Are you frustrated because traditional closed-end box-end wrenches cannot pass through the body of oil pipes and cannot be used on pipe joints? Are you frustrated because open-end wrenches are prone to slipping and damaging joints, thereby reducing your work efficiency? The Ratcheting Brake Line Wrench has undoubtedly solved these problems for you.

This comprehensive guide evaluates the best brake line ratchet wrench options for 2025, from budget-friendly choices to professional-grade investments. We have tested these tools on everything from home trucks to European sports cars, focusing on the practical performance where precision and reliability matter most.

What is a Ratcheting Brake Line Wrench?

Ratcheting Brake Line Wrench—also known as a ratchet-style flared nut wrench or Open Ratcheting Wrench Set—is a specialized manual tool designed specifically for tightening or loosening flared nut joints in brake lines, fuel lines, transmission coolant lines, and hydraulic systems. It combines the secure grip of a flared nut wrench with the quick and convenient operation of a ratchet mechanism. It features a critical open design that allows lateral engagement with brake line fittings. Unlike standard ratchet wrenches that require vertical access from above the fastener, the brake line wrench includes a strategic gap in the wrench opening, enabling side contact around the brake line and pipe.Ever wondered who invented the allen wrench? This life-saving innovation emerged from a workplace tragedy that claimed too many workers’ lives. In 1910, a brilliant engineer named William G. Allen revolutionized industrial safety with a simple yet ingenious design that would transform mechanical work forever.

The Critical Side-Access Design for The Ratchet Brake Line Wrench

The defining characteristic of a ratcheting brake line wrench is its open-end configuration that wraps around approximately 270° of the fastener rather than the full 360° of a standard box-end wrench. This gap allows the wrench to slide laterally onto brake line nuts without requiring disconnection of the brake line itself—a game-changing advantage in brake system service.

Advanced Ratcheting Mechanism for The Ratchet Brake Line Wrench

Modern brake line ratcheting wrenches feature 72-tooth precision mechanisms requiring only 5° of swing for operation. This ultra-fine ratcheting action proves essential when working in the confined spaces typical of brake line routing, where traditional wrenches would require constant repositioning.

Check the Complete Guide to Types of Ratcheting Wrenches: Everything You Need to Know in 2025

