What Are Box End Wrenches Used For

Introduction

Wrenches. They’re the unsung heroes of the toolbox. From fixing a leaky faucet to assembling a piece of furniture, they’ve got our backs. But among the vast array of wrenches, the box end wrench stands out. It’s not just another tool; it’s a testament to human ingenuity. Let’s dive into its world, from its humble beginnings to its modern-day marvels.

Ever wondered about the evolution of hand tools? The box end wrench has a story to tell. A story of innovation, precision, and sheer mechanical brilliance. But before we delve into its specifics, let’s take a step back and understand the broader picture of wrenches.

Historical Context of Wrenches

The wrench. It’s as old as the wheel. Well, not quite, but you get the drift. The history of wrenches is a fascinating journey, tracing back to ancient civilizations. They were the tools that built empires, connected cities, and powered revolutions.

Enter the industrial era, and the box end wrench began to shine. It wasn’t just another tool; it was a game-changer. With its unique design, it became an indispensable asset in major engineering projects. From constructing bridges to assembling machinery, the box end wrench was there, ensuring every bolt was tightened to perfection.

For a deeper dive into the world of wrenches, check out our comprehensive mindmap on the subject.

What is a Box End Wrench?

Imagine a tool, sleek in design, built for precision, and unmatched in its utility. That’s the box end wrench for you. Unlike its counterparts, it boasts a closed loop at one or both ends, designed specifically to fit hexagonal bolt heads and nuts.

But how does it compare to other wrenches? While the open-ended wrench grips from the side, the box end encircles the fastener, providing a better grip and reducing the risk of rounding off the edges. And when it comes to materials, most box end wrenches are made of high-quality steel, ensuring durability and resistance to wear.

Looking for more insights on different wrench types? Our article on combo wrenches offers a detailed comparison.

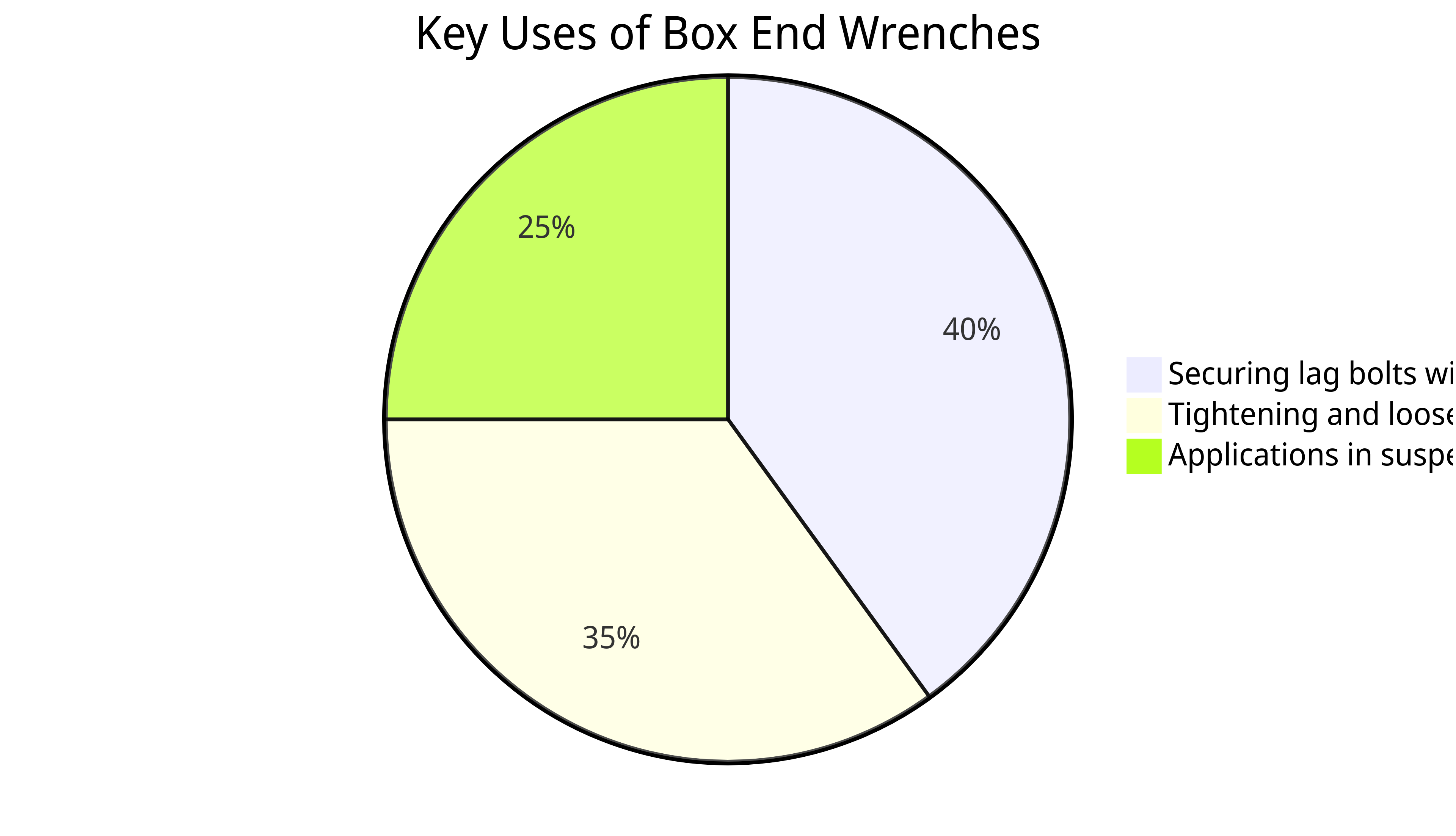

- Pie Chart – Key Uses of Box End Wrenches:

Key Uses of Box End Wrenches

Box end wrenches aren’t just for show; they’re workhorses. Here’s a snapshot of what they’re best at:

- Securing Lag Bolts: Got hexagonal heads? The box end wrench is your best friend. It ensures a snug fit, making the task a breeze.

