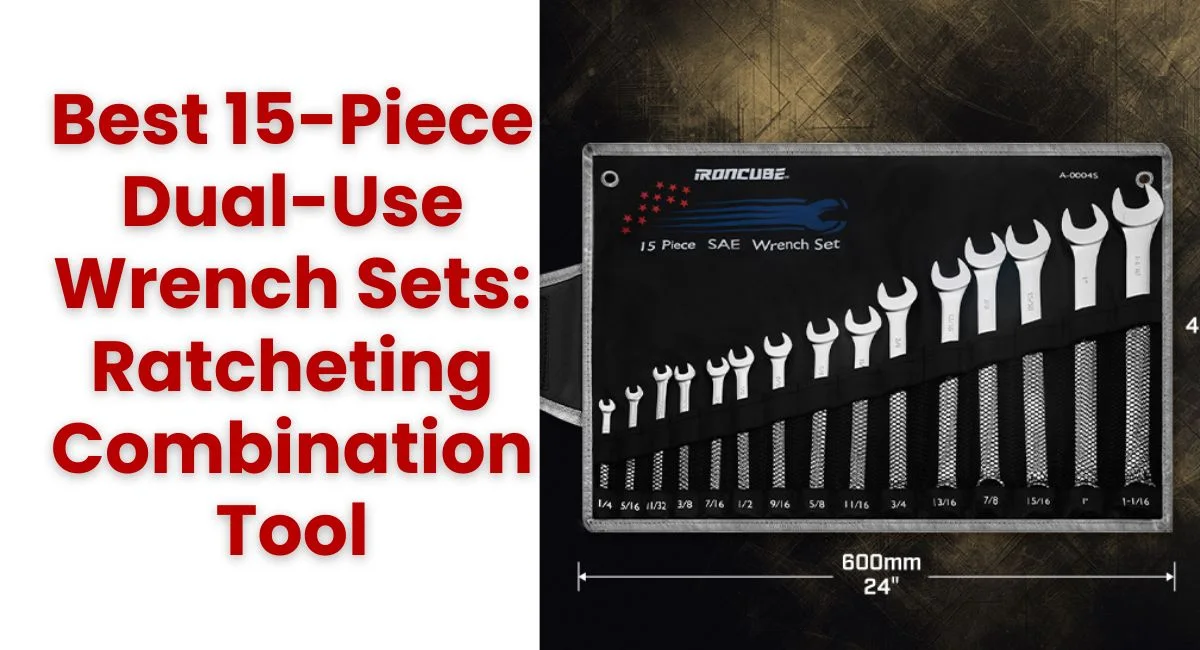

The IRONCUBE® 15-Piece Dual-Use Wrench Set, engineered for professionals who demand precision and durability. With a full range of metric sizes (8–22 mm), a 15° offset for tight spaces, and 20% extra length for torque, this set tackles automotive, industrial, and DIY tasks effortlessly. The average mechanic loses 3.5 hours per week hunting for the right wrench size. That’s 182 hours annually—nearly eight full workdays of lost productivity.

A complete 15-piece dual-use wrench set solves this problem by providing every common metric size from 8 mm to 22 mm in one organized kit. No more missing sizes. No more frustration.

What you need is a professional-grade solution—a versatile, durable, and complete best 15-piece dual-use wrench set that’s engineered for maximum speed and accessibility. This is why a high-quality, comprehensive set, like the ones we forge at IRONCUBE® WORKS, is non-negotiable for serious professionals and enthusiasts alike.

What is a 15-piece dual-use wrench set?

A 15 piece wrench set usually covers the core sizes mechanics and serious DIY users need every day, without gaps that slow work down. A “dual use” or combination design pairs an open end with a box or ratcheting box end on the same wrench, so you can switch from fast spinning to high-torque turns without changing tools.

IRONCUBE’s Best 15-piece dual-use wrench set focuses on those real workshop needs: complete metric coverage, high torque, and fast ratcheting action in cramped spots. That makes it a strong choice if you want one set that handles most automotive, machinery, and maintenance jobs with less toolbox clutter.

What Makes the Best 15-Piece Dual-Use Wrench Set Stand Out?

Ever wasted time lifting and repositioning a wrench after every turn? Traditional tools force that frustration on you—but a high-quality 15-piece dual-use wrench set changes the game.

1. Dual-Use Design: Speed Meets Precision

- Ratcheting Box End – No more lifting the wrench off the bolt. The 72-tooth mechanism lets you work in tight spaces with just a 5° swing.

- Open-End Flexibility – Quickly slide onto fasteners where a box end won’t fit.

- 12-Point Grip – Fits more bolt angles than a standard 6-point, reducing slippage.

2. Built to Last: Chrome Vanadium Steel

- Industrial Strength – Resists rounding, cracking, and wear even under heavy torque (80+ ft-lbs).

- Precision Machining – IRONCUBE® uses CNC-controlled forging to ensure exact tolerances—no sloppy fits.

3. No Missing Sizes = No Wasted Time

Budget sets skip sizes like 11mm or 15mm, leaving you scrambling mid-job. A professional-grade 15-piece set includes:

- 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, and 22mm

Covers European cars (13mm/15mm bolts), Japanese engines (10mm everywhere), and American machinery.

4. Why It Matters for Pros

- Billing by the Hour? Missing sizes cost you money in downtime.

- Tight Spaces? The 15° offset and ratcheting end save knuckles and frustration.

- Durability? CR-V steel means fewer replacements—tools that outlast the job.

Bottom Line: This isn’t just a wrench set. It’s a time-saving, frustration-proof system designed for mechanics who refuse to compromise.

Need the full set? Check our Amazon store or customize your own.

What Defines a High-Quality 15-Piece Dual-Use Wrench Set?

When it comes to professional-grade tools, the details make all the difference. Here’s what sets the best 15-piece dual-use wrench set apart from the rest:

The 15° Offset Advantage

- Knuckle Clearance – The angled head keeps your hands clear of obstacles like hoses, wiring harnesses, and frame rails.

- Tight-Space Access – Perfect for transverse-mounted engines, water pump bolts, and other confined areas.

- Efficiency Boost – Eliminates the need for awkward repositioning, saving time and frustration.

Extended Length for Leverage and Reach

- Physics at Work – A 12-inch wrench delivers 50 foot-pounds of torque with 50 pounds of force—compared to 41.7 foot-pounds on a 10-inch wrench.

- Deep-Set Bolts – Access recessed fasteners like transmission bellhousing bolts or HVAC compressor mounts without removing components.

- Heavy-Duty Use – Ideal for rusted suspension bolts, engine mounts, and other high-torque applications.

72-Tooth Ratcheting Mechanism

- Minimal Swing – Requires only 5° of arc to engage, compared to 10° for 36-tooth designs or 30° for 12-tooth ratchets.

- Confined-Space Efficiency – Essential for brake caliper work, intake manifold removal, and other tight-spot tasks.

- Smooth Operation – High tooth count reduces backlash for precise, controlled movements.

Complete Size Coverage

- No Missing Sizes – Includes 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, and 22mm wrenches.

- Universal Compatibility – Handles European vehicles (13mm/15mm bolts), Japanese engines (10mm everywhere), and American machinery.

- Time Saver – Eliminates interruptions caused by searching for missing sizes.

Chrome Vanadium Steel Construction

- Durability – Resists rounding, cracking, and wear even under heavy torque.

- Precision – CNC-controlled forging ensures exact tolerances—no sloppy fits.

- Professional-Grade – Meets DIN 3110 standards for high-performance tools.

Why These Features Matter for Professionals

- Billing by the Hour? Faster work means higher productivity.

- Tight Spaces? The 15° offset and 72-tooth ratcheting save time and frustration.

- Heavy-Duty Use? CR-V steel ensures tools that outlast the job.