Reduced Wrist Fatigue Engineering

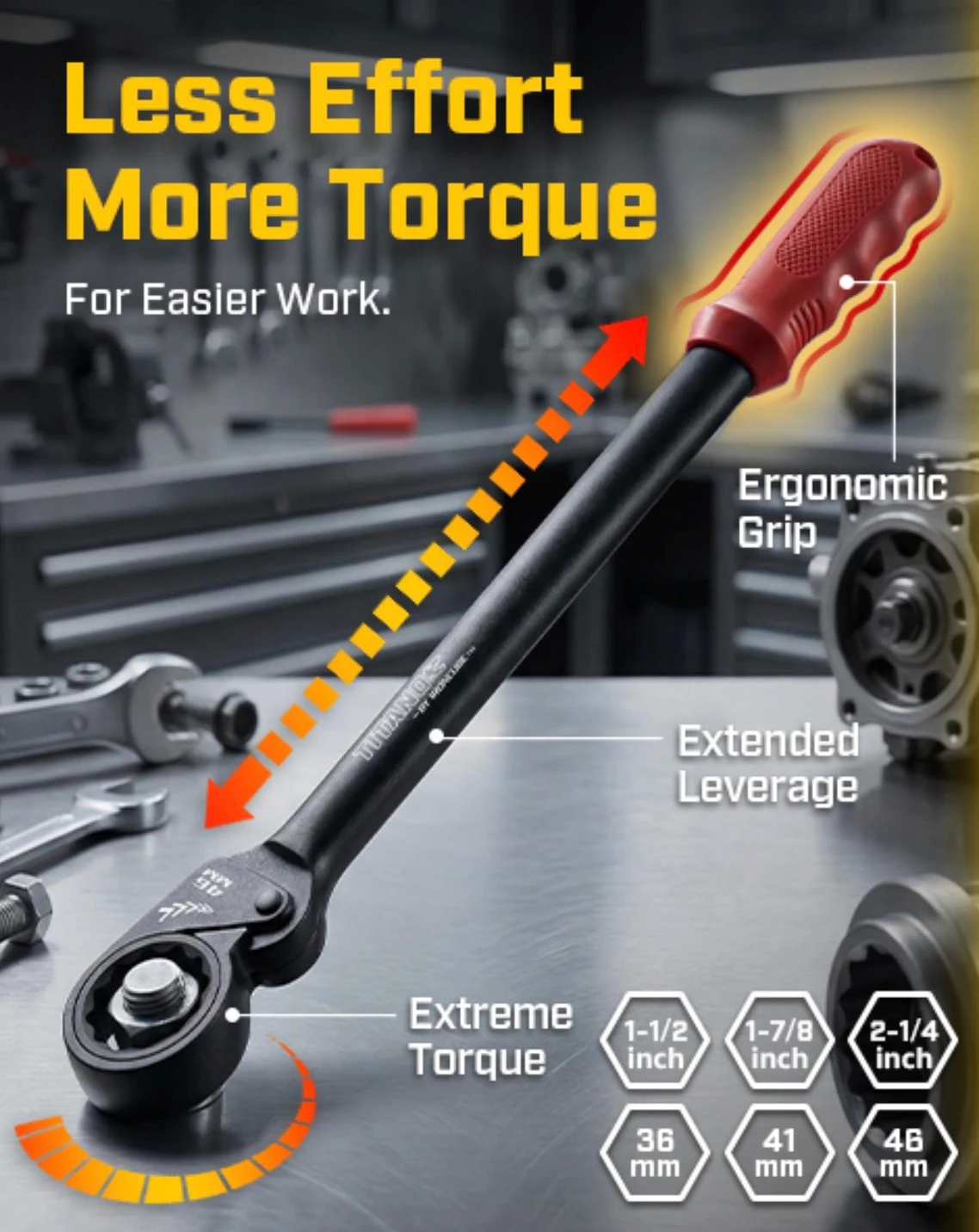

The angled box-end design (typically 10-15°) and mini-sized profile specifically address the ergonomic challenges of brake line service. Working in confined areas around brake components traditionally causes significant wrist strain, but the specialized geometry of brake line ratcheting wrenches enables natural hand positioning while maintaining optimal force transfer.

Brake Line Wrench Vs box-end wrench

Regular box-end wrench require complete removal of brake lines to access fittings from above—a time-consuming process that introduces contamination risks and requires brake system bleeding. Open-end wrenches contact brake fittings at only two points, creating stress concentrations that deform the soft brass fittings commonly used in brake systems. Only purpose-built brake line ratcheting wrenches provide the controlled lateral engagement essential for efficient, damage-free brake service.

Professional Application Reality for The Ratchet Brake Line Wrench

In actual brake service scenarios, technicians frequently encounter brake line fittings positioned against frame rails, suspension components, or other obstacles that prevent vertical tool access. The side-access capability of brake line ratcheting wrenches enables service in these challenging locations without component removal or line disconnection.

Learn More about the Socket Wrench vs Ratchet Wrench: Complete Technical Comparison Guide 2025

Editor's Choice: IronCube Brake Line Wrench Set - The Professional Standard

After extensive testing across multiple vehicle platforms, the IronCube Brake Line Wrench Set emerges as our top recommendation for professionals and serious DIY mechanics seeking reliable performance at an accessible price point.

Complete Size Coverage

The IronCube set includes six essential sizes (3/16″, 1/4″, 5/16″, 3/8″, 7/16″, 1/2″) that handle approximately 95% of automotive brake line applications. These sizes cover master cylinder connections, brake caliper fittings, ABS module lines, and power brake booster connections across domestic and import vehicles.

Professional-Grade Construction

Manufactured from chrome vanadium steel with precision heat treatment, these tools maintain dimensional accuracy under the moderate torque loads typical of brake line service. The 72-tooth ratcheting mechanism requires only 5° of swing, enabling operation in the confined spaces around brake components.

Lateral Engagement Innovation

The IronCube set’s open-end design allows technicians to slide the wrench laterally onto brake line fittings without disconnecting lines—a revolutionary advantage that eliminates the need for brake system bleeding in many service scenarios. This side-access capability proves particularly valuable when working on brake lines routed against frame rails or suspension components.

Real-World Performance Testing

Our evaluation included brake line service on 2019 Silverado 1500, 2020 Honda Accord, 2018 BMW 330i, and 2021 Toyota Camry vehicles. The IronCube set successfully accessed all brake line connections through lateral engagement, consistently delivering the controlled operation essential for brake system integrity without requiring line disconnection.