- Automotive Repair: From adjusting suspensions to fine-tuning engines, this tool is a mechanic’s dream.

- Heavy Machinery Maintenance: Those massive machines aren’t going to fix themselves. And when precision is key, the box end wrench delivers.

For a visual breakdown of its applications, feast your eyes on this Pie Chart detailing the key uses of box end wrenches.

Advantages of Using Box End Wrenches

Why choose a box end wrench over its peers? Here’s why:

- Torque: Apply more force without damaging those precious fasteners.

- Tight Spaces: Its design is a lifesaver when space is at a premium.

- Dual Utility: Some models come with two different sizes on each end. Talk about multitasking!

- Comfort: Long hours? No problem. Reduced wear and tear on your hand means you can keep going.

If you’re keen on exploring more advanced tools, don’t miss our piece on the ratcheting flare nut wrench.

Box End vs. Open-Ended Wrenches

It’s the clash of the titans. Let’s break it down:

- Design: While the open-ended wrench grips from the side, the box end offers a 360-degree embrace of the fastener.

- Utility: Box end wrenches shine in tight spaces, while open-ended ones are great for quick tasks.

- Efficiency: Time is money. And with the box end wrench, you’re likely to save a lot of both.

Curious about open-ended wrenches? Dive into our detailed guide on open wrench sets.

Box End Wrench in Modern Applications

The modern world demands modern tools. And the box end wrench is more relevant than ever:

- Aerospace Engineering: Building rockets and aircraft requires precision. Enter the box end wrench.

- Automotive Excellence: From vintage cars to modern electric vehicles, this tool is indispensable.

- Construction Projects: Skyscrapers, bridges, or homes, the box end wrench is on the frontline, ensuring everything stands tall and strong.

- Mindmap – Box End Wrenches Comprehensive Guide:

Advanced Tools and Innovations

The world of wrenches isn’t static; it’s evolving, and fast. Here’s a peek into the future:

- Digital Tools: Gone are the days of guesswork. Modern wrenches come equipped with digital displays, ensuring precision every time.

- Augmented Reality: Imagine seeing a bolt and instantly knowing its size and the torque needed. AR is making it possible.

- Smart Wrenches: These aren’t your grandpa’s tools. With built-in sensors and connectivity, they can provide feedback, store data, and even guide you through tasks.

For those who love staying ahead of the curve, our article on smart wrench innovations is a must-read.

Practical Tips for Using Box End Wrenches

Using a box end wrench is an art. And like all arts, it has its secrets:

- The Fit Test: Always ensure the wrench size matches the fastener. A snug fit is key.

- Tight Spaces: When working in confined areas, angle the wrench for better leverage.

- Maintenance: Clean your wrench after use. A little care goes a long way in ensuring longevity.

If you’ve ever faced challenges measuring in tight spaces, our guide on how to measure a wrench size is a lifesaver.

Metric vs. Imperial Box End Wrenches

The age-old debate. Let’s settle it:

- Origins: While the metric system hails from Europe, the imperial system is rooted in British traditions.

- Preferences: Europe and most of Asia prefer metric, while the US still leans towards imperial.

- Conversion: Switching between the two? Our detailed guide on the differences between metric and standard wrench sets comes with handy conversion tables.

Safety Precautions

Tools are fun, but safety first:

- Handling: Always grip the wrench firmly. A loose grip can lead to accidents.

- Over-Torquing: Applying too much force can damage the fastener and the tool. Know the limits.

- Right Size: Using a wrench that’s too big or small can lead to slippage and injuries. Always choose the right size for the job.

For more on this, our article on the importance of using the right wrench size is a goldmine of information.

Conclusion

The box end wrench. It’s not just a tool; it’s a legacy. From ancient civilizations to modern aerospace projects, it’s been there, ensuring everything is held together just right. As we move into the future, its importance only grows. So, the next time you pick one up, remember its rich history and the countless hands that have shaped its evolution.

For those looking to expand their toolkit, our comprehensive wrench collection offers something for everyone.

FAQs

Q: Are box end wrenches better than open-ended ones?

- A: It depends on the task. For precision and tight spaces, box end wrenches are superior. For quick tasks, open-ended ones might be more convenient.

Q: How do I handle rust on my wrench?

- A: Regular maintenance is key. Clean and oil your wrenches regularly. If rust appears, a rust remover can help. For more, check out our guide on handling rust and wear.

Q: Where can I find the best wrench sets?

- A: Look no further! At IRONCUBE WORKS, we offer a range of high-quality wrench sets tailored for professionals.

- Flow Chart – Structured Flow of Box End Wrenches Guide: