depth, while broached alternatives suffered from accumulated metal chips that reduced engagement depth.

The Cold-Forming Revolution: Allen's Secret Manufacturing Process

Who invented the allen wrench becomes more fascinating

When examining Allen’s revolutionary manufacturing technique. The cold-forming process Allen developed in 1909 represented a quantum leap in metallurgy and manufacturing precision that wouldn’t become industry standard for decades.

Traditional fastener manufacturing relied on cutting, drilling, and broaching operations that weakened the metal structure. Allen’s cold-forming process forced steel socket blanks under tremendous pressure to flow around a precisely machined hexagonal mandrel, creating seamless internal geometry without removing any material.

This process produced several critical advantages over conventional manufacturing methods. The cold-forming technique created continuous grain flow throughout the fastener, dramatically increasing strength and durability. The hexagonal socket achieved perfect dimensional accuracy since it was formed rather than cut.

Allen’s 1910 patent described forcing steel “to flow around a mandrel” under what contemporary sources called “great pressure.” This technique required sophisticated hydraulic equipment and precision tooling that few manufacturers possessed, giving Allen a significant competitive advantage.

The cold-forming process also eliminated the metal chips and burrs that plagued broached fasteners. Conventional broaching accumulated chips inside hexagonal sockets, reducing the effective engagement depth and compromising tool fit. Allen’s formed sockets maintained full depth engagement.

Industrial historians recognize Allen’s cold-forming technique as the dominant process for socket production today, though it was revolutionary in the 1920s. Allen Manufacturing remains the only known company to have used this advanced technique during the early decades of the twentieth century.

The manufacturing sophistication required for Allen’s process explains why competitors initially struggled to replicate his products’ quality. Simple broaching operations could create hexagonal openings, but they couldn’t match the precision, strength, and reliability of Allen’s cold-formed sockets.

From Safety Innovation to Universal Tool: The Allen Wrench Evolution

The transformation of who invented the allen wrench from safety pioneer to household name reflects America’s industrial evolution from the 1910s through the modern era. Allen’s safety-focused invention gradually became the world’s most versatile precision tool.

By the early 1920s, Allen Manufacturing was well-established as the premier maker of safety set screws and related hardware. Seeking to expand beyond industrial safety applications, Allen recognized the explosive growth in automotive service tools and decided to enter this rapidly expanding market.

Allen’s first automotive venture was a rim wrench advertised in the July 15, 1921 issue of Southern Hardware and Implement Journal. This represented Allen’s initial attempt to apply his cold-forming process to automotive tools, setting the stage for a complete line of socket wrench products.

The early 1920s automotive boom created unprecedented demand for high-quality socket sets. Heavy-wall turned and broached sockets were rapidly replacing older pressed steel alternatives, and Allen realized his cold-forming process could revolutionize interchangeable socket production.

Allen Manufacturing acquired the Bay State Pump Company around 1922, gaining access to established socket wrench distribution channels. This strategic acquisition allowed Allen to market socket sets under the “Bay State” brand name while leveraging his proprietary manufacturing technology.

The Allen “Bay State” socket sets represented the first application of cold-forming technology to interchangeable socket production. These sets featured sockets made entirely through Allen’s patented process, providing superior strength and precision compared to conventional broached alternatives.

Historical advertisements from 1922 specifically promoted “Allen Process Sockets” as a key differentiator. Motor Age and Popular Mechanics featured detailed descriptions of how Allen’s cold-forming technique created superior socket quality that competing manufacturers couldn’t match.

However, the Bay State venture proved short-lived, with advertisements disappearing after 1923 and production apparently discontinued by 1925. Allen likely realized that socket wrench manufacturing required different distribution strategies than industrial hardware sales.

The Allen Legacy: From Hartford to Global Standard

Understanding who invented the allen wrench reveals how a single safety innovation transformed into one of humanity’s most essential tools. William G. Allen’s 1910 patent laid the foundation for virtually every hexagonal fastening application used today.

In 1956, Allen Manufacturing became a subsidiary of Chicago Pneumatic, beginning a series of corporate transitions that would spread Allen’s technology worldwide. The 1986 acquisition by Danaher Corporation brought Allen’s manufacturing expertise into a major tool conglomerate with global reach.

Today, Allen Manufacturing continues as part of the Apex Tools Group, though the company’s focus has shifted from its original safety mission to general tool manufacturing. The Allen brand remains synonymous with hexagonal socket tools across multiple product categories.

The cold-forming process Allen pioneered in 1910 became the industry standard for socket production, though few manufacturers acknowledge this historical connection. Modern socket manufacturing relies entirely on the principles Allen developed over a century ago.

Allen’s original safety motivation has largely been forgotten, but his hexagonal socket design continues preventing accidents in modern applications. From furniture assembly to precision electronics repair, the flush-mounting capability that saved industrial workers’ lives now serves billions of daily applications.

The global impact of Allen’s invention extends far beyond simple tool manufacturing. Modern industries from aerospace to consumer electronics depend on hexagonal fasteners that trace their lineage directly to William G. Allen’s 1910 safety innovation.

Check The Ironcube tool guide hand tools that actually work

Conclusion: Remembering the Man Behind the Essential Tool

Who invented the allen wrench? William G. Allen, a safety-minded engineer whose 1910 patent saved countless lives while creating one of history’s most indispensable tools. His cold-forming process revolutionized manufacturing and established hexagonal fastening as the global standard.

Allen’s legacy reminds us that the greatest innovations often emerge from addressing fundamental human needs rather than pursuing technological novelty. His focus on worker safety led to a tool that now serves virtually every mechanical application imaginable.

From preventing gruesome industrial accidents to enabling modern furniture assembly, the allen wrench represents how thoughtful engineering can create lasting positive impact. Allen’s hexagonal socket design remains essentially unchanged after more than a century of continuous use.

The next time you reach for an allen wrench, remember William G. Allen’s original mission: creating tools that protect human life while advancing mechanical capability. His simple yet profound innovation continues serving humanity, proving that the most enduring inventions address our most basic needs for safety and precision.