Whether you’re a professional mechanic or a weekend DIY enthusiast, understanding what a ratchet wrench is and how to effectively use a ratchet wrench set can dramatically improve your work efficiency and precision. From automotive repairs to home improvement projects, these versatile tools have become indispensable in countless applications. In this comprehensive guide, we’ll explore everything you need to know about ratcheting wrenches, from their fascinating history to practical usage techniques that will transform your approach to fastening tasks.

What is a Ratchet Wrench? Understanding the Fundamentals

A ratcheting wrench, also known as a ratchet handle or socket wrench, is a mechanical hand tool designed for tightening and loosening bolts, nuts, and other threaded fasteners. The defining characteristic that answers what is a ratchet wrench lies in its ingenious internal mechanism—a gear system that allows continuous rotation in one direction while preventing backward movement, eliminating the need to repeatedly lift and reposition the tool.

When exploring what is a ratchet used for, the applications are remarkably diverse. The tool’s primary function revolves around its ability to apply torque efficiently in confined spaces where a traditional wrench would require multiple repositioning cycles. This makes it invaluable for automotive work, machinery maintenance, construction projects, and precision assembly tasks.

The Evolution: When Was the Ratchet Invented?

The ratchet mechanism has ancient origins, but the modern ratcheting wrench as we know it today was refined in the early 20th century. When was the ratchet invented specifically for hand tools traces back to innovations in the 1920s and 1930s, when manufacturers began incorporating pawl-and-gear systems into socket wrenches. This revolutionary design eliminated the inefficiency of traditional wrenches in tight spaces and became a cornerstone of modern tool technology.

Understanding Drive Ratchets and Socket Systems

What is a drive ratchet refers to the square-shaped drive mechanism that connects the ratchet handle to interchangeable sockets. The most common drive sizes include:

- 1/4-inch drive: Ideal for small fasteners and precision work

- 3/8-inch drive: Perfect for medium-duty automotive and general applications

- 1/2-inch drive: Designed for heavy-duty applications and larger fasteners

- 3/4-inch drive: Industrial applications requiring high torque

- 1-inch drive: Heavy machinery and specialized industrial uses

How Ratchet Wrench Sets Work: The Mechanical Marvel

Internal Mechanism Breakdown

The genius behind ratchet wrench use lies in its sophisticated internal components:

Pawl System: A spring-loaded pawl engages with gear teeth inside the ratchet head, allowing rotation in one direction while locking against reverse motion.

Reversing Switch: Most quality ratchet wrench sets feature a directional switch that changes which direction allows free rotation, enabling both tightening and loosening operations.

Ball-Lock Socket Retention: A spring-loaded ball bearing securely holds sockets in place while allowing easy removal when needed.

Advantages Over Traditional Wrenches

When you use ratchet wrench tools instead of conventional wrenches, several key benefits emerge:

- Continuous Operation: No need to lift and reposition the tool repeatedly

- Space Efficiency: Works effectively in confined areas with limited swing radius

- Speed Enhancement: Dramatically reduces time required for repetitive fastening tasks

- Reduced Fatigue: Less physical strain during extended use periods

- Precision Control: Better torque application and fastener control

Comprehensive Applications: Ratchet Wrench Use Across Industries

Automotive and Transportation

Ratchet wrench sets dominate automotive applications where space constraints and efficiency demands are paramount:

- Engine Maintenance: Accessing hard-to-reach bolts in crowded engine compartments

- Brake System Service: Precise fastener control for safety-critical components

- Suspension Work: Managing multiple fasteners efficiently during repairs

- Oil Changes: Quick and clean drain plug and filter housing operations

Construction and Building Trades

Professional contractors rely on ratchet wrench use for:

- Steel Framework: Securing structural bolts in multi-story construction

- HVAC Installation: Connecting ductwork and equipment in tight spaces

- Electrical Panel Work: Precise torque application for electrical connections

- Plumbing Systems: Fitting connections where conventional tools cannot reach

Manufacturing and Assembly

Industrial applications showcase advanced ratchet wrench set capabilities:

- Production Line Assembly: Consistent torque application for quality control

- Machinery Maintenance: Accessing internal components during scheduled service

- Precision Instrument Assembly: Delicate fastener handling requiring controlled force

- Quality Assurance: Ensuring proper fastener tension across multiple production units

Home Workshop and DIY Projects

For enthusiasts wondering what is a ratchet used for in home applications:

- Furniture Assembly: Efficient construction of complex furniture pieces

- Appliance Repair: Accessing internal fasteners safely and effectively

- Automotive Maintenance: Basic car care and minor repair projects

- Home Improvement: General construction and renovation tasks

Selecting the Perfect Ratchet Wrench Set: Professional Guidance

Essential Set Components

A comprehensive ratchet wrench set should include:

Multiple Drive Sizes: 1/4″, 3/8″, and 1/2″ drives cover most applications Socket Variety: Both metric and SAE measurements in standard and deep configurations Extension Bars: Various lengths for reaching recessed fasteners Universal Joints: Enabling access at awkward angles Specialized Sockets: Spark plug, oxygen sensor, and other application-specific designs

Quality Indicators and Features

When evaluating what is a ratchet wrench of professional quality, consider:

