When a fastener is buried behind brake lines, steering components, or frame rails, a standard wrench often just won’t fit. The 16-Piece Thin Wrench Set solves that problem with a 3 mm extra-slim profile that reaches where bulky tools cannot, while still delivering the strength needed for real automotive and machinery work. This guide explains how a professional thin wrench set works, where it shines, and how IRONCUBE® WORKS turns a slim profile into a reliable, long-term tool investment.

This is where a specialized tool becomes a necessity, not a luxury. For the serious professional or committed enthusiast, having the right gear can make the difference between a quick fix and hours of struggle. A 16-Piece Thin Wrench Set, like the one meticulously crafted by IRONCUBE® WORKS, is the precise solution to conquer those incredibly restrictive spaces. This guide dives deep into why this super thin wrench set is an indispensable addition to your professional toolkit.

What Is a 16-Piece Thin Wrench Set?

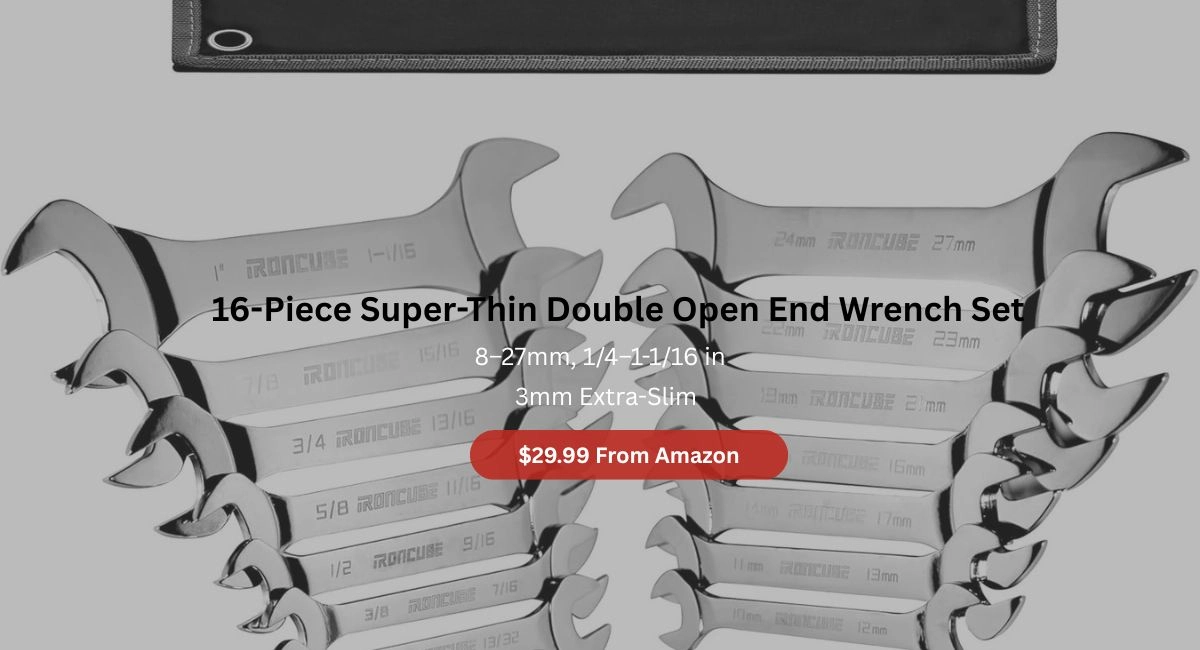

A 16-Piece Thin Wrench Set is a double open-end wrench kit designed with an ultra slim, around 3 mm thick body so it can access fasteners in tight or obstructed spaces. It combines both metric and SAE sizes in one roll-up pouch, which helps technicians carry a compact but complete setup for mixed vehicles and equipment.

Unlike bulky combination wrenches, this super-thin wrench set uses a narrow, polished chrome or alloy steel construction that slides into gaps between lines, brackets, and housings. A professional thin wrench set like this often covers most common automotive, motorcycle, and machinery sizes, so you do not need separate thin tools for each standard.

Why Thin Wrenches Matter in Automotive Repair

Many fasteners on modern vehicles are hidden behind hoses, fuel lines, or suspension components, where a standard wrench or socket cannot swing. A 16-Piece Thin Wrench Set helps in three key ways:

The 3 mm ultra slim body reaches narrow gaps around brake fittings, fuel connections, and steering racks.

The open-end profile grips the nut without needing extra clearance for a socket head.

Having both metric thin wrench set sizes and SAE thin wrench set sizes avoids switching tool kits between vehicles.