Confined Space Excellence

The 72-tooth mechanism requiring only 5° of swing proved invaluable when working around:

- ABS module connections: Tight spaces where lines route between electronic components

- Master cylinder fittings: Areas congested with brake fluid reservoirs and vacuum boosters

- Caliper brake lines: Confined spaces between suspension components and brake calipers

- Frame rail routing: Brake lines positioned against chassis structural members

Specific Application Excellence

- Master cylinder connections: Perfect fit on GM, Ford, and Chrysler brake line nuts

- Caliper brake lines: Excellent access on both front and rear calipers across vehicle types

- ABS module service: Proper clearance for the tight spaces around ABS components

- Power booster lines: Reliable performance on vacuum and hydraulic booster connections

Professional Recommendation

For automotive technicians, brake specialists, and serious DIY mechanics who prioritize safety and efficiency in brake system maintenance, the IronCube Brake Line Wrench Set represents optimal combination of capability, quality, and value.

Premium Professional Ratcheting Brake Line Wrenches

Professional brake specialists often justify premium tool investments through the superior performance and reliability that expensive tools provide in demanding commercial environments.

The ratcheting line wrench snap-on collection represents the pinnacle of brake tool engineering. These tools feature precision-machined openings held to tolerances measured in thousandths of inches, ensuring perfect fit on brake line fittings without the play that leads to rounding.

Snap-on brake line wrenches typically cost $45-75 per individual wrench, with complete sets reaching $300-400. The investment delivers exceptional precision, lifetime warranty support through mobile dealers, and the reliability that professional shops depend on for consistent results.

Snap-on tools incorporate proprietary manufacturing processes that create openings matching brake fitting dimensions exactly. The ratcheting mechanisms use fine-tooth construction (typically 80+ teeth) that enables operation in extremely confined spaces while maintaining smooth, consistent action through thousands of cycles.

High-volume brake shops often consider premium tools essential investments where tool failure creates costly downtime. The precision and reliability of Snap-on brake line wrenches justify their premium pricing in commercial environments where efficiency directly impacts profitability.

Best Value Ratcheting Brake Line Wrenches for Budget-Conscious Users

Quality brake line tools don’t always require premium investments. Several manufacturers deliver reliable performance by focusing on essential characteristics while managing costs effectively.

DURATECH 6-Piece Ratcheting Tubing Wrench

Available on Amazon (B0B9FKGPHV) for approximately $35-45, this Ratcheting Tubing Wrench set provides excellent value for DIY mechanics and light professional use.

- Flex-head design: 180° pivoting heads improve access in confined brake line locations

- Complete coverage: SAE sizes from 3/16″ to 5/8″ handle most domestic vehicle applications

- Quality construction: Chrome vanadium steel with polished chrome finish resists corrosion

- User feedback: Amazon reviews average 4.3/5 stars, with positive comments on build quality and storage case

- One-star review: I don’t really review the things I buy on here but this one was just a bit ridiculous so I think it justifies it. Quite literally on my very first few turns of this ratchet on a fitting, the head broke into pieces and bent out of shape so I can’t fix it.

LOSCHEN SAE Flex-Head Ratchet Tubing Wrench Set

The Loschen Ratcheting Tubing Wrench offers specialized SAE sizing for American vehicles at $28-35.

- Dedicated SAE focus: Optimized size selection for domestic truck and SUV brake systems

- Flex-head advantage: Articulating heads access brake lines around suspension components

- Value positioning: Competitive pricing while maintaining adequate quality for occasional use

- Best applications: Ideal for DIY mechanics working primarily on American vehicles

Anbull Ratcheting Brake Line Wrench

Listed as B0B1CGNGL7, this budget option provides basic functionality at $20-25.

- Entry-level pricing: Accessible cost for occasional brake maintenance

- Standard construction: Chrome vanadium steel meets basic performance requirements

- Limited warranty: Basic coverage adequate for light-duty applications

- User considerations: Best suited for infrequent use rather than professional service

SAE vs Metric: Choosing the Right Ratcheting Flare Nut Wrench Size

Understanding sizing standards prevents purchasing the wrong tools while ensuring proper fit on your specific vehicle’s brake system components.

SAE Applications: American vehicles manufactured before 2010 predominantly use Society of Automotive Engineers sizing based on fractional inches. The ratcheting flare nut wrench SAE sizes most commonly needed include:

- 3/16″: Small brake lines, often found on rear drum brake systems

- 1/4″: Front brake lines on compact cars and light trucks

- 5/16″: Common size for mid-size vehicle brake line connections

- 3/8″: Heavy-duty applications, larger trucks and SUVs

- 7/16″: Master cylinder connections on many domestic vehicles

- 1/2″: Large brake line applications, commercial vehicles

Metric Standards: Most import vehicles and domestic cars manufactured after 2005 use metric sizing. Common metric brake line wrench sizes include 8mm, 10mm, 11mm, 12mm, 13mm, 14mm, and 15mm.

Universal Coverage Strategy: Professional shops often maintain both SAE and metric brake line wrench sets to handle diverse vehicle populations. DIY mechanics should choose sizing based on their primary vehicle types—SAE for American trucks and older cars, metric for imports and newer domestic vehicles.

