The IRONCUBE Reversible Ratcheting Wrench Set isn’t just another toolkit; it’s a performance-driven innovation designed to elevate your workflow.

Built with industrial-grade materials, ergonomic handles, and reversible mechanisms, this wrench set offers smooth and rapid operation in even the tightest spaces. Whether you’re fixing automotive parts, assembling machinery, or tackling DIY home projects, IRONCUBE’s Ratcheting Wrench Set ensures your work is efficient, accurate, and effortless.

Check out IRONCUBE Works to explore the full range of workshop tools and accessories.

What is a Ratcheting Wrench Set?

A ratcheting wrench set is a collection of wrenches that feature a ratcheting mechanism, allowing users to turn fasteners without removing the tool from the bolt or nut. This mechanism is particularly useful in confined spaces where traditional wrenches would require constant repositioning.

The IRONCUBE Ratcheting Wrench Set is engineered with precision and durability in mind. It includes a range of sizes to handle various tasks, from automotive repairs to industrial maintenance. The reversible feature allows users to switch between tightening and loosening with ease, making it a versatile addition to any toolkit.

For a deeper understanding of how these tools work, check out our detailed guide on the Principle of Ratcheting Wrench.

Why IRONCUBE Stands Out

IRONCUBE isn’t just another tool manufacturer — it’s a brand built on engineering precision and user-centric innovation. The IRONCUBE Ratcheting Wrench Set is crafted for mechanics who demand strength and finesse in one package.

Here’s what makes it stand out:

Reversible Function: The quick-switch lever lets you change direction without removing the wrench, boosting productivity.

72-Tooth Gear Mechanism: Provides a 5° swing arc for working in tight spots.

Chrome Vanadium Steel Build: Ensures durability, corrosion resistance, and long tool life.

