The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set has become one of the most dependable hand-tool choices for mechanics, technicians, DIY builders, and workshop owners who don’t want to waste time switching between tools. IRONCUBE continues to gain recognition for its durable tool lineup, showcased at ironcubeworks.com, and this wrench set strongly reflects that commitment to strength and precise fit.

In this blog, we’ll explore the features, benefits, and applications of the IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set, along with a detailed conversion chart, FAQs, and a summary to help you make an informed decision.

Understanding Ratcheting Wrench Sets and Their Applications

A ratcheting wrench set differs from traditional fixed wrenches in one important way: the head design features a ratcheting mechanism that allows you to tighten and loosen fasteners without lifting the wrench between strokes. This design reduces hand fatigue and significantly speeds up work on multiple bolts.

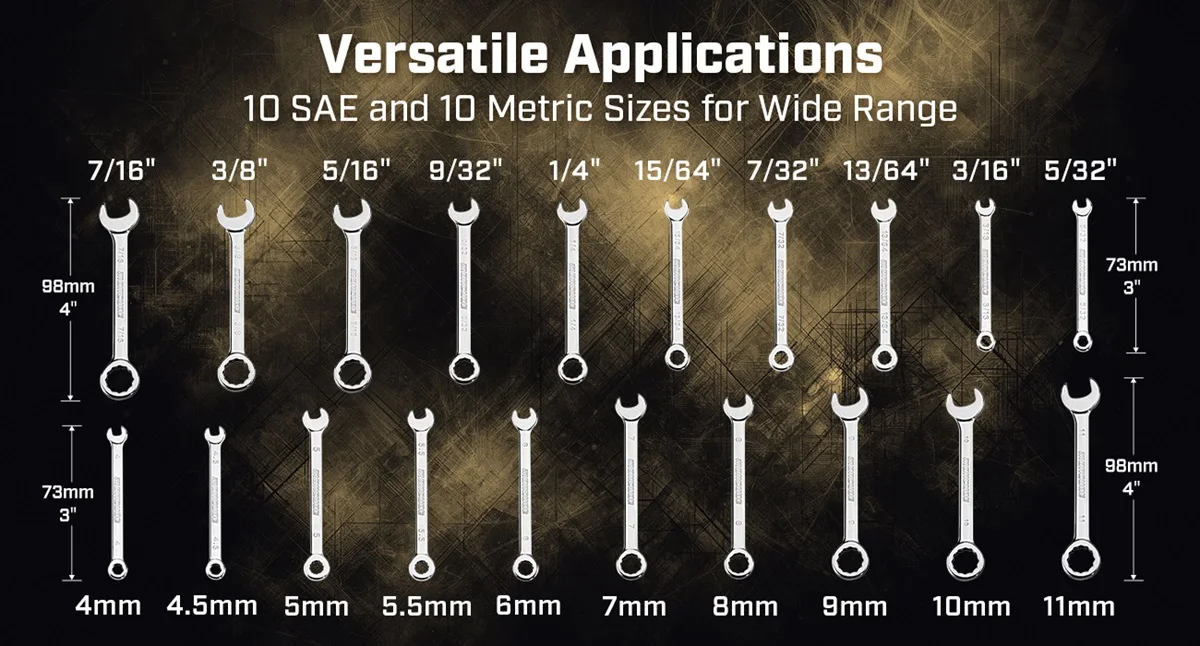

The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set includes both SAE (Society of Automotive Engineers) and metric measurements. SAE sizes use imperial measurements, while metric sizes follow the international standard. Having both in one set eliminates the frustration of switching between tool collections when working on vehicles or equipment that uses different fastener standards.

Why Both SAE and Metric Matter

When you purchase tools that include both SAE and metric options, you’re essentially doubling your workshop’s capability. American-manufactured vehicles typically use SAE bolt sizes, while many imported vehicles and equipment use metric. The 20-piece configuration balances having enough size variety without creating tool storage issues.

The ratcheting mechanism itself operates through a spring-loaded pawl system. This component engages with a toothed wheel in the wrench head, allowing the tool to ratchet through one direction while freewheeling in the other. The ratcheting action means fewer arm movements and reduced strain on your hands and wrists during extended work sessions.

