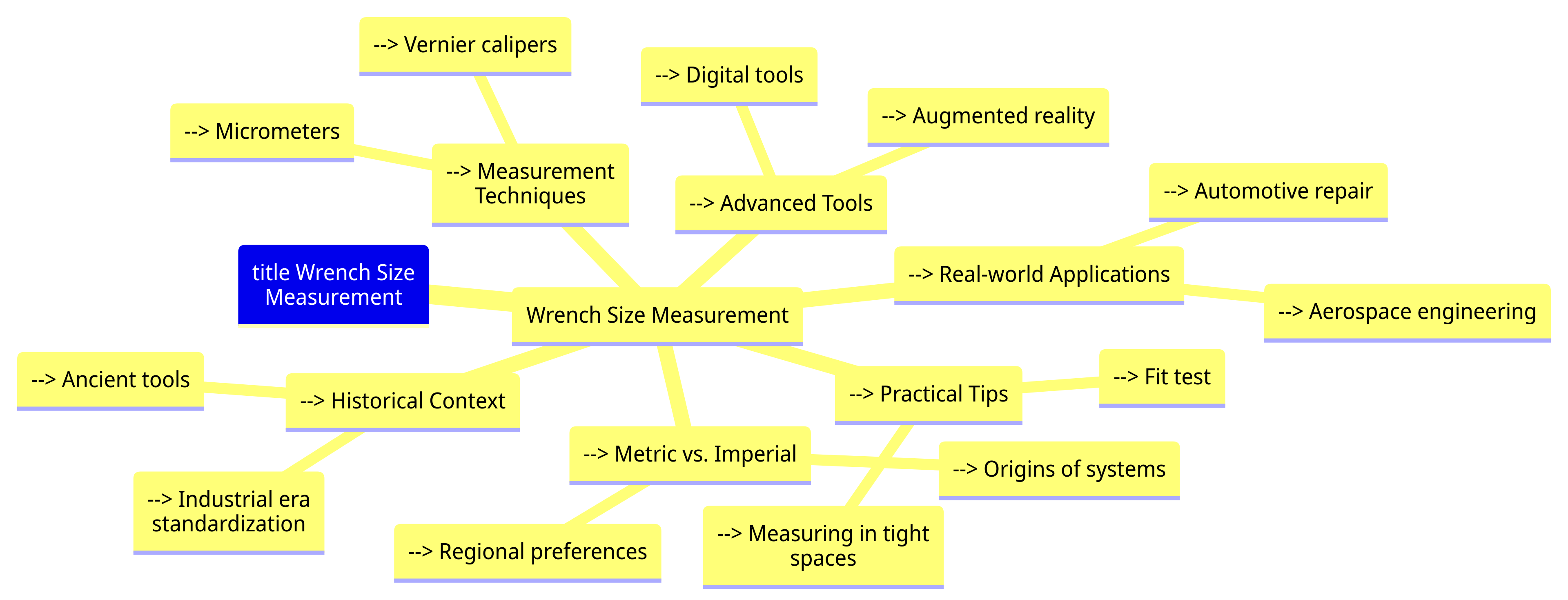

How To Measure A Wrench Size

Introduction

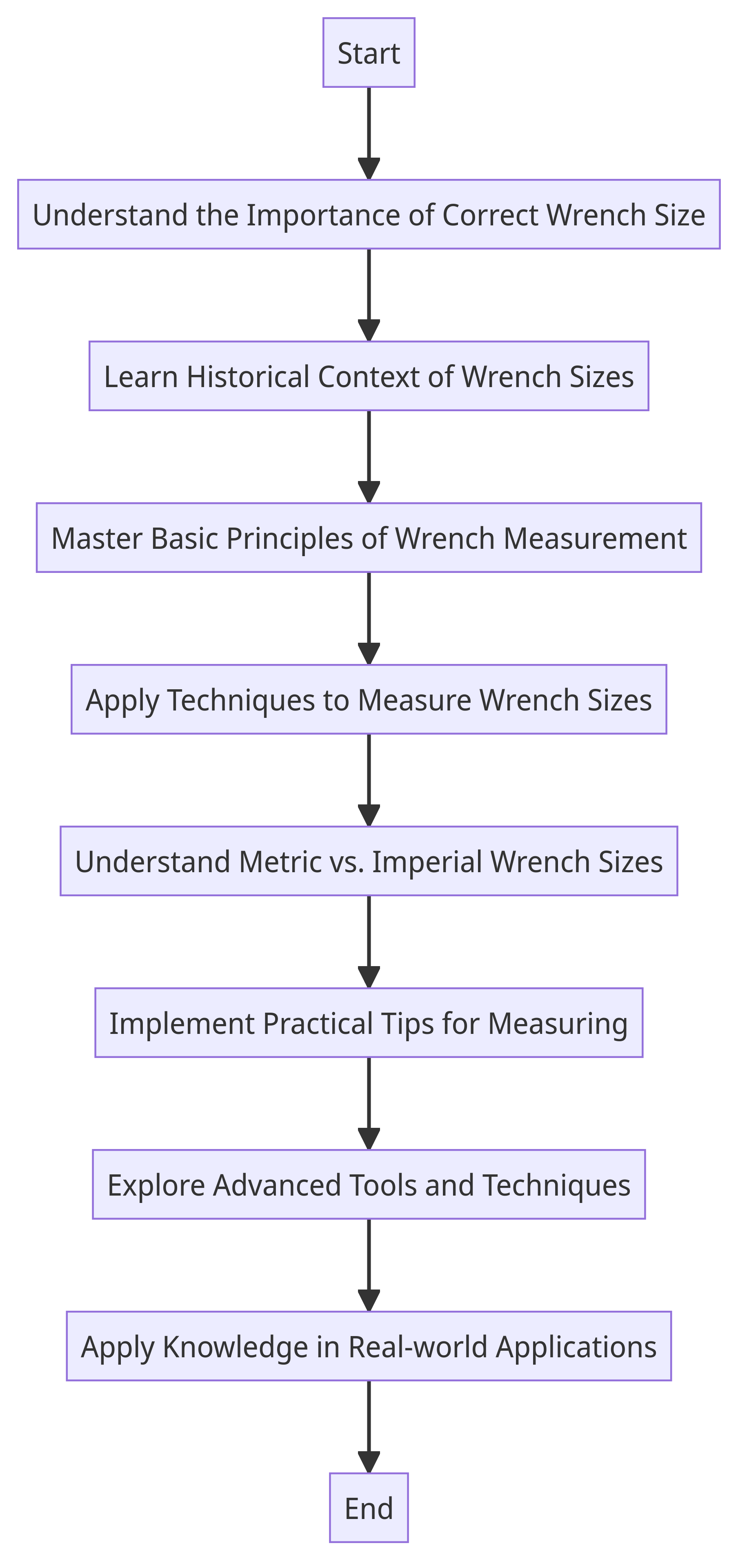

From the ancient Greeks’ simple tools to the sophisticated equipment we use today, wrenches have come a long way. But as their designs evolved, so did the importance of precision. Picture this: A car’s engine – a marvel of engineering – yet one misfit wrench could spell disaster. Yes, the right wrench size is more than just a convenience; it’s essential for your equipment’s long-term health.

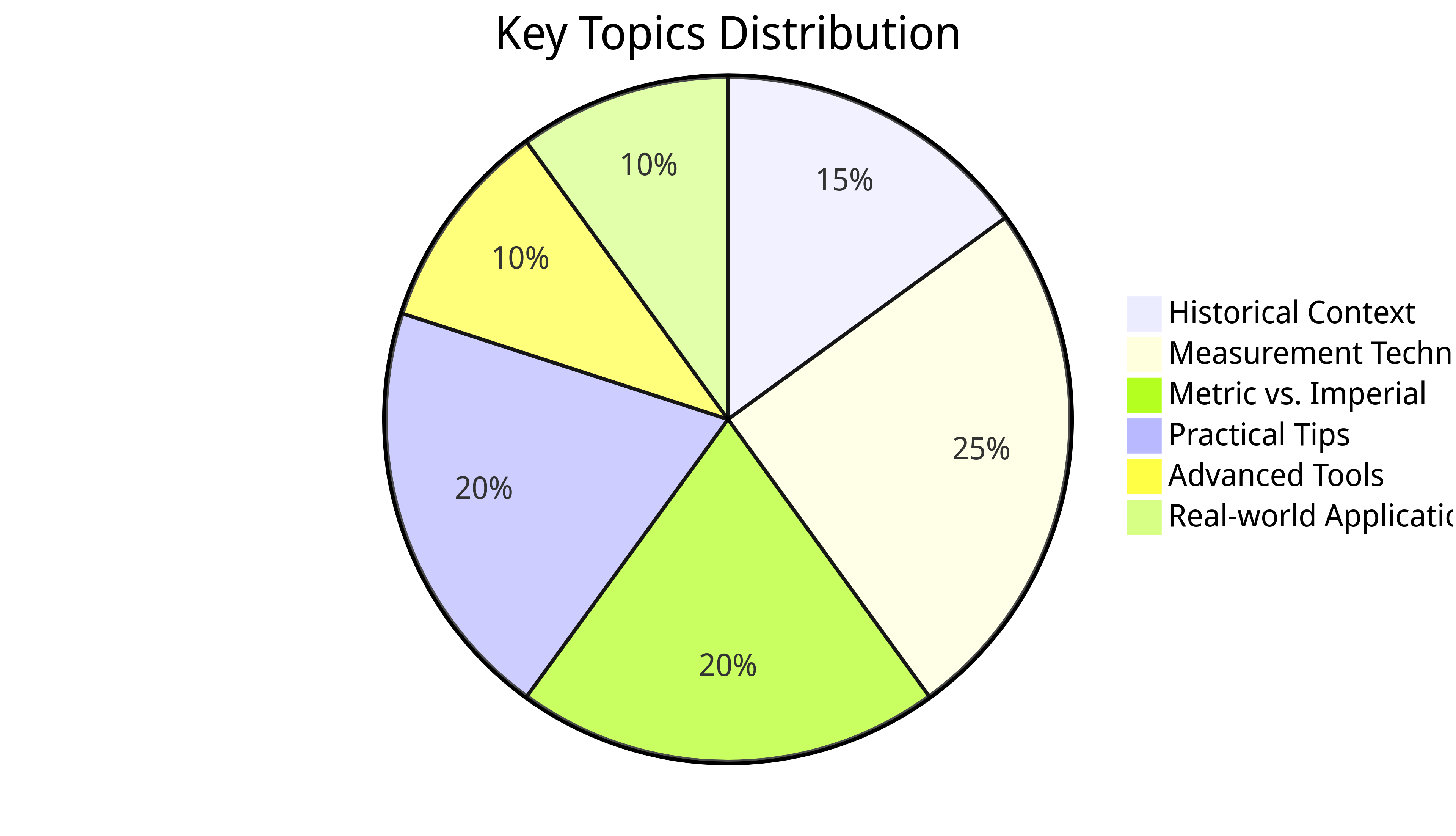

Historical Context of Wrench Sizes

Turn back the clock, and you’d see craftsmen forging tools by hand. These ancient tools, fascinating as they were, lacked consistency. But then came the Industrial Revolution! A game-changer. Machines began producing wrenches, bringing uniformity to the table. And soon, the wild west of wrench sizes saw standardization, ensuring that a 10mm wrench from IRONCUBE WORKS was the same as any other 10mm wrench.

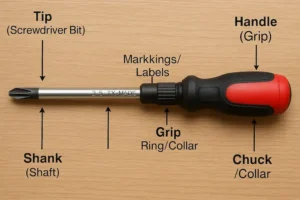

Basic Principles of Wrench Measurement

Wrenches might look simple, but the science behind their size determination? Not so much. We’ve got the head, the shank, the drive end – each part playing a unique role in measurement. And while Joe from next door might say “size is just size”, professionals know it’s more nuanced. The world has set standards, ensuring that when you pick a wrench, especially one from a reputable manufacturer like IRONCUBE WORKS, it’s the size you need.