For a workshop handling passenger cars, motorcycles, and light trucks, this flexibility reduces time spent hunting for “that one thin wrench” and helps avoid rounding nuts with improper tools.

What Makes a Thin Wrench Set Different?

The profile thickness separates thin wrenches from standard tools. Traditional open-end wrenches measure 8-12mm thick. A super thin wrench set measures just 3mm at the head. This 70% reduction matters when you’re working around brake lines, suspension components, or motorcycle engine cases.

Think about modern vehicles. Engineers pack more components into smaller spaces every year. Fuel injectors sit behind brackets. Sensors hide beneath wiring harnesses. Hydraulic fittings nestle against frame rails. Your standard wrench hits obstacles before reaching the fastener. A thin wrench slides right past.

The engineering behind this design requires precision. IRONCUBE® uses CNC machining centers to maintain exact tolerances. Each wrench head gets milled to 3mm without compromising strength. Heat-treated alloy steel provides the necessary durability. Mirror chrome plating adds corrosion resistance.

Key Design Features

Chrome vanadium thin wrench construction offers superior strength-to-weight ratios. The alloy composition includes:

- Carbon for hardness and wear resistance

- Chromium for corrosion protection and surface durability

- Vanadium for grain refinement and increased toughness

- Manganese for improved hardenability

This metallurgy matters when you apply torque in confined spaces. The thin profile concentrates stress differently than thick wrenches. Proper heat treatment ensures the tool won’t flex, crack, or deform under normal working loads.

Complete Size Coverage: SAE and Metric Standards

A professional thin wrench set needs comprehensive coverage. The 16-piece configuration includes both measurement systems. You won’t switch between sets or make multiple trips to the toolbox.

SAE (Imperial) Sizes Included:

Each wrench features dual sizing—two different sizes on one tool. This doubles your options while reducing what you carry:

- 1/4″ × 9/32″

- 11/32″ × 13/32″

- 3/8″ × 7/16″

- 1/2″ × 9/16″

- 5/8″ × 11/16″

- 3/4″ × 13/16″

- 7/8″ × 15/16″

- 1″ × 1-1/16″

Metric Sizes Included:

The metric selection covers common automotive and machinery fasteners:

8mm, 9mm, 10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 19mm, 21mm, 22mm, 23mm, 24mm, 27mm

This range handles most passenger vehicles, light trucks, motorcycles, and small equipment. The dual-end design means 16 physical wrenches provide 32 size options.

Size Conversion Reference Table

| Metric (mm) | SAE (Inches) | Common Applications |

|---|---|---|

| 8mm | 5/16″ | Small fasteners, motorcycles |

| 10mm | 3/8″ | Engine covers, accessories |

| 12mm | 1/2″ | Suspension, steering |

| 13mm | 1/2″ | Wheel components |

| 14mm | 9/16″ | Brake calipers, lines |

| 17mm | 11/16″ | Lug nuts (some vehicles) |

| 19mm | 3/4″ | Larger suspension bolts |

| 22mm | 7/8″ | Axle nuts, hubs |

Clear size stamping on each wrench prevents confusion. The numbers get stamped deep enough to remain readable after years of use. No squinting or guessing which size you’re holding.

When You Should Use a Super Thin Wrench Set

Automotive Repair

Perfect for hidden bolts under:

Brake boosters

Master cylinders

Transmission mounts

Fuel rails

AC compressor brackets

The thin wrench set for automotive repair shines because standard wrenches often hit firewall panels or hoses.