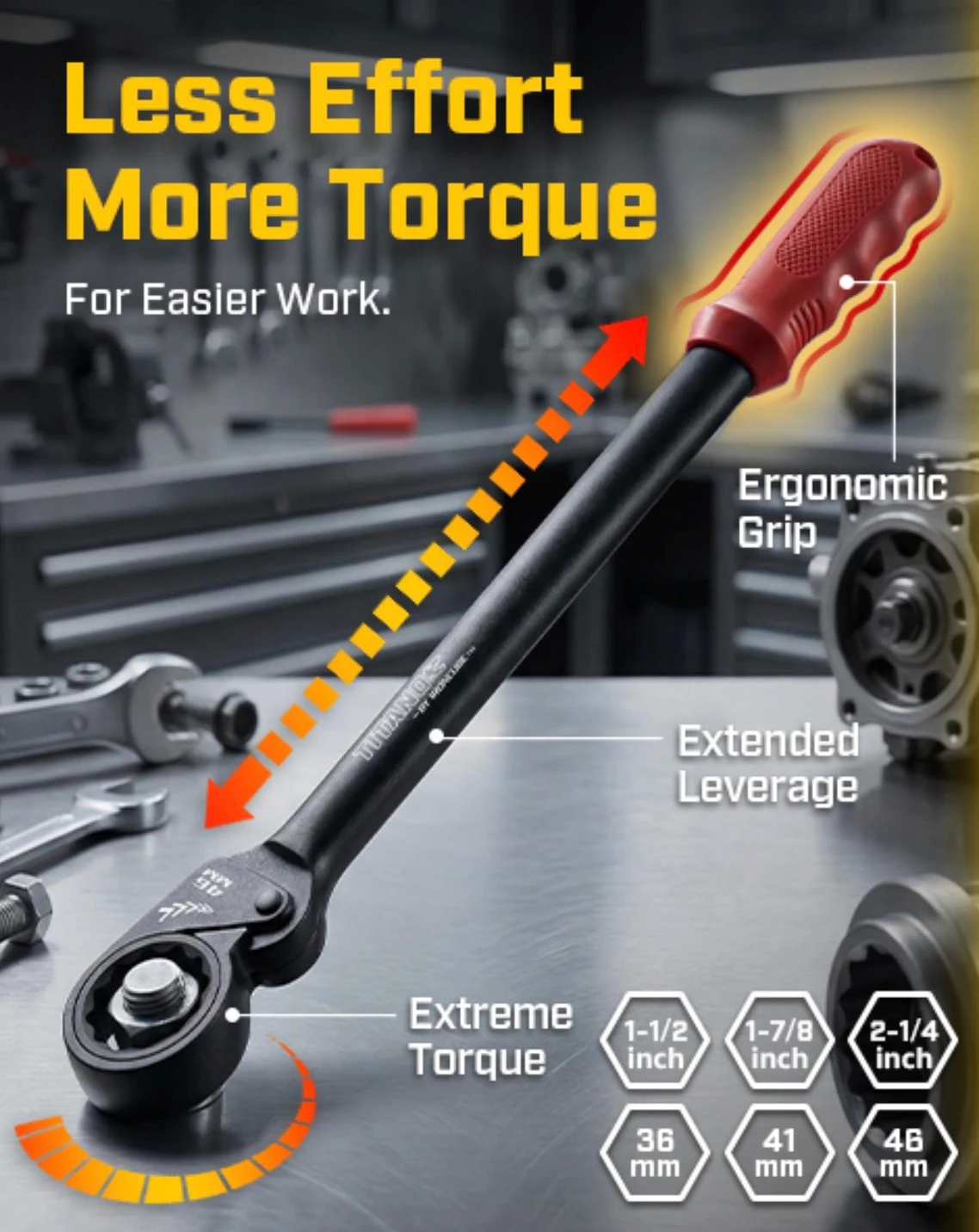

Ergonomic Grip: Designed to minimize fatigue during extended use.

Mirror Polish Finish: Offers sleek looks and easy cleaning.

Want to explore the professional-grade sets? Visit Best IRONCUBE 12pcs Ratcheting Wrench Set.

Why Professional Workshops Need Quality Ratcheting Wrench Sets

Professional workshops operate under constant pressure to maximize efficiency while maintaining quality standards. Every minute saved on a repair translates directly to improved profitability and customer satisfaction. This economic reality makes investing in high-quality ratcheting wrench sets not just a preference but a business necessity.

A quality ratcheting wrench set transforms this equation entirely. The technician can maintain continuous contact with the fastener, working the wrench back and forth in a confined space without the constant cycle of removal and repositioning. This efficiency gain can cut job completion times by 30 to 50 percent for tasks involving numerous fasteners in tight spaces.

Beyond time savings, professional-grade ratcheting wrenches reduce physical fatigue during extended work sessions. The continuous motion pattern is less taxing on hands, wrists, and shoulders compared to the repetitive gripping, releasing, and repositioning required with standard wrenches. For technicians working eight-hour shifts or longer, this ergonomic advantage significantly impacts comfort and reduces the risk of repetitive strain injuries.

Quality matters immensely in professional settings where tools face daily abuse. Inexpensive ratcheting wrenches might save money initially, but they often fail prematurely when subjected to professional workloads. The internal ratcheting mechanism is particularly vulnerable—cheap pawls can strip, springs can weaken, and the precise tolerances necessary for smooth operation deteriorate quickly with hard use.

IRONCUBE’s commitment to professional-grade quality ensures their ratcheting wrench sets meet the demanding standards of commercial workshops. Their tools undergo rigorous testing protocols that simulate years of professional use, ensuring the ratcheting mechanisms maintain smooth operation and reliable torque transfer even after thousands of cycles.

Why Choose the IRONCUBE Ratcheting Wrench Set?

Superior Build Quality

The IRONCUBE Ratcheting Wrench Set is crafted from high-grade chrome vanadium steel, ensuring exceptional strength and resistance to wear and tear. This makes it ideal for heavy-duty applications in professional workshops.

Ergonomic Design

Each wrench in the set features an ergonomic handle designed to reduce hand fatigue during prolonged use. The non-slip grip ensures maximum control, even in oily or greasy conditions.

