Introduction

Got a squeaky door or assembling furniture? No matter the task, screwdriver bits are your go-to heroes. This article is the ultimate guide to screwdriver bits, whether you’re a novice or an expert.

What Are Screwdriver Bits?

Let’s start with the basics. A screwdriver bit is a metal piece that fits into a driver’s chuck. The bits have evolved over centuries, from ancient Egypt to modern carpentry. You’ll find these nifty items everywhere—building sites, garages, and even in your kitchen drawer.

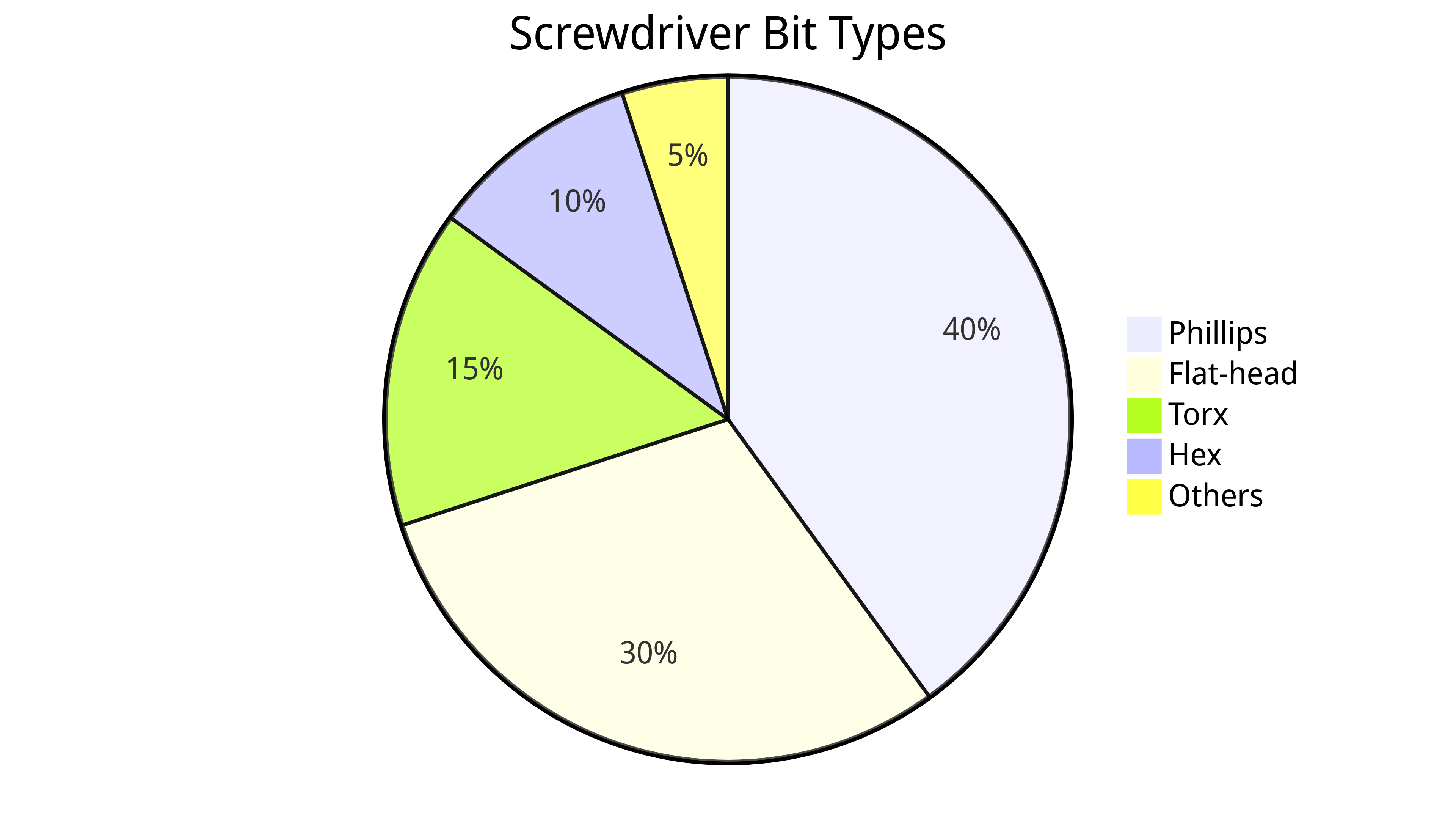

Types of Screwdriver Bits

Get this; there’s a smorgasbord of screwdriver bits to choose from! We’ve got the classics like Phillips and flat-head, but don’t forget the specialized ones like Torx and Hex.