Metric vs. SAE: Which 15-Piece Dual-Use Wrench Set

Metric systems dominate modern vehicles. Everything manufactured after 1980 in Europe and Asia uses metric fasteners. Most American vehicles switched to metric in the 1990s. If you primarily service cars, motorcycles, or modern machinery, metric is essential.

SAE (fractional inch) systems still appear on older American vehicles, agricultural equipment, and industrial machinery manufactured before 1980. Construction equipment often mixes both systems.

Many professionals need both. A metric best 15 piece dual use wrench set covers daily automotive work, while a companion SAE best 15 piece dual use wrench set handles specialty applications.

Why Metric?

- Dominates modern vehicles (post-1980 European and Asian models).

- Used in most American cars manufactured after the 1990s.

- Essential for daily automotive repairs, motorcycles, and machinery.

Common Metric Sizes and Their Applications

| Size (mm) | Primary Applications | Common Vehicles/Equipment |

|---|---|---|

| 8mm | Small electrical connectors, trim fasteners | Most import vehicles |

| 10mm | Engine covers, battery terminals, body panels | Honda, Toyota, Nissan (extremely common) |

| 12mm | Caliper bolts, suspension components | European and Asian vehicles |

| 13mm | Alternator bolts, engine mounts | BMW, Mercedes, Volkswagen |

| 14mm | Cylinder head bolts, spark plugs | Older metric vehicles |

| 17mm | Lug nuts, axle nuts | Most passenger vehicles |

| 19mm | Large suspension bolts, transmission pans | Trucks and SUVs |

| 22mm | Oxygen sensors, some lug nuts | Heavy-duty applications |

When SAE Still Matters

Agricultural equipment like tractors and combines predominantly use SAE fasteners. The same applies to vintage American vehicles and many industrial machines. If you maintain a fleet of pre-1990 Fords or Chevrolets, you’ll encounter 1/2″, 9/16″, 5/8″, and 3/4″ fasteners constantly.

The key is matching your toolkit to your work. Shops handling diverse equipment often maintain both metric and SAE sets rather than relying on adjustable wrenches that round off fastener heads.

Final Recommendation

- Primary Automotive Work? Go with a Metric Wrench Set.

- Older Equipment or Agriculture? Opt for an SAE Wrench Set.

- Diverse Needs? Invest in both for complete coverage.

Material Quality and Manufacturing Standards

Chrome Vanadium Steel: The Gold Standard

- Why the CR-V?

- Chromium adds hardness and corrosion resistance, ensuring the tool withstands harsh environments.

- Vanadium enhances strength and shock absorption, preventing cracks under high torque.

- Durability – Outlasts cheaper alloys, making it a long-term investment.

Precision Forging: Strength Through Structure

- Drop-Forging – Aligns the grain structure for maximum strength, unlike casting which creates weak points.

- Hydraulic Presses – IRONCUBE® uses controlled pressure to produce denser, more durable tools.

- Consistency – Ensures every wrench meets exact specifications, critical for professional use.

Heat Treatment: The Balance of Hardness and Toughness

- Rockwell Ratings – Tools are hardened to precise levels to avoid flexing (too soft) or cracking (too hard).

- High-Torque Capability – Withstands repeated heavy use without deformation.

- Longevity – Built to handle years of demanding applications.

Mirror-Chrome Finish: More Than Just Looks

- Rust Protection – The coating prevents corrosion, even in humid or oily environments.

- Easy Cleaning – Oil and grime wipe off effortlessly, maintaining a professional appearance.

- Durability – Resists scratches and wear, keeping tools looking and performing like new.

REACH Compliance: Environmentally Responsible Manufacturing

- What is REACH? – A European regulation limiting hazardous substances in manufacturing.

- IRONCUBE®’s Commitment – Uses eco-friendly raw materials that meet REACH and other international standards.

- Why It Matters – Ensures tools are safe for users and the environment, while reflecting overall quality control.