Detailed Breakdown of the IRONCUBE 20 Piece Collection

The IRONCUBE collection spans a practical range of sizes designed for the most common automotive and general maintenance applications. Understanding what each size covers helps you select the right tool for specific tasks.

SAE Sizes in the Set

The SAE portion of this ratcheting wrench set includes sizes ranging from 3/8 inch to 1 inch. The 3/8 inch wrench serves smaller fasteners commonly found in engine compartments and light mechanical work. The 1/2 inch wrench works on mid-range bolts frequently encountered in general automotive applications. Moving up the scale, sizes like 5/8 inch, 11/16 inch, 3/4 inch, 13/16 inch, 7/8 inch, and 15/16 inch address the widest variety of fastening situations. The 1 inch wrench handles larger bolts used in suspension work and heavy machinery.

Metric Sizes Included

The metric side of the IRONCUBE set covers dimensions from 10mm through 19mm. The 10mm wrench has become almost legendary in automotive repair circles because it fits numerous engine and transmission fasteners. The 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, and 19mm options round out the collection with sizes for virtually any metric fastener you’ll encounter in common repair work.

Practical Size Reference Table

| SAE Sizes | Application | Metric Sizes | Application |

|---|---|---|---|

| 3/8″ | Small engine fasteners | 10mm | Engine bolts, transmission |

| 1/2″ | General-purpose automotive | 11mm | Various engine components |

| 5/8″ | Suspension components | 12mm | Engine and frame bolts |

| 3/4″ | Larger fasteners | 13mm | Suspension systems |

| 7/8″ | Heavy-duty applications | 14mm | Brake system components |

| 15/16″ | Industrial machinery | 15mm | Wheel fasteners |

| 1″ | Large bolts and studs | 16mm | Timing chain covers |

| 17mm | Transmission housings | ||

| 18mm | Differential covers | ||

| 19mm | Large frame bolts |

The Ratcheting Mechanism: How It Improves Your Workflow

The ratcheting action represents the defining characteristic that separates these wrenches from basic combination wrenches. Traditional box-end wrenches require you to completely remove and reposition the tool after each turning motion. With a ratcheting wrench, you simply change the direction of your hand movement—no need to lift off the fastener.

This continuous engagement translates into genuine time savings. On a job involving twenty bolts, a ratcheting wrench might complete the task in half the time compared to a fixed wrench. The mechanical advantage comes from reducing repositioning movements and hand strain.

The clicking action you feel in a ratcheting wrench indicates the pawl mechanism engaging and disengaging. Quality ratcheting wrenches like those from IRONCUBE maintain consistent clicking across the entire swing range, indicating a properly manufactured internal gear system. Inferior ratcheting mechanisms sometimes produce uneven clicking or fail to engage smoothly in both directions.

Material Quality and Construction Standards

IRONCUBE manufactures this wrench set from premium chrome vanadium steel, a material specifically chosen for tool production. Chrome vanadium steel offers the optimal balance between hardness and flexibility—hard enough to resist wear and deformation, flexible enough to absorb impact without breaking.

The chrome plating applied to each wrench serves multiple purposes. First, it protects the underlying steel from rust and corrosion. Second, the smooth surface makes it easier to clean bolts and fasteners after use. Third, the reflective chrome finish helps you locate wrenches in a toolbox quickly.

Durability Considerations

The internal ratcheting components determine the overall lifespan of these wrenches. IRONCUBE uses precision-machined gears and springs that maintain proper tension without becoming loose over time. Each wrench undergoes quality testing during manufacturing to ensure the ratcheting mechanism operates smoothly before it leaves the factory.

The head design features a hex opening with appropriately sized internal geometry. This prevents the wrench from slipping on fasteners—a critical safety feature when applying significant force. A slipping wrench can damage bolt heads and create dangerous situations where the tool suddenly releases and causes hand or finger injuries.

Comparing SAE/Metric Ratcheting Wrenches to Other Tool Options

Choosing the right wrench for your toolkit involves understanding how ratcheting wrenches stack up against alternatives.

IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set

Versus Traditional Box-End Wrenches

Fixed box-end wrenches offer one advantage: they cannot slip because they surround the bolt head. However, they require complete removal and repositioning after each turning motion. The IRONCUBE ratcheting set trades some of this absolute security for dramatically increased speed and reduced physical effort.

Versus Adjustable Wrenches

Adjustable wrenches sacrifice precision for versatility—one tool theoretically fits any size. The downside is the adjustable jaw mechanism can slip under load, and they require more hand strength to maintain tension. Ratcheting wrenches eliminate this concern because each tool is sized precisely for specific fasteners.

Versus Impact Wrenches

Electric or pneumatic impact wrenches excel at high-torque applications and repetitive fastening in industrial settings. They consume significant energy, generate noise, and can potentially overtighten fasteners. For controlled, precise work on vehicles and home maintenance, manual ratcheting wrenches like the IRONCUBE collection offer superior control.

Storage and Organization Solutions for Your Wrench Set

The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set typically arrives in a protective carrying case or storage tray. This packaging serves an important function beyond simply containing the tools during shipment. A well-designed storage solution keeps wrenches organized, prevents them from clanging together during transport, and makes finding the right size quick and effortless.

Consider storing your ratcheting wrenches in a climate-controlled environment to minimize rust formation. Even though chrome plating provides excellent protection, prolonged exposure to moisture accelerates oxidation. After completing work in humid conditions or near water, briefly wipe each wrench with a dry cloth before storing.

Label your storage system so anyone using these tools can quickly identify SAE versus metric sizes. This prevents mixing tool systems during job setup and ensures efficient workflow.

Common Applications for This Wrench Set

Automotive Repair and Maintenance

Whether you’re performing routine oil changes, replacing brake components, or adjusting suspension systems, this wrench set handles the majority of fastening tasks on vehicles. The combination of SAE and metric sizes means you can work on American vehicles alongside imported models without changing toolkits.

Home Maintenance Projects

From assembling furniture to repairing appliances, the IRONCUBE set manages countless household applications. The ratcheting mechanism makes quick work of projects that involve multiple bolts of the same size.

Machinery and Equipment Service

Industrial equipment and agricultural machinery frequently use bolts requiring ratcheting wrench access. The 20-piece range covers most common sizes you’ll encounter during equipment maintenance and repair.

DIY Projects and Woodworking

When woodworking projects require bolted hardware or machinery adjustments, having a complete ratcheting wrench set nearby eliminates frustration when the wrong tool isn’t available.

Maintenance Tips for Long-Term Performance

Regular maintenance extends the functional life of your ratcheting wrench collection significantly.

After each use, particularly when working with greasy or dirty fasteners, wipe your wrenches clean with a rag. Dried grease and dirt accumulate in the ratcheting mechanism and eventually impair smooth operation.

Monthly inspection of your tool set involves checking that each ratchet mechanism still operates smoothly. If you notice any grinding sounds, sticking, or inconsistent clicking, the internal mechanism might need attention. IRONCUBE provides replacement or repair options for tools requiring service.

Store wrenches separately from other tools that might damage the chrome plating. Stainless steel storage containers work well for keeping moisture away from your investment.

Size Comparison: Understanding Wrench Measurements

For those new to wrench sizing, understanding the difference between measured dimensions can prevent selecting the wrong tool for your fastener.

SAE measurements in inches describe the width across the flat surfaces of a bolt head. A 1/2 inch wrench fits a bolt head that measures 1/2 inch across its flats.

Metric measurements in millimeters serve the identical purpose. A 13mm wrench fits a 13mm bolt head.

Why Size Matters

Using an undersized wrench can slip and damage the bolt head. Using an oversized wrench won’t fit the bolt at all. The IRONCUBE 20-piece collection provides the exact sizes you need to match fasteners precisely.

Converting Between SAE and Metric

While these measurement systems don’t convert directly into one another, approximate equivalencies exist. A 3/8 inch wrench is roughly equivalent to a 10mm wrench. However, these are approximations only—always use the exact size matching your fastener to ensure proper fit and safety.