Reversible Mechanism

The reversible ratcheting mechanism allows for quick and easy switching between tightening and loosening modes. This feature saves time and effort, especially when working in tight spaces.

Comprehensive Size Range

The set includes a wide range of sizes, making it suitable for various applications. Whether you’re working on a car, motorcycle, or industrial machinery, the IRONCUBE Ratcheting Wrench Set has you covered.

For more details on the size options, visit our Metric Ratcheting Wrench Sets Professional Guide.

Detailed Specifications: Inside the IRONCUBE Wrench Set

The IRONCUBE Reversible Ratcheting Wrench Set is available in both metric and SAE sizes, making it versatile for global users. Below is a detailed overview:

| Size (Metric) | Size (SAE) | Application |

|---|---|---|

| 8 mm | 5/16 inch | Light automotive work |

| 10 mm | 3/8 inch | General repairs |

| 12 mm | 7/16 inch | Engine assembly |

| 13 mm | 1/2 inch | Heavy-duty mechanical tasks |

| 14 mm | 9/16 inch | Machinery setups |

| 17 mm | 11/16 inch | Suspension work |

| 19 mm | 3/4 inch | Industrial maintenance |

You can check more details on Metric Ratcheting Wrench Sets – Professional Guide.

Conversion Chart: Metric to SAE Equivalents

Understanding the relationship between metric and SAE fastener sizes helps when you need to use one system’s tools on another system’s fasteners. While exact equivalents rarely exist, these near-matches work in many situations:

| Metric Size | Nearest SAE Equivalent | Difference | Usage Notes |

|---|---|---|---|

| 6mm | 1/4 inch | +0.35mm | SAE slightly larger, generally acceptable |

| 7mm | 9/32 inch | -0.17mm | Very close match, interchangeable in most cases |

| 8mm | 5/16 inch | +0.13mm | SAE slightly larger, usually works |

| 9mm | 11/32 inch | -0.21mm | Metric slightly larger, use caution |

| 10mm | 3/8 inch | +0.53mm | SAE significantly larger, may slip on metric |

| 11mm | 7/16 inch | +0.18mm | SAE slightly larger, generally works |

| 12mm | 15/32 inch | -0.12mm | Very close match, typically interchangeable |

| 13mm | 1/2 inch | +0.30mm | SAE slightly larger, often acceptable |

| 14mm | 9/16 inch | +0.09mm | Extremely close match, freely interchangeable |

| 15mm | 19/32 inch | -0.08mm | Very close match, typically interchangeable |

| 16mm | 5/8 inch | +0.88mm | SAE noticeably larger, use with caution |

| 17mm | 11/16 inch | +0.48mm | SAE moderately larger, may work |

| 18mm | 23/32 inch | -0.84mm | Metric larger, not recommended to substitute |

| 19mm | 3/4 inch | +0.05mm | Extremely close match, effectively identical |

| 20mm | 25/32 inch | -0.12mm | Very close match, usually interchangeable |

| 21mm | 13/16 inch | +0.78mm | SAE larger; use cautiously |

| 22mm | 7/8 inch | +0.25mm | SAE slightly larger, often works |

| 24mm | 15/16 inch | -0.12mm | Very close match, typically interchangeable |

Important considerations when using these conversions: Always prefer the correct measurement system when available. Cross-system substitution works better for removing fasteners than installing them, where proper torque specifications matter. Worn or damaged fasteners are much more likely to round off when using approximate size matches. In critical applications involving torque specifications or safety-critical fasteners, always use the correctly-sized tool.

For full product availability, visit Ratcheting Combo Sets Amazon SHOP.

Key Features to Look for in a Ratcheting Wrench Set

Selecting the right ratcheting wrench set requires understanding several critical features that separate professional-grade tools from consumer-level alternatives. These characteristics directly impact performance, durability, and long-term value.

Tooth Count and Swing Arc

The number of teeth in the ratcheting mechanism fundamentally determines how small a swing arc the wrench requires to advance the fastener. This specification typically ranges from 72 teeth to 120 teeth in modern designs, with some premium models offering even higher tooth counts.

