Mastering Hand Tool Maintenance: The Ultimate Guide

Hand tools are like the unsung heroes of your workshop. They grind day in and day out, often without a word of thanks. Poor maintenance doesn’t just dull their shine; it eats into your efficiency, safety, and the quality of your work. This comprehensive guide aims to educate you on how to keep your hand tools in pristine condition, ensuring that they last long and serve you well. Your tools are an investment—treat them as such.

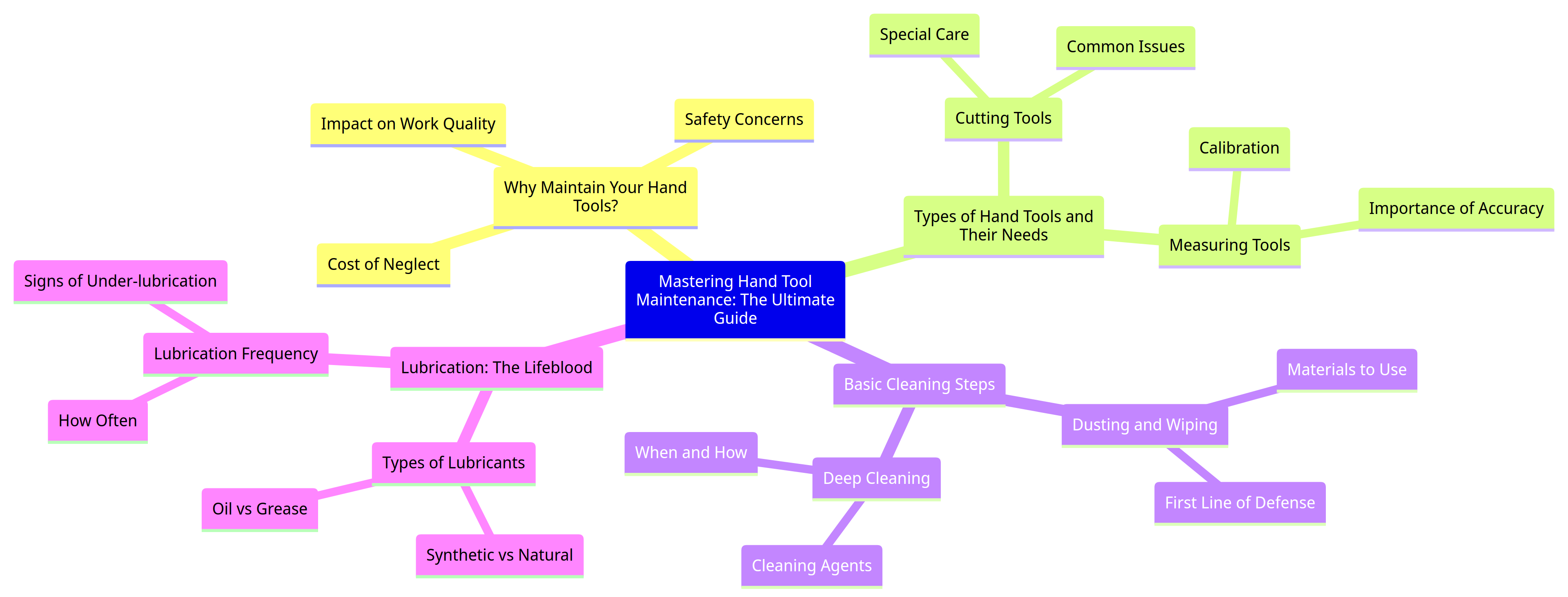