- Phillips: Your everyday, go-to bit.

- Flat-Head: Perfect for simple screws.

- Torx: Got a car? You’ll need these.

- Hex: Think furniture assembly.

- Specialty Bits: These are your off-the-beaten-path bits, think security screws.

Ready to delve deeper? Let’s go!

Note: Want to ensure you’re getting the best bits for your buck? Check out IRONCUBE’s variety of screwdriver bit sets at unbeatable prices.

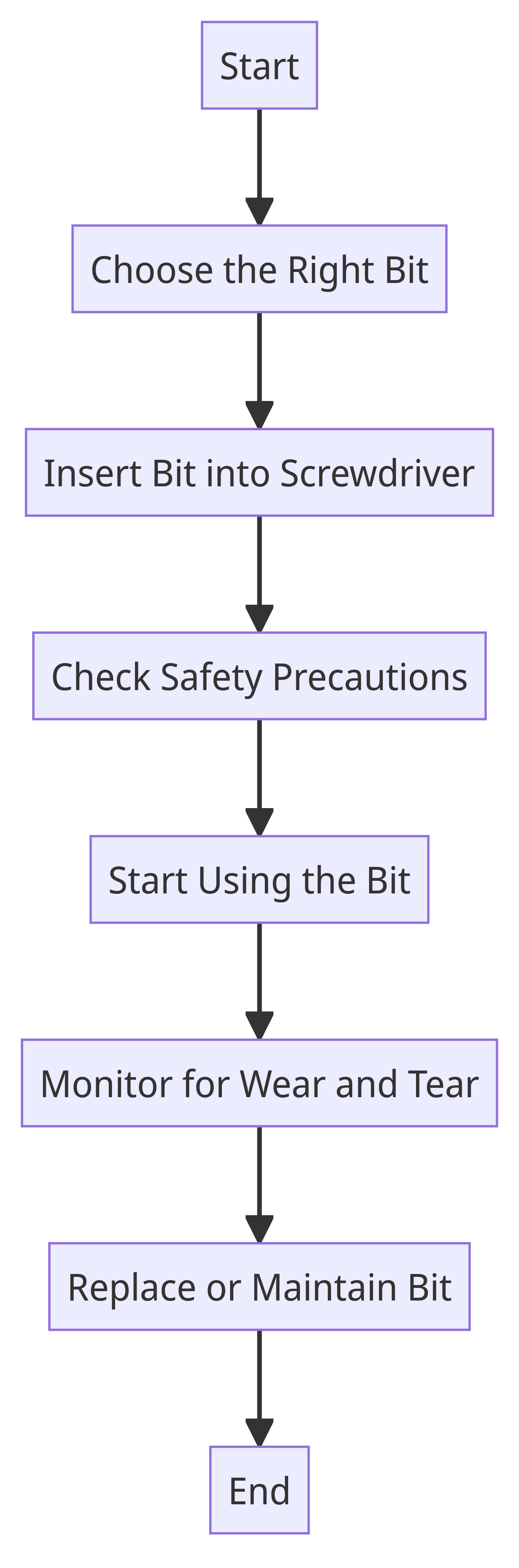

Inserting Bits into a Manual Screwdriver

You’ve got the bit, now what? Time for action. First, make sure the driver’s chuck is clean and free from debris. Next, follow these steps:

- Open the chuck by twisting it counterclockwise.

- Insert the bit firmly.

- Tighten the chuck clockwise.

Common Mistakes to Avoid: Over-tightening the chuck, or using a worn-out bit. These can lead to a world of hurt and botched projects.

Inserting Bits into a Power Drill

Power drill in hand? Safety first. Gloves on, safety goggles in place, and let’s get to it.

Steps:

- Unplug the drill or remove its battery.

- Open the drill’s chuck, slide in your chosen bit.

- Secure it by tightening the chuck.

Hot Tips: Make sure the bit is straight and locked in place to avoid any drill dramas.

Safety Precautions

Safety isn’t a joke; it’s a lifeline. Let’s keep it simple:

Gear Up:

- Safety goggles

- Gloves

- Ear protection

Environment Check:

- Well-ventilated area

- No flammable materials around

Electrical Safety:

- Unplug when not in use

- Check wires for frays

Ready to keep going? Let’s rock those bits and bolts!

Note: Need a full screwdriver set with all safety bells and whistles? Look no further than IRONCUBE’s top-rated screwdriver sets.

Choosing the Right Bit

So you’re geared up. Now, let’s pick your weapon—err, bit.

