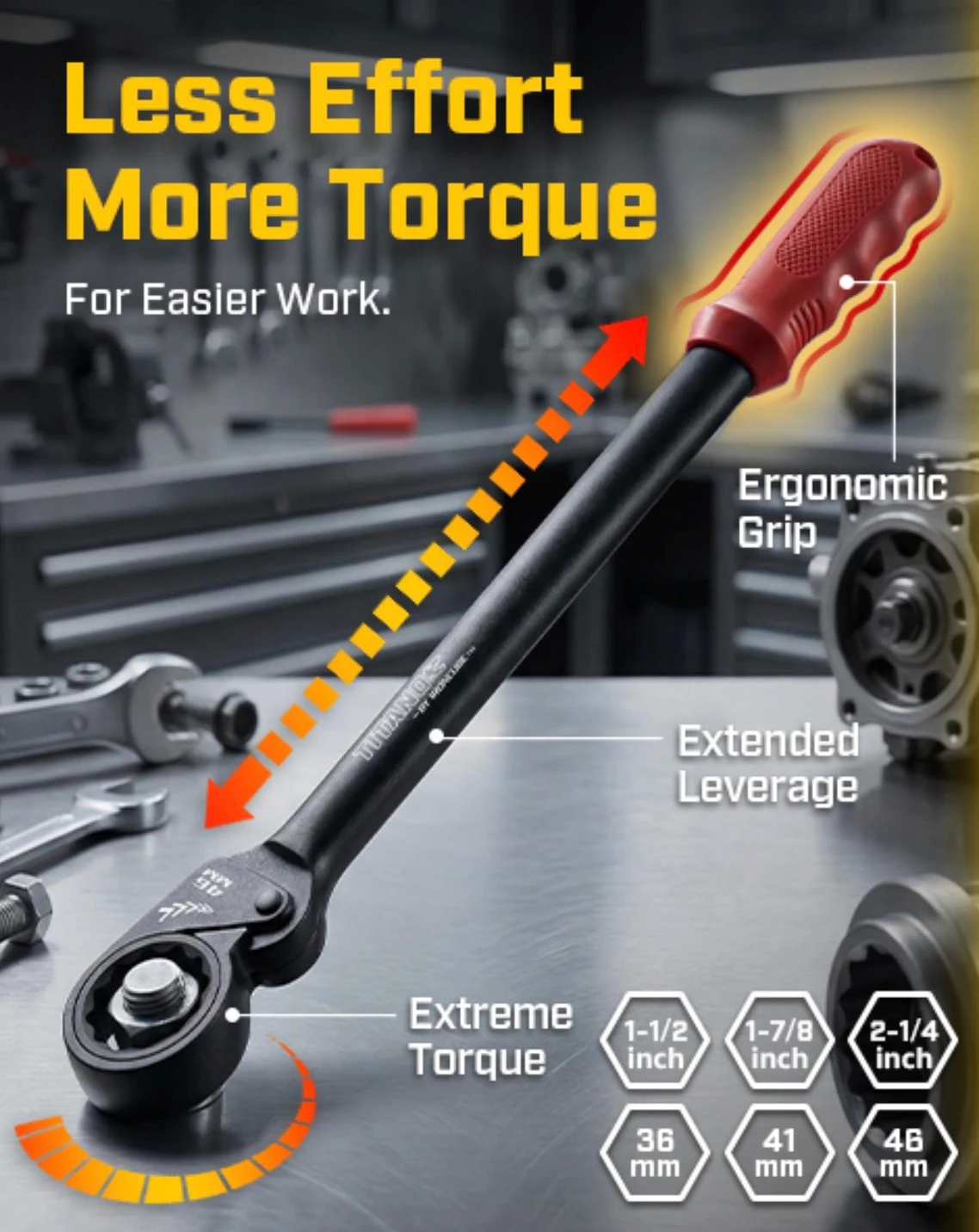

Craftsmen, engineers, and DIY enthusiasts all agree: the humble screwdriver bit is indispensable. But have you ever wondered how these essential tools are made? Buckle up for an eye-opening journey crafted just for you!

Why Screwdriver Bits Matter

Whether you’re assembling furniture or fixing your car, screwdriver bits are the unsung heroes. These bits are integral to industries like construction, automotive, and electronics. They may be small, but their significance is mammoth!

What the Heck Are Screwdriver Bits?

Let’s get the basics straight. Screwdriver bits are the interchangeable tips you insert into a screwdriver handle. It’s not the whole screwdriver, just the business end. Curious about pricing? Check out our comprehensive screwdriver price guide.

The Evolution of Screwdriver Bits

Before the dawn of machines, these bits were handcrafted, often toiling away blacksmiths. Today, sophisticated machinery churns them out by the second. The bits you hold today are the product of centuries of innovation.