Why These Standards Matter for Professionals

- Reliability – Tools that won’t fail mid-job, saving time and frustration.

- Longevity – Fewer replacements mean lower long-term costs.

- Environmental Responsibility – Supports sustainable practices without compromising performance.

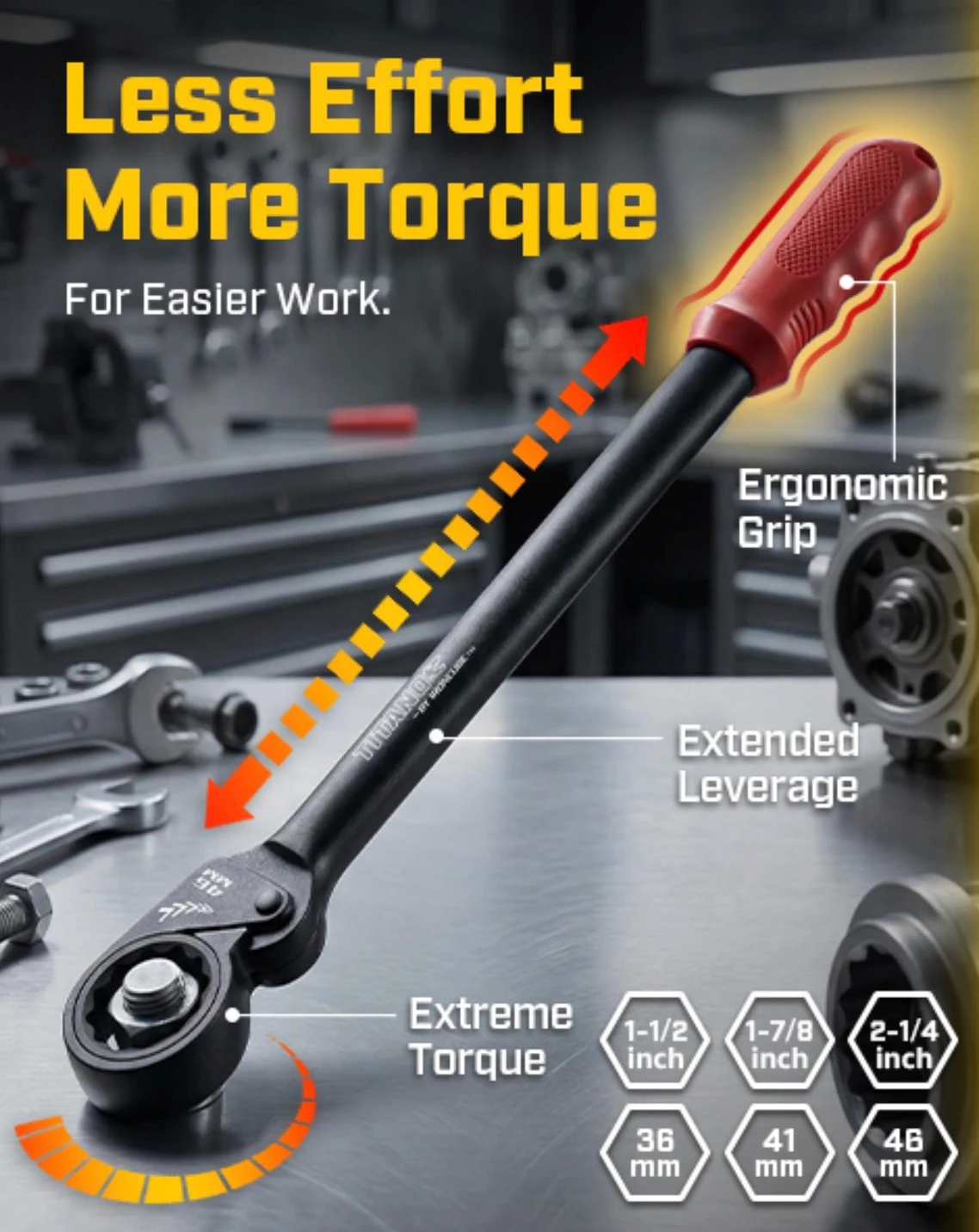

Extra-Long Design: Reach and Maximum Torque

Sometimes, the challenge isn’t the space around the bolt, but the depth of its location or the sheer force required to turn it. This is where the size and leverage of your tool become paramount.