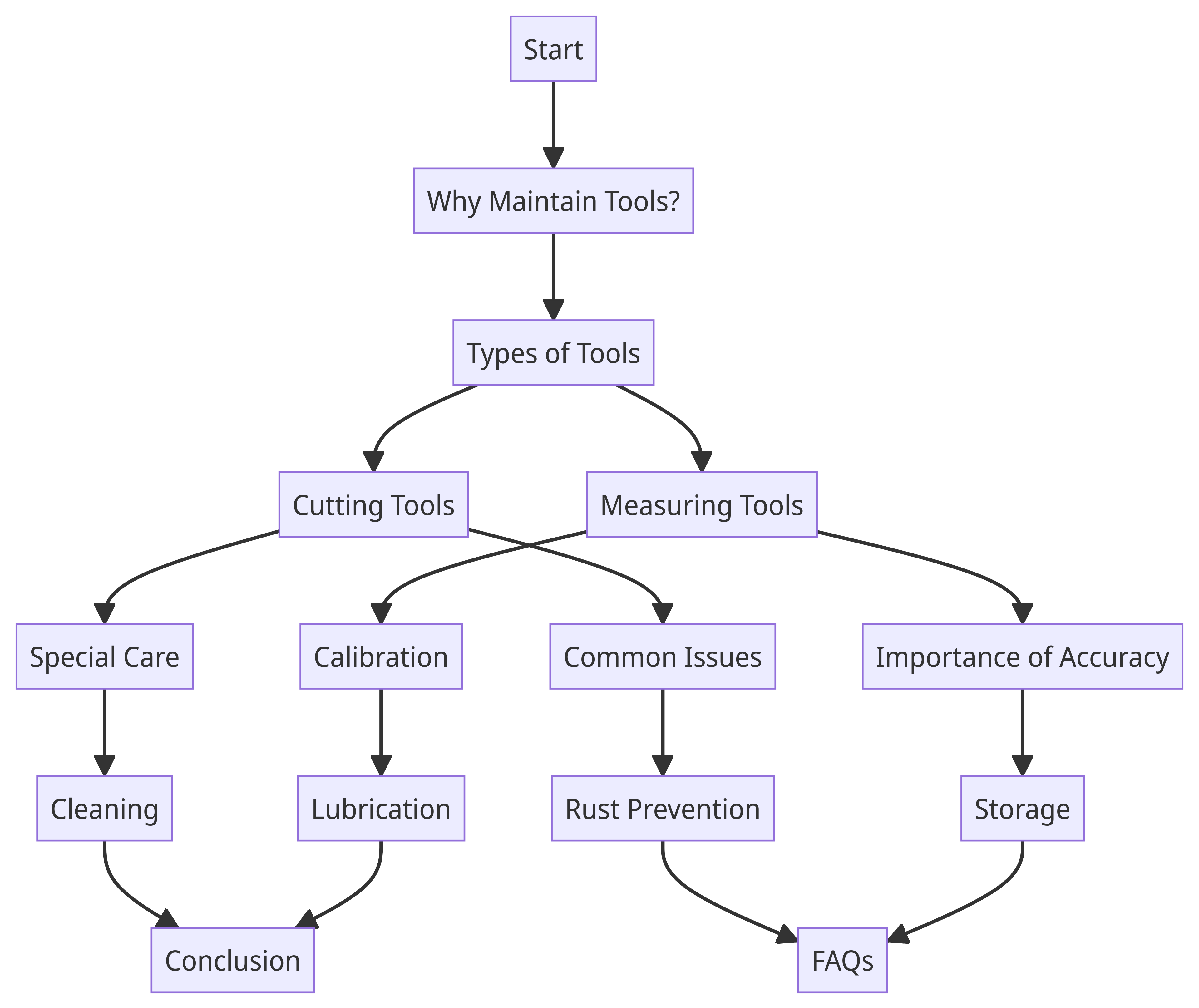

Why Maintain Your Hand Tools?

Let’s cut to the chase—maintenance costs time and money. But weigh that against the cost of replacing your hand tools or worse, losing work quality or endangering your safety. A rusty wrench or a blunt blade can ruin your work, no matter your skill level. More importantly, failing to maintain your tools can be a safety hazard. Imagine a screwdriver that slips or a hammer that breaks mid-swing. Scary, isn’t it?