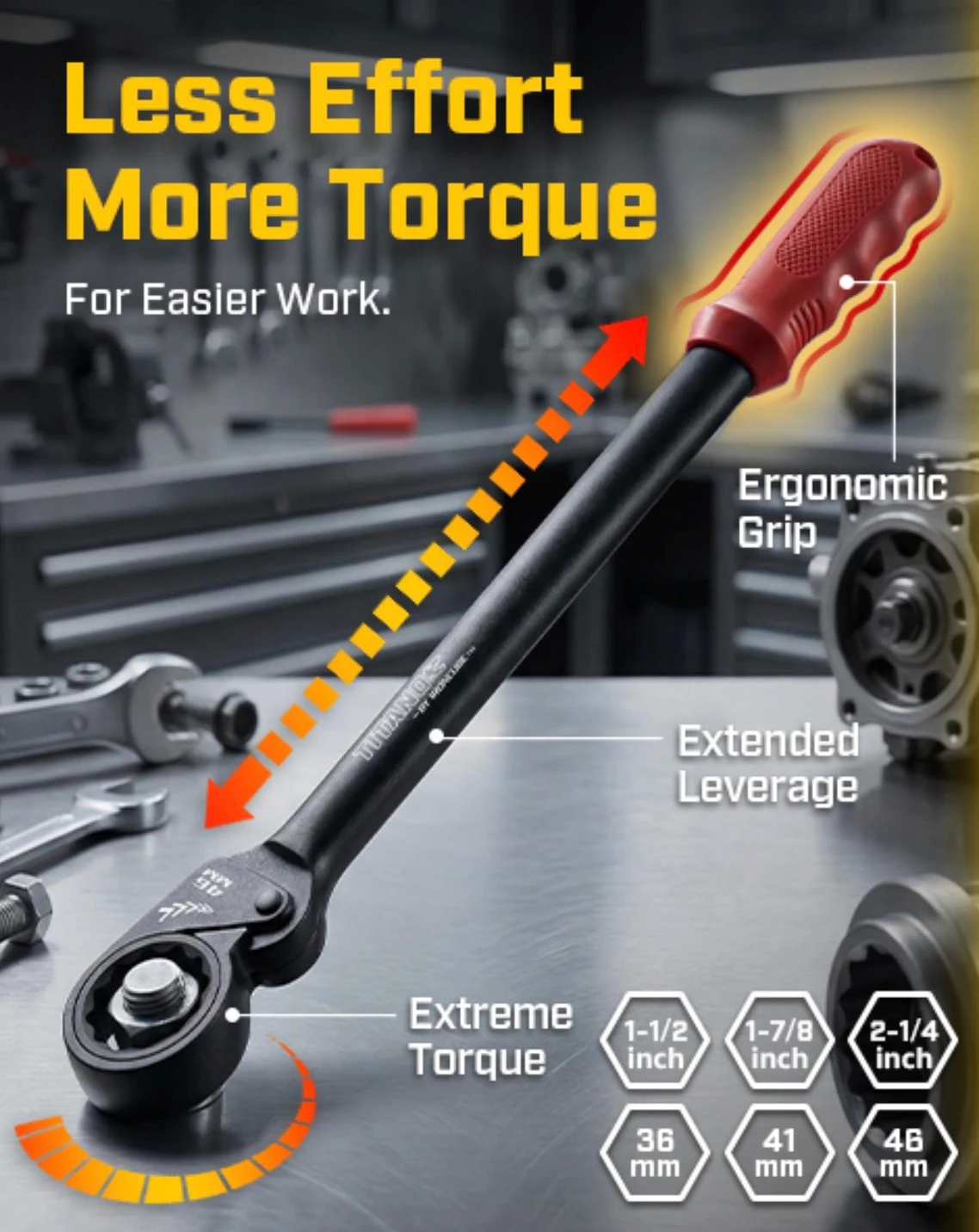

Tooth Count: Higher tooth counts (72+ teeth) provide finer control and smaller swing arcs Material Construction: Chrome vanadium steel offers optimal strength and corrosion resistance Comfort Grip: Ergonomic handles reduce fatigue during extended use Quick-Release Mechanism: Efficient socket changes improve workflow productivity Durability Rating: Professional-grade tools often include lifetime warranties

Professional vs. DIY Applications

Professional Requirements:

- Heavy-duty construction for daily use

- Comprehensive socket selection

- Precision torque capabilities

- Rapid socket changing systems

DIY Considerations:

- Cost-effective basic sets

- Essential socket sizes only

- Comfortable ergonomics for occasional use

- Storage organization systems

How to Maintenance and Longevity the Ratchest Wrench?

Professional ratchet wrench use requires proper maintenance.

Regular Cleaning: Remove debris from gear mechanisms and socket drives

Lubrication Schedule: Apply appropriate lubricants to moving parts periodically

Storage Protection: Organize tools to prevent damage and maintain precision

Inspection Routine: Check for wear patterns and replace components as needed. Safety glasses and gloves during intensive use

Torque Limitations: Respect tool specifications to prevent failure or injury

Proper Positioning: Maintain stable footing and balanced stance during operation

Tool Inspection: Regular examination for cracks, wear, or mechanical issues.

Conclusion: Mastering the Ratcheting Wrench

Understanding what is a ratcheting wrench extends far beyond its basic definition as a mechanical tool. These sophisticated instruments represent decades of engineering refinement designed to solve real-world fastening challenges efficiently and safely. Whether you’re assembling a ratchet wrench set for professional use or seeking to understand ratchet wrench use for DIY projects, the key lies in appreciating both the mechanical elegance and practical versatility these tools offer.

From their historical development answering when was the ratchet invented to modern innovations in what is a drive ratchet technology, ratcheting wrenches continue evolving to meet changing industrial demands. By mastering proper techniques for use ratchet wrench applications and understanding what is a ratchet used for across different industries, you’ll unlock the full potential of these remarkable tools.

The investment in quality ratchet wrench sets pays dividends through improved efficiency, reduced physical strain, and enhanced precision across countless applications. As you develop expertise in ratchet wrench use, you’ll discover new applications and techniques that further demonstrate why these tools have become essential components of any serious toolkit.