Higher tooth counts do come with tradeoffs, however. More teeth mean each individual tooth is smaller and potentially weaker. Quality manufacturers address this through superior metallurgy and heat treatment processes, but there’s still a balance to strike between fine indexing and structural strength. For heavy-duty applications involving high torque, a 72 or 90-tooth design might actually prove more durable than ultra-fine 120-tooth alternatives.

Material Quality and Heat Treatment

The materials and manufacturing processes used in constructing ratcheting wrenches directly determine their longevity and reliability. Professional-grade wrenches should be forged from high-grade chrome vanadium steel, which offers an excellent balance of strength, durability, and resistance to deformation under load.

Chrome vanadium steel contains chromium for corrosion resistance and hardness, plus vanadium for strength and wear resistance. After forging, quality wrenches undergo controlled heat treatment processes that harden the working surfaces while maintaining some toughness in the body to prevent brittle fractures.

The finish applied to the wrench serves both aesthetic and functional purposes. Chrome plating provides corrosion protection while creating a smooth surface that resists dirt accumulation and cleans easily. Some manufacturers apply additional coatings or treatments to enhance corrosion resistance in harsh environments.

Reversing Mechanism Design

The method used to reverse the ratcheting direction varies among manufacturers and significantly impacts usability. The most common designs include lever switches, flip mechanisms, and button-activated systems, each with distinct advantages and considerations.

Lever-style reversing switches typically protrude slightly from the wrench head and can be flipped with a thumb while holding the wrench. This design allows quick, one-handed direction changes without removing the tool from the fastener. However, protruding levers can occasionally catch on surrounding components in extremely tight spaces.

Flush-mount designs eliminate the protrusion issue by integrating the reversing mechanism into the wrench head profile. These require slightly more deliberate action to change direction but offer better clearance in confined areas. The trade-off between convenience and clearance depends on your specific application priorities.

Box End Configuration

The closed-end design of ratcheting wrenches affects both fastener engagement and access in tight spaces. Most quality ratcheting wrenches feature a 12-point box end configuration that allows the wrench to engage a hex fastener at 30-degree intervals rather than requiring precise 60-degree alignment like 6-point designs.

12-point designs excel in situations where you can’t fully rotate the wrench to achieve perfect alignment with a 6-point configuration. However, they distribute torque across smaller contact points on the fastener corners, which can round off damaged or corroded fasteners more easily than 6-point designs that engage the fastener flats.

Some premium ratcheting wrench sets include both 12-point and 6-point configurations for different applications. The 6-point versions provide maximum grip on stubborn fasteners, while 12-point versions offer superior access in restricted spaces. Having both options available expands your capability to handle diverse situations effectively.

Open-End Design

The open end of combination-style ratcheting wrenches provides quick fastener access when you can’t slip a closed box end over the fastener head. Quality designs ensure the open end jaws are precisely sized and aligned to minimize slippage and fastener damage.

Professional-grade wrenches feature open ends with precise tolerance matching to fastener sizes, maximizing surface contact and torque transfer. The jaw opening should allow easy fastener engagement while maintaining minimal play once positioned. Excessive tolerance creates wobble that can round fastener corners and reduces the effective torque you can safely apply.

The angle offset between the open end and the handle also matters for clearance and leverage. Most professional wrenches offset the open end by 15 degrees, which provides a good balance between access and knuckle clearance when working near obstacles.

IRONCUBE Ratcheting Wrench Set: Professional Quality Standards

IRONCUBE has established itself as a trusted name in professional hand tools by consistently delivering products that meet the rigorous demands of commercial workshops. Their ratcheting wrench sets embody a commitment to quality, durability, and user-focused design that working professionals appreciate.

Manufacturing excellence begins with material selection, and IRONCUBE sources premium chrome vanadium steel for all their wrench production. This steel undergoes proprietary heat treatment processes that achieve optimal hardness in the working surfaces while maintaining sufficient toughness in the body to prevent catastrophic failure under shock loads.