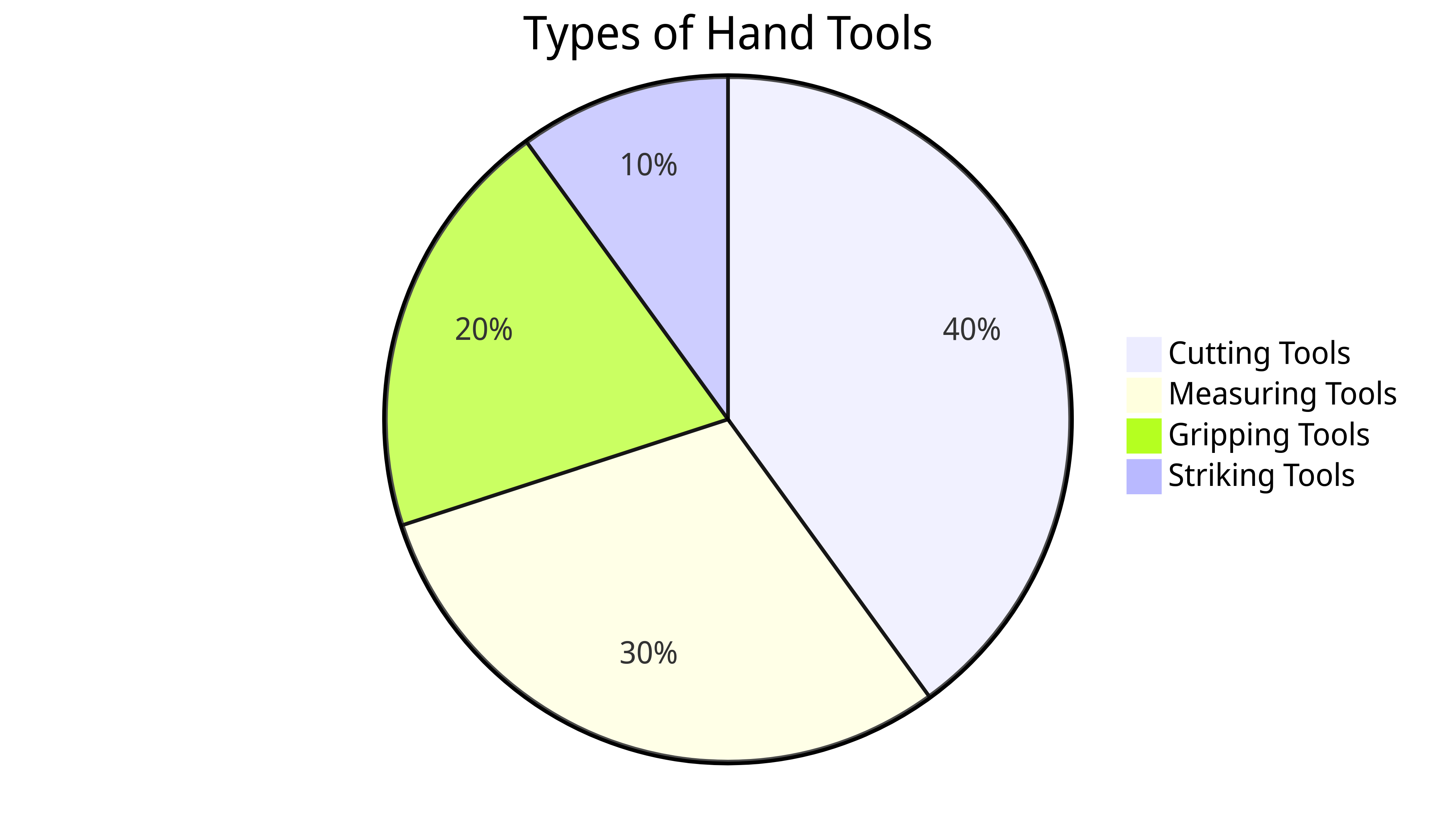

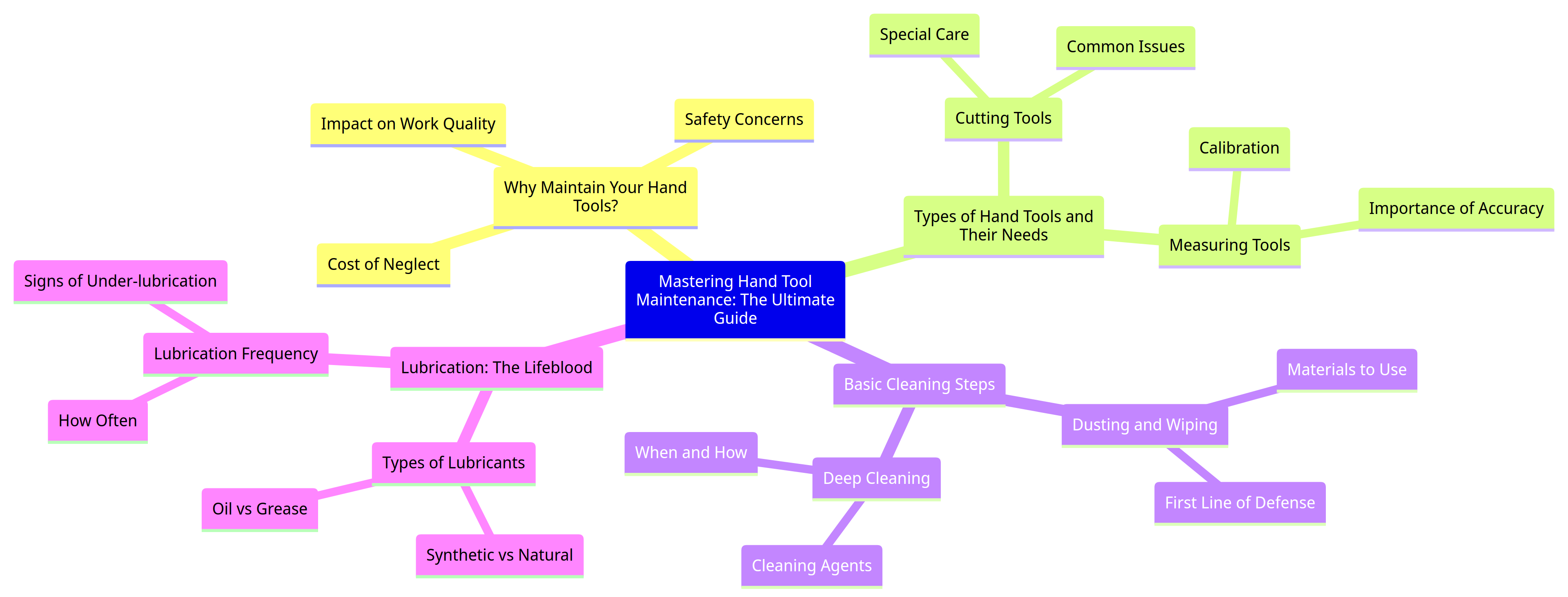

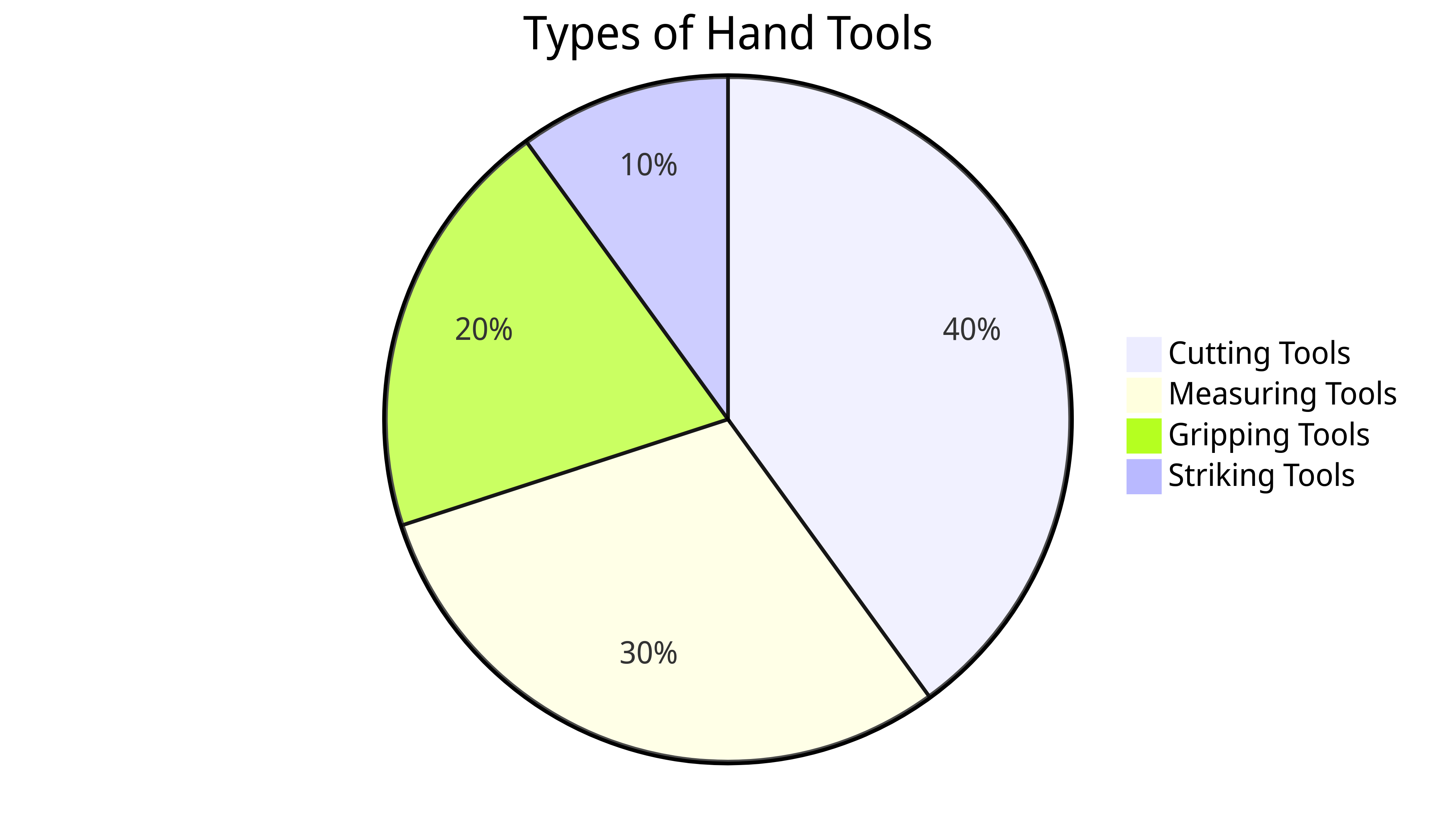

Types of Hand Tools and Their Needs

Cutting Tools

Sharp edges are the heart of any cutting tool. And just like the heart, they need special care to remain effective. Over time, tools like knives and scissors suffer from dullness and rust, hindering your efficiency. A dull tool requires more force, making your work sloppy and you more susceptible to accidents.

Measuring Tools

For measuring tools like calipers and rulers, accuracy is the name of the game. Improper storage can lead to misalignment or warping. Regular calibration ensures you’re not a millimeter off, saving you from project disasters down the line.

Basic Cleaning Steps

Dusting and Wiping

Dust and debris are your tools’ arch-enemies. A simple dust-off or wipe-down after each use can save you from bigger problems later. Use a soft, damp cloth for wiping. For tools with intricate parts, a quick blast of compressed air can do wonders. This is your first line of defense against wear and tear.

Deep Cleaning

Sometimes, a good wipe just won’t cut it. That’s when deep cleaning comes into play. Choose cleaning agents that are suited for the material of your tools. For metal parts, consider rust-removers or specialized metal cleaners. Be sure to follow all safety precautions when using any cleaning agents.