Our wrenches are intentionally designed to be approximately 20% longer than many standard wrenches on the market. This extended length is a calculated feature with two major benefits:

Extended Reach: The longer tool allows you to access deep-set fasteners often found in heavy equipment, engine bays, or industrial assemblies. You can reach nuts and bolts without needing to disassemble surrounding components unnecessarily.

Superior Leverage and Torque: Physics is on your side. A longer handle means you can apply significantly more rotational force (torque) with the same amount of effort. This is essential for breaking free stubborn, rusted, or overtightened fasteners, saving time and preventing stripped bolts.

This extra length makes our best 15-piece dual-use wrench set a preferred choice for heavy machinery work, construction, and high-torque industrial applications.

The Versatility of the Combination End

The “dual-use” nature refers to the tool being a combination wrench, featuring an open-end on one side and a ratcheting box end on the other.

Open End: Ideal for quickly running down nuts once they are broken loose, or for working with tubing nuts and line connections where a box end cannot be fitted.

12-Point Box End: Our box ends feature a 12-point design. This provides double the engagement points of a 6-point, making it easier to slip onto the fastener in tight, low-visibility areas. When combined with the ratcheting action and the exact dimensions for a perfect fit, it ensures a superior grip, allowing for greater torque without slippage and protecting your nuts from wear.

This perfect fit and durable design are a core part of the IRONCUBE® promise. Our production capabilities, which include CNC machining centers and forging workshops, ensure every single tool meets exacting standards.

Budget vs. Professional-Grade Wrench Sets

| Feature | Budget Sets ($30-50) | Professional Grade ($80-150) |

|---|---|---|

| Material | Carbon steel or low-grade alloy | Chrome vanadium steel (Cr-V) |

| Finish | Basic chrome plating (chips easily) | Mirror polish, corrosion-resistant |

| Box End Fit | 12-point, loose tolerance | 12-point, precision machined |

| Offset Angle | 0-10 degrees or none | 15 degrees for clearance |

| Ratcheting Mechanism | 36-48 teeth, plastic pawls | 72 teeth, hardened steel internals |

| Length | Standard dimensions | 20% longer for leverage |

| Size Coverage | Often skips sizes (12 pieces advertised as 15) | Complete 8-22mm range |

| Warranty | 90 days or none | 24+ months with support |

| Manufacturing | Mass production, inconsistent QC | CNC machining, strict tolerances |

Long-Term Savings – A $100 professional set that lasts a decade is cheaper than replacing a $40 set three times over five years.

Efficiency – Fewer tool failures mean less downtime and higher productivity.

Reliability – Tools that won’t fail mid-job, even under heavy use.

Upgrade Your Toolkit

- Shop the Professional-Grade Wrench Set

- Explore our full hand tools collection

- Contact us for OEM inquiries

How to Choose the Right 15-Piece Dual-Use Wrench Set for Your Needs

Selecting the best wrench set isn’t just about picking a tool—it’s about finding the right fit for your workflow. Here’s a step-by-step guide to help you make the perfect choice:

How to Choose the Right 15-Piece Dual-Use Wrench Set for Your Needs

Selecting the best wrench set isn’t just about picking a tool—it’s about finding the right fit for your workflow. Here’s a step-by-step guide to help you make the perfect choice:

1. Assess Your Primary Applications

- Japanese Vehicles: Prioritize metric sizes, especially 10mm (the most common size in these vehicles).

- European Cars: Ensure the set includes 13mm, 15mm, and 17mm, frequently used in these models.

- Industrial Machinery: Check for larger sizes like 19mm and 22mm for heavy-duty applications.

2. Consider Your Work Environment

- Mobile Technicians: Opt for portable storage solutions like rolling pouches for easy transport.

- Shop Mechanics: Choose wall-mounted organizers for efficient tool access.

3. Evaluate Usage Frequency

- Daily Professional Use: Invest in premium tools with extended warranties and durable materials like chrome vanadium steel.

- Weekend DIY Projects: Budget-friendly options may suffice for occasional use.

4. Verify the Size Range

- Avoid Gaps: Some sets advertise “15-piece” but skip common sizes. Ensure the set includes 8–22mm without missing any critical sizes.

5. Examine the Ratcheting Mechanism

- Higher Tooth Count: Look for 72-tooth ratcheting for finer control in tight spaces.

- Efficiency: Essential for tasks like brake caliper work or intake manifold removal.

Why Choose IRONCUBE® as Your Manufacturer?

Founded in Ningbo in 2008, IRONCUBE® has become a trusted name in European and American markets by focusing on high-quality, durable hand tools. Here’s what sets them apart:

- Manufacturing Expertise

- Operates CNC machining, forging, and hydraulic workshops.

- Partners with high-end manufacturers to ensure quality and variety.

- Customization Options

- Accepts OEM orders and supports customized designs tailored to your needs.

- Environmental Responsibility

- Uses eco-friendly raw materials that meet REACH and other international standards.

- Long-Term Reliability

- Combines strict quality control with robust customer support for a stable supply chain.

Final Thoughts

The best 15-piece dual-use wrench set becomes more than just another toolkit addition. It represents reliability when you’re under pressure, precision when tolerances matter, and durability through years of demanding use.

IRONCUBE® manufactures these tools with the understanding that your livelihood depends on them. From the CNC-machined box ends that fit fasteners perfectly to the 72-tooth ratcheting mechanisms that work in impossibly tight spaces, every detail serves a purpose.

Whether you’re maintaining a fleet of vehicles, servicing industrial equipment, or building a professional toolkit, complete size coverage from 8-22mm eliminates the frustration of missing tools. The 15-degree offset provides clearance where straight wrenches fail. Extended length delivers the leverage needed for stubborn fasteners.

Quality manufacturing using chrome vanadium steel and environmental compliance through REACH certification demonstrates commitment beyond just producing tools. It shows responsibility to craftspeople who depend on these wrenches and to the environment we all share.

The portable rolling pouch keeps everything organized and accessible, whether you’re in a shop or working on mobile service calls. No more digging through drawers or losing tools at job sites.

Visit IRONCUBE® WORKS to explore our complete range of hand tools and discover why professionals across Europe and America trust our manufacturing. Check our Combination Wrench Set Long SAE Set on Amazon or browse our complete selection of Wrenches Ratcheting on Amazon.

For wholesale inquiries, custom specifications, or OEM partnerships, our team stands ready to discuss your requirements. Contact us today to learn how IRONCUBE® can support your tool needs with manufacturing expertise built over nearly two decades.

Your tools should work as hard as you do. Choose quality that lasts.

FAQs

1. Can this wrench set be customized for OEM or bulk orders?

Yes. IRONCUBE® offers OEM customization including branding, packaging, and special materials through: https://ironcubeworks.com/customized/

2. What’s the expected lifespan under daily professional use?

With CR-V forging and anti-corrosion finishing, the set handles heavy daily workloads for years without bending or rounding.

3. Is this 15 piece wrench set suitable for automotive repair shops?

Absolutely. Mechanics favor it for the complete metric range, extended length, and tight-space offset.

4. Do you offer both metric and SAE versions?

Yes. Metric and SAE sets are available individually. See the SAE version here:

https://ironcubeworks.com/product/ironcube-15pcs-sae-combination-wrench-set-with-rolling-pouch/

5. What after-sales support is provided?

IRONCUBE® includes a 24-month warranty with easy replacements or exchanges.