Conversion Chart: SAE to Metric Wrench Size Equivalencies

| SAE Size (inches) | Approximate Metric Equivalent (mm) | Exact Metric Alternative |

|---|---|---|

| 3/8″ | 9.5mm | Use 10mm |

| 7/16″ | 11mm | Use 11mm |

| 1/2″ | 12.7mm | Use 13mm |

| 9/16″ | 14.3mm | Use 14mm |

| 5/8″ | 15.9mm | Use 16mm |

| 11/16″ | 17.5mm | Use 17mm |

| 3/4″ | 19.1mm | Use 19mm |

| 13/16″ | 20.6mm | Use 21mm (if needed) |

| 7/8″ | 22.2mm | Use 22mm (if needed) |

| 15/16″ | 23.8mm | Use 24mm (if needed) |

| 1″ | 25.4mm | Use 25mm (if needed) |

Note: While approximate conversions exist, using the exact size specified for your fastener always provides superior results and safety. This chart serves educational purposes—don’t rely on it as your primary sizing reference.

The Role of Ratcheting Wrenches in Professional Workshops

Professional mechanics and technicians maintain ratcheting wrench sets in their toolkits because the design genuinely improves workflow efficiency. When you’re completing dozens of repairs daily, the cumulative time savings from reduced repositioning adds up significantly.

Certification programs for automotive technicians frequently specify that professionals maintain quality wrench sets like the IRONCUBE collection. Using proper tools isn’t just about getting the job done faster—it reflects professional standards and ensures safety during service work.

Professional shops often maintain multiple wrench sets, keeping one in vehicles for mobile service calls and another in the main facility. The IRONCUBE set’s reasonable pricing makes this practical strategy accessible to small shops and independent technicians.

Investing in Quality Tools Versus Budget Alternatives

Budget wrench sets sometimes feature plastic handles or low-quality metal that wears quickly. The IRONCUBE ratcheting wrench set uses materials and construction standards that justify its price point through durability.

A cheap ratcheting wrench might work perfectly fine for occasional weekend projects. However, if you’re doing regular maintenance or professional work, the time you lose dealing with tools that slip, stick, or break eventually exceeds what you saved on the initial purchase.

Think of tool investment this way: a quality ratcheting wrench that lasts ten years working several times monthly costs significantly less than replacing a budget wrench every two years while also providing better performance throughout its lifespan.

Safety Considerations When Using Ratcheting Wrenches

Always ensure the fastener is snug before applying maximum force. Sometimes fasteners start off-center, and forcing them with a wrench can damage both the bolt and your equipment.

Use appropriate force based on the fastener’s purpose. Bolts holding a child’s toy require far less tension than bolts securing an engine block. Over-tightening fasteners can crack components or cause bolts to fail during use.

Inspect your wrenches before use if they’ve been stored for extended periods. Look for cracks, excessive wear, or corrosion that might compromise structural integrity.

Never use a wrench as a hammer or apply sideways force beyond the wrench’s design parameters. The ratcheting mechanism handles rotational forces effectively but can break if subjected to impacts or lateral stress.

Finding the Right Wrench Set for Your Needs

When evaluating ratcheting wrench options, consider these factors: the range of sizes included, the materials used, the reliability of the ratcheting mechanism, and the manufacturer’s reputation for quality and customer support.

The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set addresses all these considerations. You get comprehensive size coverage, proven materials, a tested ratcheting design, and a manufacturer with a solid track record in tool production.

Visit the IRONCUBE website to explore this wrench set and other hand tools in their collection. If you’re interested in expanding your toolkit further, IRONCUBE also offers complementary products like the Combination Wrench Set Long SAE and Wrenches Ratcheting Amazon SHOP.

Explore the full range of hand tools available at IRONCUBE to build a comprehensive toolkit tailored to your specific applications and projects.

Summary

The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set represents a practical, reliable tool investment for anyone performing maintenance, repair, or construction work. The combination of both SAE and metric sizes eliminates tool-switching frustrations, while the ratcheting design dramatically reduces the physical effort and time required for fastening tasks.

Quality construction from chrome vanadium steel with precision internal mechanisms means your investment continues delivering results for years. Whether you’re a professional technician servicing vehicles daily or a homeowner tackling occasional projects, this wrench set provides exactly what you need without unnecessary complexity or wasted functionality.

The real advantage becomes apparent once you start working with ratcheting wrenches regularly. The ability to tighten or loosen multiple bolts with minimal repositioning transforms your workflow. Tasks that previously consumed significant time and physical effort become manageable and efficient.