Lubrication: The Lifeblood

Types of Lubricants

You have choices here: oil or grease, synthetic or natural. Oil is great for moving parts but tends to evaporate faster. Grease lasts longer but can attract dirt. Synthetic lubricants offer high performance, while natural ones are eco-friendly. Choose wisely based on the type and frequency of tool use.

Lubrication Frequency

How often should you grease the groove? Too little and you risk wear and tear; too much and you’re wading in a slippery mess. Signs of under-lubrication include squeaking, resistance, and poor performance. Your tools will talk to you—listen to them.

Rust Prevention

Causes of Rust

Moisture is the prime culprit, but did you know that certain metals are more susceptible? Carbon steel, for example, rusts quicker than stainless steel. Understand your tools to tailor your rust prevention strategy.

Rust-Proofing Methods

Want to keep rust at bay? Consider coatings like lacquer or rust-resistant paint. For DIY options, even a rub-down with mineral oil can help. There are also moisture-absorbing solutions like silica gel packets that can keep your toolbox dry.

Storage Solutions

Toolboxes

There’s something classic about a toolbox, right? But not all boxes are created equal. Material matters—metal boxes offer durability while plastic ones are lighter. If you’re choosing a toolbox, also consider the layout and number of compartments for better organization.

Wall Storage

Feeling a bit more adventurous? Wall storage is not just functional; it’s an aesthetic statement. Pegboards are a popular DIY option. On the commercial side, magnetic strips and specialized tool racks can also do the trick. Whatever you choose, make sure it accommodates the variety of tools you own.

Seasonal Maintenance

Winter Care

Cold weather can be tough on your tools. Metals contract, lubricants thicken, and batteries lose charge faster. A heated storage space can work wonders here. If that’s not an option, at least store your most sensitive tools indoors during winter.

Summer Care

Heat and humidity are your enemies in summer. High temperatures can cause some materials to expand or even warp. Ventilation is key here. Also, never store your tools in direct sunlight. Keep your toolbox in a cool, dry place to combat humidity.