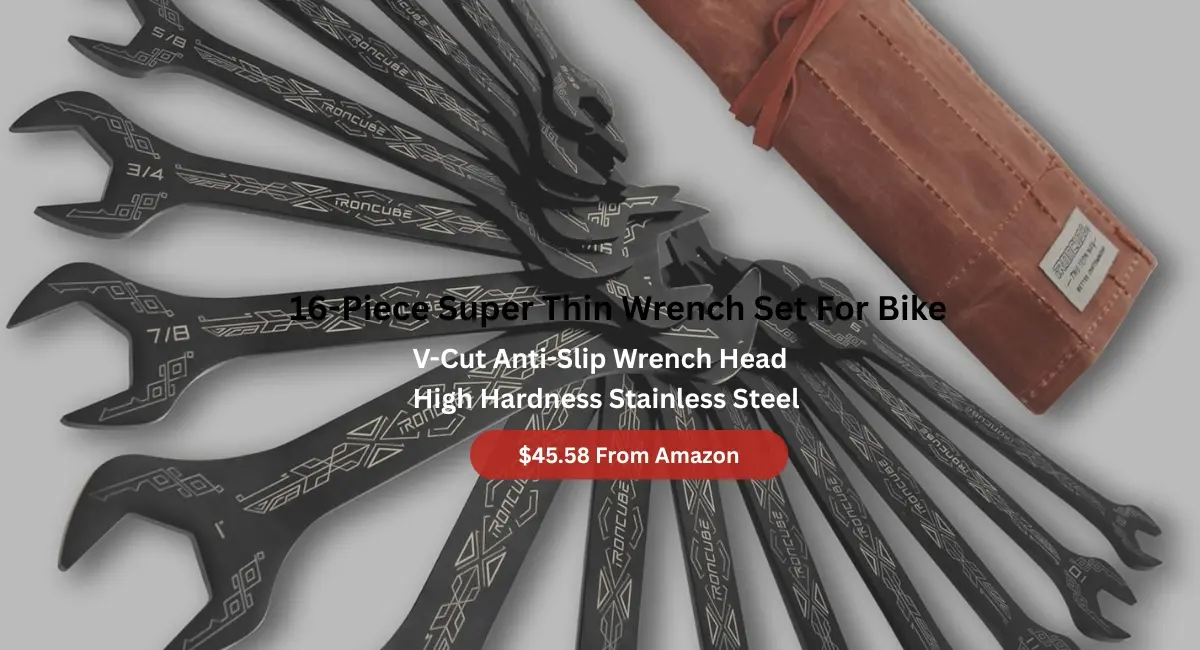

Motorcycle & Bicycle Maintenance

Compact engines = tiny clearances. Thin wrenches are ideal for:

Carburetor tuning

Brake adjustments

Suspension linkage

Handlebar clamp hardware

Machinery & Industrial Equipment

Precision equipment often includes:

Narrow tool clearances

Lock nuts positioned behind guards

Multiple tightening points in confined zones

A super thin wrench set provides safe access without removing surrounding components.

Real-World Applications Where Thin Wrenches Excel

Automotive Brake System Work

Brake line fittings present classic tight-access challenges. The lines run along frame rails, behind crossmembers, and through narrow brackets. Standard wrenches hit surrounding components before engaging the flare nut. A thin wrench set for automotive repair solves this immediately.

When bleeding brakes, you need secure fitment on bleeder screws. Many calipers position these screws in recessed areas. The thin profile reaches them without interference. The same applies to proportioning valves, combination valves, and master cylinder fittings.

Fuel System Maintenance

Modern fuel injection systems use high-pressure lines with specialized fittings. These connections often sit in engine valley areas or beneath intake manifolds. Accessing them requires tools that fit past wiring harnesses, vacuum lines, and other plumbing.

A metric thin wrench set handles most fuel system work. The sizes from 10mm through 17mm cover fuel rail connections, injector lines, and pressure regulator fittings. The chrome plating resists fuel and oil exposure.

Motorcycle and Small Engine Repair

Motorcycles pack significant complexity into compact spaces. Engine cases, carburetors, and electrical components all compete for limited real estate. Standard automotive wrenches simply don’t work.

The 14 piece super thin wrench (or 16-piece version) becomes essential for motorcycle work. Whether you’re adjusting valve clearances, removing carburetor jets, or accessing oil fittings, the slim profile makes jobs possible that would otherwise require extensive disassembly.

HVAC and Plumbing Installation

Professional installers face tight spaces regularly. HVAC units mount against walls with minimal clearance. Refrigerant line fittings hide behind brackets. Water supply connections nestle in corners.

The SAE thin wrench set handles plumbing fixtures, compression fittings, and valve packings. The dual sizing means carrying one compact roll pouch instead of multiple wrench sets.

Industrial Equipment Maintenance

Factory machinery, hydraulic systems, and processing equipment use thin-profile fasteners. Maintenance technicians need tools that access components without removing guards, panels, or adjacent assemblies.

A chrome vanadium thin wrench withstands industrial environments. The heat-treated steel handles repeated use. The corrosion-resistant finish survives exposure to cutting fluids, hydraulic oil, and cleaning chemicals.

Why Professionals Choose Our Best 16 Piece Thin Wrench Set

Since 2008, IRONCUBE® has built a formidable reputation as a manufacturer committed to high-quality hand tools. We’re not just a distributor; we are a manufacturer with our own factory, R&D capability, and stringent quality control processes—all rooted in our beginnings in Ningbo. This means that every tool, including our renowned 16-Piece Thin Wrench Set, is a direct result of continuous improvement and engineering expertise.