Material Considerations:

- Hardened steel for heavy-duty jobs.

- Carbon steel for general use.

Screw Type:

- Phillips for everyday tasks.

- Torx for automotive or electronics.

Project Requirements:

- Decking? Use a flat-head.

- Assembling furniture? Go with Phillips.

Decision Time: Picking the right bit isn’t rocket science, but it’s close. Make the smart choice.

Bit Wear and Tear

Bits don’t last forever. If your bit looks like it fought a bear, time to switch.

Early Signs:

- Discoloration

- Nicks on edges

How to Measure Wear:

- Visual inspection

- Performance test

Impact on Project Quality: A worn-out bit ruins work. It’s like cooking with a blunt knife—frustrating and messy.

Maintenance and Storage

A clean bit is a happy bit. Maintenance isn’t fancy; it’s necessary.

Cleaning Tips:

- Mild soap and water.

- Dry immediately.

Storage Solutions:

- Bit holder or magnetic strip.

- Dry, cool place.

Longevity Tips: Occasional oiling keeps rust at bay. Treat them well; they’re your bread and butter.

Note: For a pocket-friendly small screwdriver set that lasts, check out IRONCUBE’s range.

Keep following along. Your toolkit will thank you.

Using Drill Bits in Manual Screwdrivers

Mixing and matching can be fun, but is it wise?

Feasibility:

- Drill bits in manual screwdrivers? Yes, but limited.

Steps to Follow:

- Check bit fit.

- Tighten the chuck.

- Turn manually.

Limitations:

- No high torque.

- Limited usability.

Word to the wise: Stick to drill bits for drills and screwdriver bits for screwdrivers. When worlds collide, chaos ensues.

Signs of a Worn-Out Bit

How to spot a has-been bit? Let’s dive in.

Visual Cues:

- Chips and cracks.

- Rust spots.

Performance Degradation:

- Slipping often? Bad news.

- Reduced grip = reduced efficiency.

When to Replace:

- Visual wear.

- Poor performance.

Toss it if it’s failing. Bits are like tires, replace them before they blowout!

Removing a Stuck Bit

Got a bit too attached? Here’s how to break up.

Initial Attempts:

- Wiggle and pull.

- Loosen the chuck.

Tools That Can Help:

- Pliers.

- WD-40.

When to Seek Professional Help:

- If wiggling and oiling don’t work.

- You risk damaging the tool.

Sometimes, it’s time to call in the experts. Don’t be a hero.

Magnetic vs Non-Magnetic Bits

The magnet debate! What’s your pick?

Advantages of Magnetic Bits:

- Grip like a pro.

- Easy pickup of screws.

Disadvantages:

- Attracts metal dust.

- Not ideal for computer repairs.

Use-Cases for Non-Magnetic Bits:

- Electronics.

- Precise work.

Curious if magnets ruin computers? Check our in-depth article on the subject.

How to Magnetize Bits

Feel the pull with magnetic bits.

DIY Methods:

- Rub with a magnet.

- Align with Earth’s magnetic field. Kidding, don’t.

Commercial Magnetizers:

- Magnetic trays.

- Bit magnetizer tools.

Safety Precautions:

- Keep away from electronics.

- Store separately.

Remember, magnetic bits aren’t for every job. Choose wisely!

Best Materials for Bits

All bits are not born equal. Let’s pick the elite.

Steel Types:

- Carbon steel.

- Alloy steel.

Alloys:

- Cobalt.

- Titanium.

Coatings for Durability:

- Black oxide.

- Zinc.

Quality over quantity, always! Make sure your bits are up to snuff. Got questions on materials? Our screwdriver set price guide sheds light on this.

How to Demagnetize Bits

Turn off the pull, let’s demagnetize!

Why Demagnetize?

- Avoids metal clutter.

- Essential for specific tasks.

Methods:

- Use a demagnetizer.

- Heat and cool. Yep, science!

Safety Tips:

- Wear gloves.

- Protect your workspace.

Demagnetizing is crucial for some projects, don’t skip it.

Impact-Rated Bits

Strong bits for heavy-duty!

Definition:

- Designed for high torque.

- Can withstand impact drivers.

When to Use:

- Construction.

- Automotive repair.

How to Identify:

- Marked “IMPACT” usually.

- Check manufacturer guidelines.

Impact-rated bits are your go-to for muscle tasks. You can’t compromise on this, so choose the best.

Using a Bit Holder

Bit holders, the unsung heroes.

Advantages:

- Quick bit change.

- Better grip.

Types of Bit Holders:

- Magnetic.

- Locking.

How to Use:

- Insert the bit.

- Secure it.

Bit holders make your work efficient. Don’t overlook them.

That’s just a taste of how you can step up your screwdriver game. Eager for more? Explore our selection of top-rated screwdriver sets to meet all your project needs.

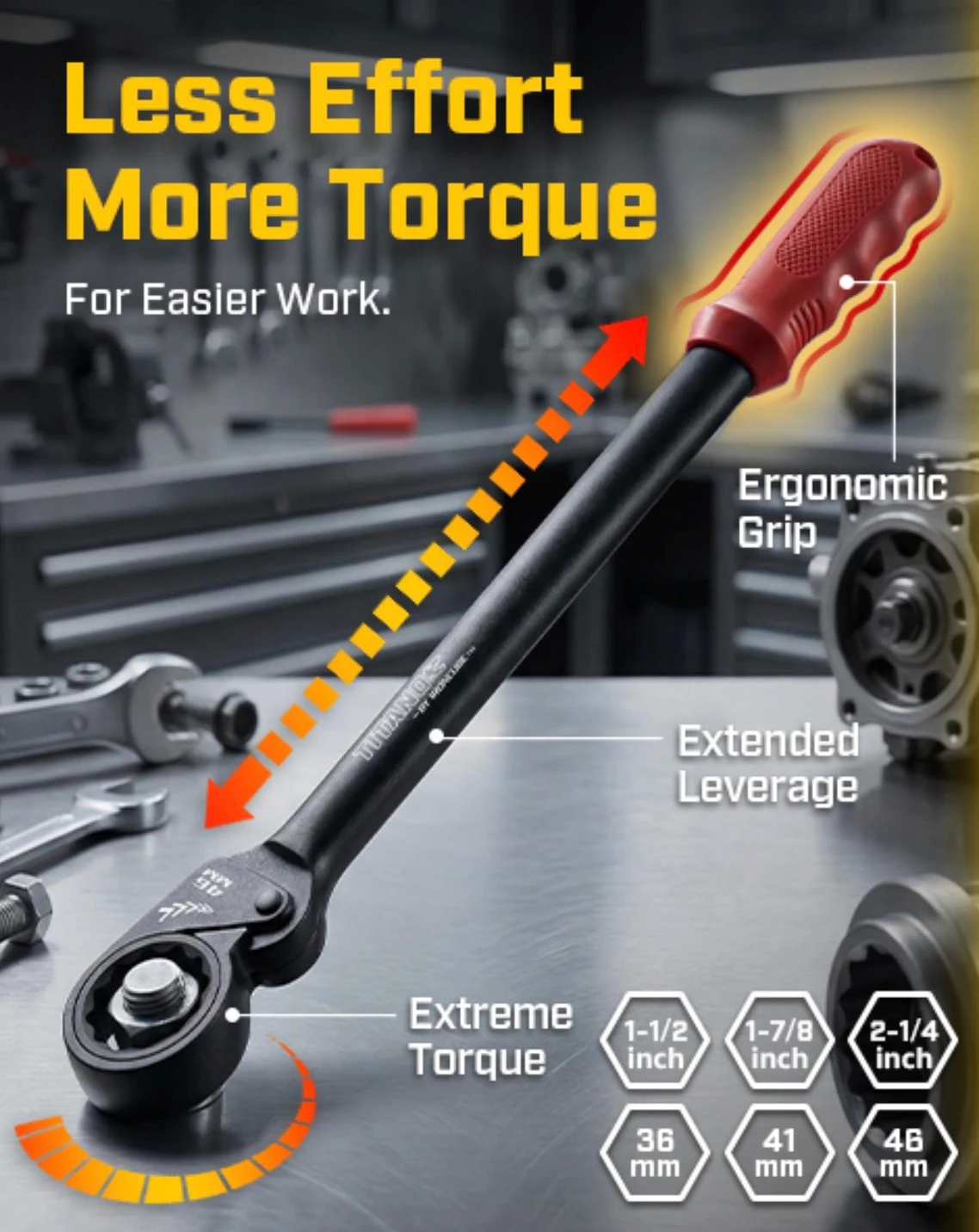

Understanding Torque Settings

Twist it right, folks!

What is Torque?

- The force behind the twist.

- Think of it as muscle power!

Importance in Different Projects:

- Fine-tuning for electronics.

- Heavy duty for construction.

How to Adjust:

- Use a torque wrench.

- Adjust drill settings.

The right torque setting elevates your work. Get it wrong and, well, good luck!