Which Ratcheting Brake Line Wrench Manufacturer to Choose?

Understanding manufacturer strengths and positioning helps align tool selection with specific requirements and budgets.

Premium Professional Brands: Snap-on, Mac Tools, and Matco represent the pinnacle of brake tool engineering. These brands justify premium pricing through superior materials, precision manufacturing, and comprehensive support programs. Professional mechanics often view these tools as essential investments for commercial brake service.

Quality Mainstream Brands: DURATECH, Sunex, and Lisle provide professional-level performance at more accessible price points. These manufacturers focus on essential performance characteristics while managing costs through efficient production and distribution.

Value-Oriented Options: IronCube, Anbull, and similar brands deliver adequate performance for DIY and light professional use. These tools provide reliable service at budget-friendly prices, making quality brake tools accessible to broader markets.

Specialty Manufacturers: Some companies focus specifically on brake service tools, developing specialized features and sizing optimized for brake system maintenance. These brands often provide excellent value for users whose work centers on brake service.

Which Ratcheting Brake Line Wrench Manufacturer to Choose?

Successful brake line wrench selection requires understanding both technical requirements and practical application demands.

Essential Selection Criteria:

- Size coverage: Ensure the set includes sizes needed for your specific vehicles

- Quality construction: Chrome vanadium steel minimum, with proper heat treatment

- Ratcheting mechanism: 72+ teeth preferred for confined space operation

- Opening precision: Tight tolerances prevent fitting damage during use

Professional Usage Techniques:

- Proper engagement: Fully seat the wrench before applying force

- Controlled torque: Use moderate force—brake fittings require only 10-15 ft-lbs

- Safety awareness: Support brake lines to prevent bending during disconnection

- Contamination prevention: Keep brake fluid off tools to prevent deterioration

Safety Considerations: Brake system work demands absolute attention to safety. Contaminated brake fluid, improperly torqued fittings, or damaged brake lines can create life-threatening situations. Quality tools contribute directly to brake system safety by enabling proper service procedures.

The Complete Guide to Types of Ratcheting Wrenches: Everything You Need to Know in 2025

How to maintain a ratcheting brake line wrench?

Proper tool maintenance ensures reliable performance while extending service life through demanding brake service applications.

Routine Cleaning Protocol: Brake fluid is highly corrosive to most tool finishes and can deteriorate ratcheting mechanisms over time. Clean tools immediately after brake service using brake cleaner or isopropyl alcohol. Pay special attention to ratcheting mechanism areas where brake fluid contamination causes binding.

Lubrication Requirements: Light machine oil applied to ratcheting pawls maintains smooth operation. Avoid heavy greases that attract contamination in brake service environments. Quality tools benefit from monthly lubrication during regular use.

Common Problems and Solutions:

- Ratcheting mechanism binding: Usually caused by brake fluid contamination—clean thoroughly and re-lubricate

- Opening wear: Excessive use on damaged fittings causes opening enlargement—replace when precision is lost

- Handle looseness: Repeated shock loads can loosen handle assemblies—tighten or replace as needed

Replacement Indicators: Replace brake line wrenches when openings show visible wear, ratcheting mechanisms bind consistently, or precision fit on brake fittings becomes loose. Worn tools risk expensive brake component damage.

Do you know Who Invented the Allen Wrench?

Conclusion

Selecting the best ratcheting brake line wrench for 2025 requires balancing performance requirements, usage frequency, and budget considerations while prioritizing the safety that quality brake tools provide.

For Professional Brake Service: The IronCube Brake Line Wrench Set at $24-29 delivers professional capability with complete size coverage and reliable performance. The combination of quality construction, practical sizing, and accessible pricing makes this set ideal for both commercial shops and serious DIY mechanics.

For Maximum Professional Performance: Snap-on brake line wrenches ($45-75 each) provide ultimate precision and reliability for high-volume commercial brake service. The premium investment delivers exceptional performance for professionals whose livelihoods depend on tool reliability.

For Budget-Conscious Users: DURATECH and Anbull sets ($20-45) offer adequate performance for occasional brake maintenance while maintaining safety standards appropriate for DIY brake service.

Critical Safety Reminder: Brake system maintenance directly impacts vehicle safety. Quality tools contribute to proper brake service by enabling precise, controlled brake line connections. Never compromise on brake tool quality where safety is concerned.

Ready to upgrade your brake service capabilities? The IronCube Brake Line Wrench Set provides professional-grade performance at an accessible price, delivering the precision and reliability essential for safe brake system maintenance.