Professional Tips

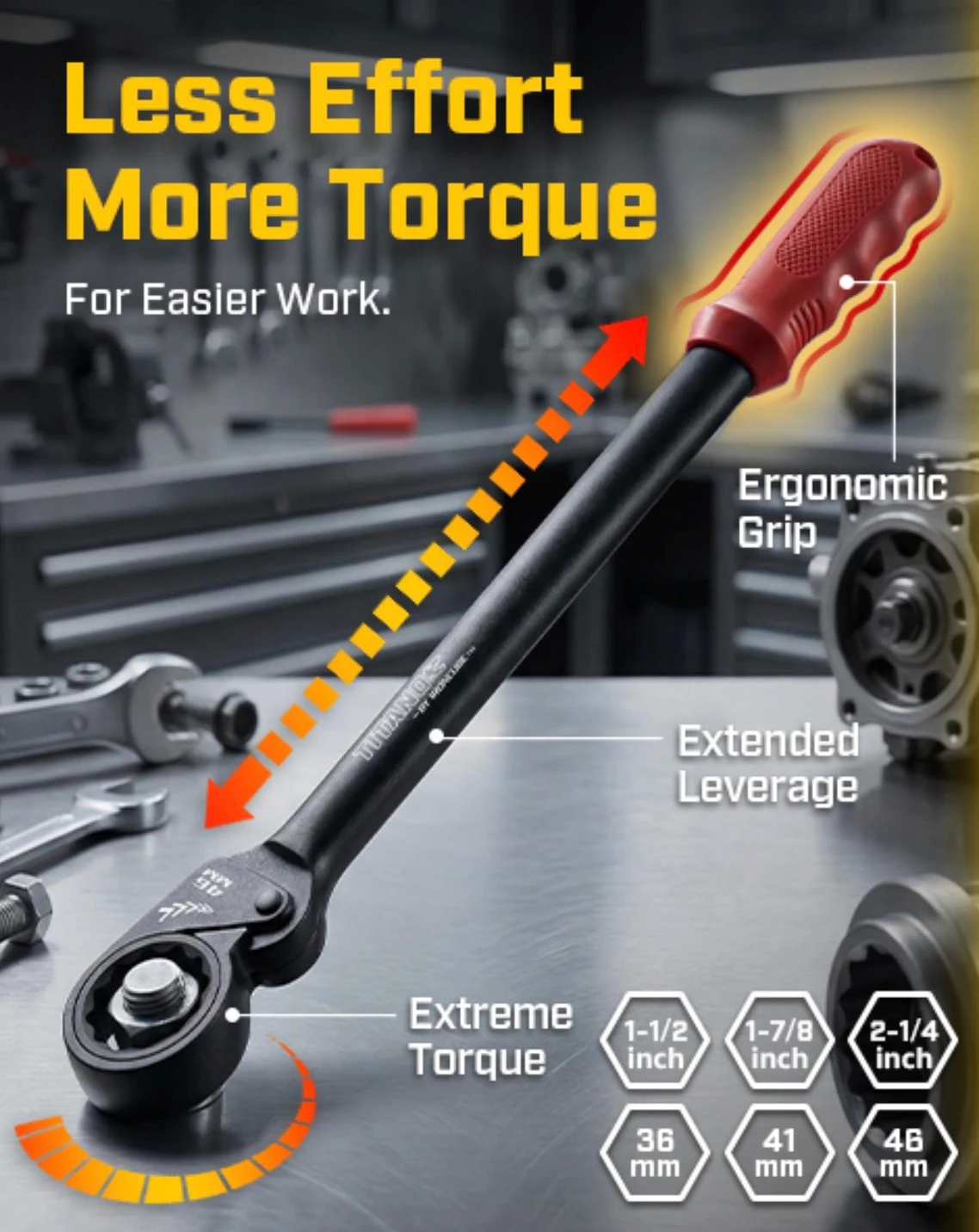

When to Replace Tools

All good things must come to an end, and so will your tools. Look for obvious signs like cracks, corrosion, or wobbly parts. If repairs cost almost as much as a new tool, it’s time for a replacement. Our 17mm ratchet wrench could be the high-quality replacement you need.

DIY vs Professional Service

To hire or not to hire—that’s the question. Simple maintenance can often be a DIY project, but some tasks demand the touch of a pro. If you’re not sure, consider the cost of a professional service against the value of your tool. Sometimes, expert help can extend your tool’s lifespan significantly.

Data-Backed Benefits

Why invest in maintenance? The answer is simple: it pays off. Studies have shown that regular upkeep can extend the lifespan of your tools by up to 40%. That’s not just saving money, but also contributing to sustainability. Less waste, less frequent replacements, more value for your buck. It’s a win-win situation for both your pocket and the planet.

FAQs

Can I use WD-40 for all tools?

In a word, no. WD-40 is a great general-purpose lubricant and cleaner but it’s not ideal for every tool. For instance, it shouldn’t be used on torque wrenches as it can alter torque settings. Explore alternatives like silicone or lithium grease for specific applications.

How often should I sharpen cutting tools?

Here’s where data steps in. Industry standards suggest sharpening your cutting tools every 10 to 12 hours of active use. Stick to the range and you’ll get consistent performance. For top-notch cutting tools, check out our super thin wrench set.

Conclusion

In wrapping up, maintenance is more than a chore; it’s a long-term commitment. Like anything valuable in life, your tools need love and care. By following these guidelines, you’re not just preserving tools; you’re elevating your work quality and ensuring safety. Make “The IRONCUBE Way” your way and reap the benefits of unmatchable quality and performance.

Additional Resources

Hungry for more knowledge? We recommend a few must-read books on tool maintenance, along with websites and courses for those who want to dig deeper. And if you’re looking for quality maintenance products, don’t hesitate to browse our full wrench set.