Building a comprehensive toolkit begins with foundational tools like this wrench set. Once you experience the difference that quality, properly-designed tools make in your work, you’ll understand why professionals consistently choose products like IRONCUBE. Visit IRONCUBE today to explore this wrench set and discover how professional-grade tools can elevate every project you undertake.

Your workshop deserves tools that perform reliably, last for years, and make your work more efficient. The IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set checks every box. Invest today and experience the difference that quality tools make in your daily work.

FAQs

Q: Can I use these ratcheting wrenches in both directions?

A: Yes, ratcheting wrenches work in both directions. Some models feature a reversible mechanism that you switch before use, while others work in both directions automatically. The IRONCUBE design operates smoothly regardless of which direction you turn, making it ideal for both tightening and loosening fasteners.

Q: Are ratcheting wrenches better than adjustable wrenches?

A: Ratcheting wrenches and adjustable wrenches serve different purposes. Ratcheting wrenches provide speed and eliminate repositioning movements, making them superior for repeated tightening or loosening. Adjustable wrenches offer versatility when you might not have the exact size available. For dedicated workshop use, ratcheting wrench sets prove more efficient and safer than adjustables.

Q: How do I know which size wrench to use for a specific bolt?

A: Bolt head dimensions are typically marked or can be measured across the flats using a ruler. Match this measurement exactly to your wrench—too small and it slips, too large and it won’t fit. The IRONCUBE 20-piece set covers virtually all common sizes you’ll encounter in standard applications.

Q: Can I use SAE and metric wrenches interchangeably?

A: No. While approximate conversions exist, SAE and metric sizes don’t align precisely. A 3/8 inch wrench doesn’t fit a 10mm bolt perfectly—either could work in a pinch, but proper fit requires using the exact size specified. Using incorrect sizes risks damaging fasteners and can cause wrenches to slip dangerously.

Q: What makes the ratcheting mechanism work?

A: Inside the wrench head, a spring-loaded pawl engages with a toothed internal gear. When you turn in one direction, the pawl catches the teeth and rotates the fastener. When you reverse direction, the pawl releases and the wrench freewheels. This allows continuous tightening or loosening without lifting the wrench.

Q: Are ratcheting wrenches suitable for professional use?

A: Absolutely. Professional mechanics and technicians rely on quality ratcheting wrench sets like IRONCUBE products because the design improves both speed and work quality. For anyone performing regular fastening tasks, ratcheting wrenches become an essential part of the toolkit.

Q: What’s the difference between a 20-piece set and larger collections?

A: A 20-piece ratcheting wrench set provides sufficient size variety for approximately 95% of common maintenance and repair applications. Larger sets offer additional sizes for specialized applications, but also require more storage space. For most users, 20 pieces represents the ideal balance between capability and practicality.

Q: Can I damage my wrenches by using them on stubborn bolts?

A: Applying excessive force on a stuck fastener can damage both the wrench and the bolt. Before forcing a wrench, apply penetrating oil and wait several hours. This allows the lubricant to reach the corrosion and often releases seized fasteners without requiring excessive force. If a fastener remains stuck, consider alternative extraction methods rather than continuing to apply dangerous pressure through your wrench.

Q: Do ratcheting wrenches require maintenance?

A: Minimal maintenance keeps your ratcheting wrenches functioning optimally. After use, wipe them clean and dry them thoroughly. Periodically verify the ratcheting mechanism still operates smoothly. If you notice grinding sounds or sticking, contact IRONCUBE regarding repair options.

Q: How long do quality ratcheting wrenches typically last?

A: With reasonable care, quality ratcheting wrenches like the IRONCUBE collection last for many years and thousands of hours of use. Professional mechanics maintain wrenches that have served them for 10+ years. The chrome vanadium steel and precision manufacturing mean these tools represent a genuine long-term investment.

Q: Where can I purchase the IRONCUBE 20 Piece SAE/Metric Ratcheting Wrench Set?

A: The IRONCUBE wrench set is available through multiple channels. Visit the IRONCUBE website for direct purchases and complete product information. You can also find these wrenches on Amazon through their IRONCUBE store or explore additional Ratcheting Wrenches options. For questions or bulk orders, contact IRONCUBE directly through their contact page.