Simplify With Every Turn

The IRONCUBE® 16-Piece Slim Wrench Set is designed to make your work easier and more efficient. Each wrench features two sizes, allowing you to tackle multiple tasks without carrying extra tools. The set includes both SAE and Metric sizes, covering a wide range of applications. Standard sizes like 1/4″x9/32″, 3/8″x7/16″, and 1″x1-1/16″ ensure compatibility with common fasteners, while Metric sizes like 8mm, 10mm, and 17mm cater to international standards. This dual-size design reduces clutter in your toolbox and ensures you always have the right tool at hand. Whether you’re working on automotive repairs, machinery maintenance, or DIY projects, this set simplifies your workflow and saves valuable time.

Easily Reach Those Tricky Spots

The IRONCUBE® 16-Piece Super Thin Wrench Set is engineered for precision in tight spaces. With a sleek 3mm profile, these wrenches are 70% slimmer than standard tools, making them perfect for cramped engine bays, narrow brake lines, and awkward angles. Whether you’re repairing a car, motorcycle, or bicycle, this set ensures you can access fasteners effortlessly. The slim design not only enhances maneuverability but also prevents damage to delicate components. Professionals and DIY enthusiasts alike will appreciate the ease of use and reliability this set offers. It’s a must-have for anyone who values precision and efficiency in their toolkit.

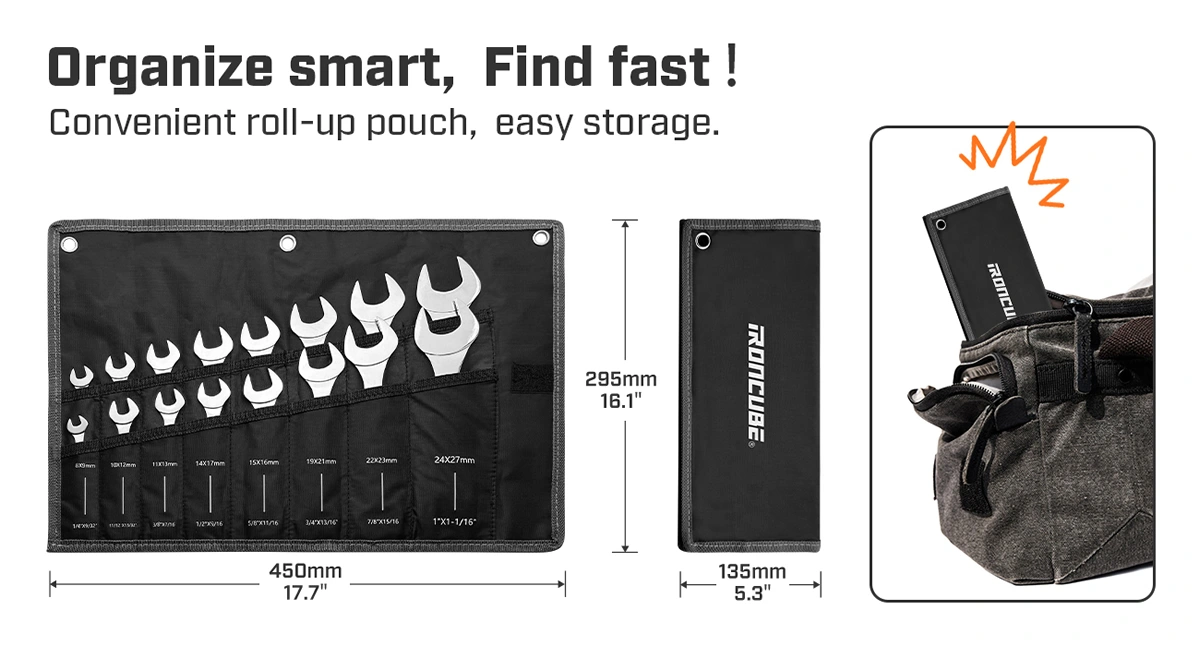

Organize Smart, Find Fast

The IRONCUBE® Super Thin Wrench Set comes with a durable tool bag designed for portability and organization. This roll-up pouch features clear size labels and secure lanyards, making it easy to store and transport your tools. Whether you’re on the go, working in the garage, or tackling roadside repairs, this bag keeps your wrenches neatly organized and ready for action. It’s also a thoughtful gift for anyone who values order and efficiency in their workspace. With this set, you’ll never waste time searching for the right wrench again.