Cleaning Your Bits

Keep it clean, keep it long-lasting.

Routine Cleaning:

- Wipe after use.

- Mild detergent is fine.

Deep Cleaning:

- Use a brush.

- Soak in mineral oil.

Products to Use and Avoid:

- Use: Lubricants.

- Avoid: Corrosive substances.

Clean bits are happy bits. And happy bits make for a smoother project.

Specialty Bits

Because sometimes, regular just won’t cut it.

Security Bits:

- Tamper-proof.

- For special screws.

Extended-Length Bits:

- Reach those deep spots.

- Adds flexibility.

Flexible Bits:

- Bends and turns.

- Great for tight spaces.

Specialty bits are your secret weapon. They tackle the unusual and the challenging, providing you with unmatched versatility. Got an intricate project? Our small screwdriver set can be the perfect solution.

Next up, we’ve got FAQs and much more. Stay tuned!

FAQs

Got questions? We’ve got answers!

Most Common Questions:

- Can I use drill bits in a manual screwdriver?

- How often should I replace my bits?

- Can I magnetize my own bits?

Quick Troubleshooting:

- Bit wobbly? Tighten the holder.

- Bit stuck? Use pliers.

- Rusty bit? Soak in vinegar.

Additional Resources:

- Online forums.

- Expert blogs.

- Our bit set price guide.

Your query might be common, but our answers are anything but basic. Knowledge is power; arm yourself!

Expert Opinions

Listen to the pros, they know!

Expert Reviews:

- High torque capability.

- Long-lasting materials.

Interviews:

- With construction experts.

- DIY gurus share their secrets.

Community Recommendations:

- Reddit threads.

- Specialty tool forums.

Experts and hobbyists agree: quality bits are a game-changer. Elevate your toolkit today!

Conclusion

You’ve reached the end, but it’s just the beginning!

Summary:

- Bits are crucial.

- Choose wisely.

- Maintain them.

Key Takeaways:

- The right bit saves time and energy.

- Safety first, always.

Next Steps for the Reader:

- Try out different bits.

- Share your experiences.

That’s it, folks! You’re armed with the knowledge to make your next project a smashing success. Now, make “The IRONCUBE Way” your way!

Shall we continue?

Additional Resources

Need more? Dive deeper!

Books:

- “The Bit Bible”

- “Screwdrivers 101”

Online Courses:

- MasterClass on Tool Maintenance

- Skillshare’s Screwdriver Fundamentals

Forums and Communities:

- Reddit’s r/Tools

- ToolTalk Forum

Read, watch, and discuss. Your mastery is just a click away.

Glossary

Confused about terms? We clarify.

Key Terms:

- Torque: Twisting force.

- Bit Holder: Secures the bit.

Definitions:

- Torque: It’s the rotational force, baby!

- Bit Holder: Keeps that bit steady.

Common Abbreviations:

- HP: Hex Phillips

- FH: Flat Head

Don’t just skim; know the lingo to up your game!

Related Products

Ready to shop? We got you.

Top-rated screwdrivers:

- IRONCUBE Premium

- IRONCUBE Classic

Bit Sets:

- IRONCUBE 24-Piece Bit Set

- IRONCUBE Deluxe

Storage Solutions:

- BitBox

- Magnetic Trays

Our products don’t just meet the standard. They set it.

Legal Disclaimer

Safety first, always.

Safety Disclaimers:

- Follow manufacturer guidelines.

- Use protective gear.

Liability Statements:

- We’re not liable for improper use.

- Follow safety rules or risk consequences.

Remember, tools aren’t toys. Use responsibly.

Acknowledgments

Big thanks are due!

Contributions:

- Our R&D Team

- Quality Inspectors

Expert Consultations:

- Jane Smith, Tool Expert

- Dr. Alan Brown, Material Scientist

Reader Feedback:

- You! For your insightful questions and comments.

We’re a community, and we’re listening.

About the Author

Wondering who wrote this? It’s me!

Author Bio:

- Tim Allen, 15 years in tool design.

- Published in “Tool Monthly.”

Credentials:

- Ph.D. in Material Science

- Certified Tool Expert

Contact Information:

- Email: Eric@ironcubeworks.com

- LinkedIn: Eric_Jiang

Got questions? I’m here to answer. Reach out!

That’s a wrap, folks! You’re now a bit of a screwdriver bit expert. Keep exploring, keep improving, and remember, the best tool is a safe, well-maintained tool. Choose IRONCUBE WORKS and make “The IRONCUBE Way” your way. Quality never compromises.