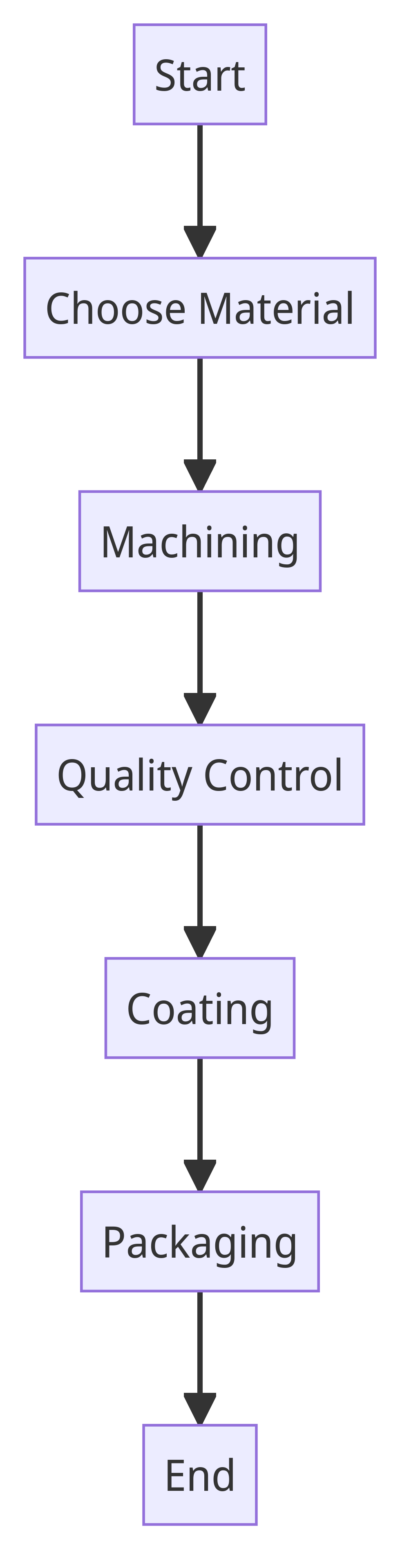

Mindmap: How Screwdriver Bits Are Made

Materials Making the Cut

When it comes to materials, stainless steel and high-carbon steel are the popular kids in the class. These materials offer the durability and strength needed in various applications. However, they do come with an environmental footprint—something the industry is working to reduce.

Manufacturing Magic: From Steel to Screwdriver Bits

Get ready for a peek behind the curtain! The manufacturing process involves multiple stages, from cutting to heat treatment. Automation and robotics also play their part in ensuring you get top-notch bits every time.

Flowchart: Manufacturing Process of Screwdriver Bits

The Bit Types You Never Knew You Needed

From Phillips to flat-head, the variety is endless. Want to know more? Specialty bits like Torx and Hex exist for unique applications. Each has its own features, making them vital for specific jobs. If you’re in the market for a new set, take a look at our screwdriver bit set price guide.

Eager for more? Stay tuned!

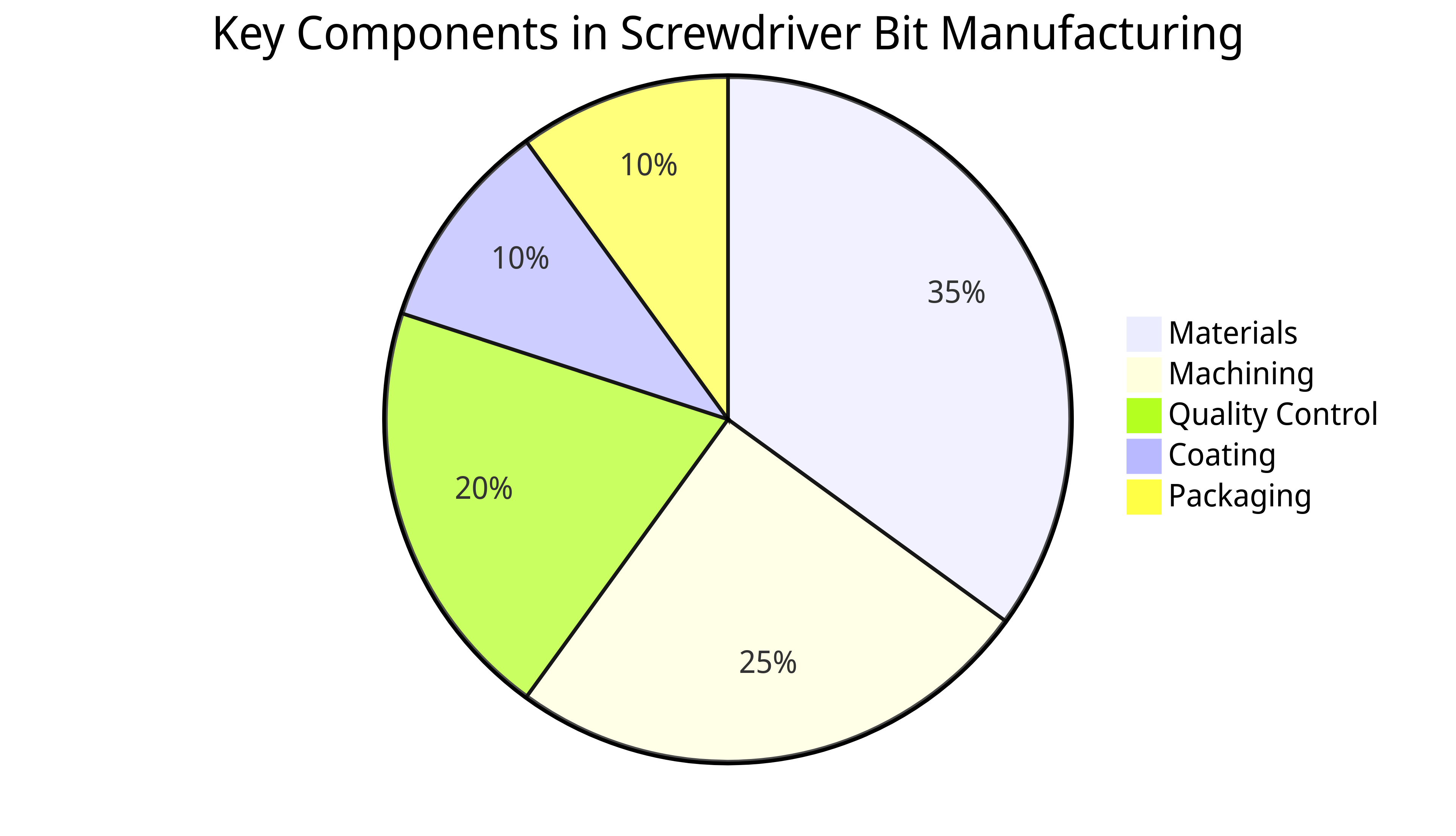

Ensuring Every Bit Counts: Quality Control

No one wants a subpar bit. That’s why strict quality control measures are in place. We’re talking ISO standards, certifications, and stringent inspections. These ensure the bits you get are the best of the best.

Molded vs Machined: The Showdown

Bits can either be machined or molded. Machined ones offer precision but can be pricier. Molded bits are generally cheaper but may lack in some quality aspects. It’s a classic trade-off.

Pie Chart: Key Components in Screwdriver Bit Manufacturing

Coatings and Treatments: The Cherry on Top

A bit isn’t ready until it’s treated and coated. These processes amplify durability and performance. So, you’ll find bits with various coatings to suit specific applications. Want to know about these processes? Take a look at how to make screwdriver bits magnetic.

That’s another chunk of our comprehensive guide. Excited to learn more? Stay with us!

Getting the Size Right: Understanding Bit Sizes

Size matters in the world of screwdriver bits. From tiny ones for intricate work to large bits for heavy-duty tasks, choosing the right size is crucial. Don’t know your size? Standard sizing charts can help. For a diverse set, our small screwdriver set price guide is a great start.

Safety First, Always

Goggles on, folks! When using screwdriver bits, safety can’t be compromised. Best practices and legal safety requirements exist for a reason. So, gear up and follow the guidelines.

Longevity in a Box: Storage and Maintenance

After investing in quality bits, you’d want them to last. Storage plays a huge role here. With simple DIY solutions, you can prolong your bits’ lives and get the most bang for your buck.

Dying for more insights? Don’t go anywhere!

Wisdom from the Wise: Expert Opinions

Get the lowdown from the pros. We’ve interviewed industry experts to bring you firsthand knowledge and tips. These experts’ credibility and qualifications are the real deal, offering you advice you can trust.

FAQs: Your Questions, Answered

Confused about something? You’re not alone. Our FAQ section addresses common questions and busts myths. Got a burning question? Head to how to use screwdriver bits to submit yours.

Wrapping It Up: Conclusion

We’ve covered the A to Z of screwdriver bits, from raw material to your toolkit. You’re now armed with the knowledge to make the right picks and use them wisely. The future? Expect smarter, more durable bits.

Ready for more? Stick around. We’re just getting started.

Dive Deeper: Additional Resources

Ready to become a screwdriver bit guru? Check out our curated list of books, online courses, and recommended brands. Elevate your toolkit and know-how to an unbeatable level.

In Plain English: Glossary

Confused by the jargon? Our glossary breaks down the technical terms used in this article. We even teach you how to pronounce them. No more head-scratching!

A Big Thanks: Acknowledgments

Kudos to the contributors and experts who lent their wisdom. Their contributions were verified for accuracy, giving you the peace of mind to trust what you read.

Meet the Writer: About the Author

Intrigued by who penned this guide? Meet the author, with credentials that back the insights provided. Explore other articles by the author for more wisdom.

Covering Our Bases: Legal Disclaimer

This guide aims to inform, not substitute for professional advice. For any inaccuracies, report them through our channels.

That wraps up our comprehensive guide on how screwdriver bits are made. Hope you found it enlightening! Stay tuned for more gems from IRONCUBE WORKS.