Techniques to Measure Wrench Sizes

You’ve got a wrench, but how do you truly know its size? Enter the vernier caliper – a tool that’s been by the side of many mechanics and DIY enthusiasts. A quick slide and you’ve got your measurement. But sometimes, we need to be even more precise. That’s where micrometers strut onto the stage. They’re for those moments when you have zero room for error. And here’s a little secret: while external dimensions are talked about often, insiders know the power of measuring the internal dimensions too. After all, it’s what’s on the inside that counts, right?

Metric vs. Imperial Wrench Sizes

Ah, the age-old debate. Metric or Imperial? If we travel back in time, we’d witness the birth of these systems, each rooted in its own history. While Europe embraced the metric, the US swung the imperial way. And boy, have there been squabbles! But fret not, for those quick on their feet, mental conversions can be a breeze. Just remember, it’s not about which is better, but which is right for the job. Want a peek into what the world prefers? Check out the variety at IRONCUBE WORKS.

Practical Tips for Measuring Wrench Sizes

Real-world scenarios often throw us curveballs. So, what do you do when you’re in a tight spot, literally? You use the “fit test” – a hands-on, old-school method. Slide that wrench over the bolt; does it fit like a glove? Bingo! But wait, there’s more. Bolt depth is a sneaky factor many overlook. And when you’re working in spaces where it feels like you’re playing a game of Tetris, every millimeter counts.

Common Misconceptions about Wrench Sizes

Let’s bust some myths! First up, the “one-size-fits-all” wrench. If only it were that easy. But machinery is nuanced, and so are the tools that work on them. And those who think converting metric to imperial is just a numbers game? They’re in for a surprise. Here’s another zinger: wrench size doesn’t equate to bolt strength. So, before you muscle up on a bolt, make sure you’re wielding the right weapon from IRONCUBE WORKS.

Advanced Tools and Techniques

Welcome to the future of wrench measurements! Imagine a world where digital tools scan your bolts and auto-detect the perfect wrench size. Well, the future is now! Augmented reality is stepping into the arena, overlaying virtual measurements onto real-world objects. It’s like having a virtual assistant right in your toolbox. And as we gaze into the crystal ball, we see innovations galore. Wrench design and measurement are on the brink of yet another revolution. Curious about the cutting-edge tools? Dive into IRONCUBE WORKS to satiate your tech thirst.

Real-world Applications

Why all this fuss about wrench sizes? Let’s walk through some real-world scenarios. Picture a car repair shop. A mechanic dives under the hood, and with the right-sized wrench, it’s smooth sailing. But with the wrong size? They’re looking at potential damages and increased costs. And it’s not just cars. The aerospace industry, with its million-dollar equipment, hinges on precision. Even construction projects, building the skyscrapers we marvel at, lean heavily on accurate wrench measurements. Want tools that the pros trust? Head over to IRONCUBE WORKS.

Frequently Asked Questions

Ah, the burning questions! We’ve all had them. Let’s tackle a few:

Why do some wrenches have both metric and imperial measurements?

Well, it’s all about versatility. Living in a globalized world means working with both systems. Dual measurements? It’s like getting two wrenches for the price of one!How to measure the size of adjustable wrenches?

Trick question! These bad boys adjust. But if you’re talking about maximum jaw opening, then measure from one flat side to the opposite side when fully opened.What’s the difference between wrench size and socket size?

While they often match, wrench size refers to the dimension of the tool’s open end, while socket size is about the diameter of the tool’s drive hole. For the best of both worlds, explore the range at IRONCUBE WORKS.

Conclusion

From the humble origins of hand-forged tools to the high-tech digital measuring devices of today, wrench size measurement has evolved. But one thing remains unchanged: the importance of precision. In this age of automation, as machines take the wheel, it’s even more crucial to ensure your tools are up to par. Investing in quality tools isn’t just about the now; it’s about the longevity of your equipment. So, gear up, continue learning, and always aim for the best with IRONCUBE WORKS.

Additional Resources

Hungry for more? Dive deeper with these resources:

- Interactive Tools: There are apps galore that’ll help you measure wrench sizes in a jiffy.

- Online Communities: Join forums and communities where mechanics and DIY enthusiasts hang out. Share, learn, and grow.

- Books & Courses: For those wanting to master the art, there are numerous courses and books tailored just for you. And of course, don’t forget to explore the treasure trove at IRONCUBE WORKS.