Precisely Fits Nut Sizes

The IRONCUBE® Super Thin Wrench Set is engineered for precision and performance. Each wrench is designed with exact dimensions to ensure a perfect fit on nuts, allowing for greater torque without slippage. The open-end design provides a superior grip while protecting nuts from wear and tear. This ensures safer and more secure operations, whether you’re working on bikes, cars, or machinery. Professionals and DIY enthusiasts alike will appreciate the reliability and durability of these wrenches. With IRONCUBE®, you’re not just buying tools—you’re investing in precision and peace of mind.

IRONCUBE® Manufacturing Advantage

Since its establishment in 2008, IRONCUBE® has carved out a niche in the hand tool industry by focusing on precision, quality, and innovation. Based in Ningbo, the company operates its own state-of-the-art manufacturing facilities, giving it full control over every aspect of production. This direct oversight ensures that every tool meets the highest standards of durability and performance.

Direct Manufacturing Benefits

- Factory Control: By managing production in-house, IRONCUBE® guarantees consistent quality. There’s no reliance on third-party manufacturers, eliminating the risk of shortcuts or compromises in the manufacturing process.

- R&D Capability: The company’s internal research and development team continuously improves products based on customer feedback and industry trends. This commitment to innovation ensures that IRONCUBE® tools stay ahead of the curve.

- Custom Solutions: Whether you’re looking for OEM orders or customized designs, IRONCUBE® offers flexibility to meet specific needs. From private label products to unique size ranges, the manufacturing infrastructure supports tailored solutions.

- Quality Assurance: Every stage of production undergoes rigorous quality checks. Direct oversight allows for immediate identification and correction of any issues, ensuring that only flawless tools reach customers.

Global Market Experience

IRONCUBE® serves both European and American markets, leveraging its international experience to understand diverse standards, preferences, and regulatory requirements. This global perspective ensures that products meet the expectations of customers worldwide. Additionally, the company collaborates with other high-end manufacturers when necessary, expanding its product range while maintaining unwavering quality across all offerings.

For wholesale buyers, distributors, or businesses seeking reliable tool suppliers, partnering with IRONCUBE® offers distinct advantages. By working directly with the manufacturer, you gain access to superior products, customized solutions, and unparalleled support—all from a trusted source with over a decade of expertise.

Conclusion

IRONCUBE® manufactures these sets in-house, controlling every aspect of production from raw materials to final finishing. Since 2008, we’ve built our reputation on delivering reliable tools that professionals trust.

Our 16-Piece Thin Wrench Set includes both SAE and metric sizing with a durable organizing pouch. The 3mm profile reaches spaces standard wrenches can’t access. Chrome vanadium construction ensures strength and longevity.

Looking for comprehensive tool solutions? Explore our complete range of hand tools, including screwdrivers and combination wrench sets.

For bulk orders or custom requirements, we offer OEM capabilities and customized designs meeting your exact specifications. As the manufacturer, we provide direct pricing without middleman markups.

Visit our Amazon store for convenient ordering, or contact us directly to discuss wholesale opportunities, private labeling, or specific application requirements.

Quality tools make quality work possible. Get yours from the factory that makes them.

Check out our YouTube channel for product demonstrations and usage tips.

FAQs

Q: Can thin wrenches handle the same torque as standard wrenches?

A: When manufactured from proper materials with correct heat treatment, quality thin wrenches handle normal working torques safely. IRONCUBE® uses chrome vanadium alloy steel with controlled heat treatment to ensure adequate strength despite the slim profile.

Q: What’s the difference between a 14-piece and a 16-piece thin wrench set?

A: The 16-piece configuration typically includes both SAE and metric sizing, while 14-piece sets often cover one measurement system comprehensively. For professional use or working on various vehicle types, the 16-piece set provides better coverage.

Q: How do I verify I’m getting genuine chrome vanadium steel construction?

A: Look for manufacturers with documented quality control processes and relevant certifications. IRONCUBE® operates its own CNC machining centers and forging workshops, maintaining direct control over materials and production. Products should clearly state alloy composition and heat treatment specifications.

Q: Are thin wrench sets suitable for bulk procurement for professional shops?

A: Absolutely. Many shops equip each service bay or technician with a dedicated thin wrench set. The organization’s benefits and time savings justify the investment. As a manufacturer, IRONCUBE® welcomes OEM orders and offers customization options for bulk buyers. Direct factory ordering often provides better pricing than retail purchases while ensuring consistent quality across all units.

Q: What warranty or support comes with professional-grade thin wrench sets?

A: Quality manufacturers stand behind their products with hassle-free warranty coverage. IRONCUBE® backs each wrench set with support addressing any defects or performance issues. For bulk orders or ongoing supply agreements, manufacturers typically provide additional support and replacement policies.