The ratcheting mechanisms in IRONCUBE wrenches feature precisely machined gear teeth and hardened pawls that maintain engagement integrity through thousands of work cycles. Unlike cheaper alternatives where the pawls may skip or fail to engage reliably after moderate use, IRONCUBE’s mechanism design ensures consistent performance throughout the tool’s service life.

Professional finishes applied to IRONCUBE wrenches serve multiple purposes beyond aesthetics. The high-polish chrome plating provides excellent corrosion resistance while creating a surface that sheds dirt and oil easily. This makes cleanup simple at the end of each work shift and helps maintain the tools in pristine condition even with daily professional use.

Sizing accuracy is another area where IRONCUBE demonstrates professional commitment. Their wrenches are manufactured to exact dimensional specifications, ensuring proper fit on both metric and SAE fasteners without excessive play. This precision prevents the frustrating slippage and fastener rounding that occurs with loosely-toleranced tools.

The reversing mechanisms on IRONCUBE ratcheting wrenches strike an excellent balance between ease of use and durability. The levers provide positive tactile feedback when switching directions, eliminating any uncertainty about the current setting. The mechanisms are designed to resist accidental direction changes while remaining easy to operate intentionally.

Ergonomic considerations influence every aspect of IRONCUBE’s wrench design. The handle proportions provide comfortable grip options for various hand sizes, while the overall weight distribution creates natural balance that reduces fatigue during extended use. These subtle design elements distinguish tools built for professional daily use from casual consumer alternatives.

The Reversible Advantage

The reversible mechanism is where IRONCUBE takes a leap ahead. Traditional ratchets require flipping the wrench to reverse direction, but IRONCUBE integrates a directional lever. This allows seamless transitions between tightening and loosening — an invaluable feature for time-sensitive projects.

This reversible function reduces tool wear, increases efficiency, and makes operations smoother, especially in tight engine compartments or industrial equipment.

Durability and Build Quality

Crafted from Chrome Vanadium (Cr-V) Steel, IRONCUBE wrenches are engineered to resist high torque and corrosion. Each wrench undergoes heat treatment and mirror polishing, ensuring superior strength and an attractive finish.

The set is also ANSI & DIN standard certified, making it a trustworthy companion for professionals who value quality and precision.

For those who prefer custom engravings or branding, IRONCUBE also offers customized tool sets at IRONCUBE Customized Tools.

Ease of Use and Ergonomic Design

IRONCUBE tools are made with user comfort in mind. The handles feature a non-slip grip, and the ratcheting action feels incredibly smooth. This ergonomic advantage reduces strain during extended work hours, ensuring better control and accuracy.

For visual learners, check out IRONCUBE Tools’ YouTube Channel for tool demonstrations and usage tutorials.

Where to Buy IRONCUBE Ratcheting Wrenches

You can grab your IRONCUBE Ratcheting Wrench Set from multiple verified stores:

Summary

The IRONCUBE Ratcheting Wrench Set is a top-tier choice for professional workshops and DIY enthusiasts alike. With its superior build quality, ergonomic design, and versatile features, it’s a tool that delivers unmatched performance and durability. Whether you’re working on automotive repairs, industrial maintenance, or home projects, this set is a must-have addition to your toolkit.

Whether you’re a professional mechanic or a DIY expert, investing in an IRONCUBE Ratcheting Wrench Set is a decision that guarantees efficiency, durability, and satisfaction.

FAQs

Q1: What’s the main benefit of a reversible ratcheting wrench?

It allows direction changes without removing the wrench, improving speed and convenience.

Q2: Are IRONCUBE ratcheting wrenches suitable for professional mechanics?

Absolutely! They’re crafted to meet professional-grade standards, offering strength, precision, and comfort.

Q3: Do these wrenches work for both metric and SAE fasteners?

Yes, IRONCUBE sets include both measurement systems, and you can refer to the conversion chart for size reference.

Q4: Where can I buy genuine IRONCUBE products?

From IRONCUBE’s official store, Amazon, or through authorized distributors.

Q5: Can I get custom tool branding for my workshop?

Yes! Visit IRONCUBE Customized Tools for more information.