In industrial environments, tools are not chosen for convenience alone. They are selected for strength, reliability, and efficiency under pressure. When technicians face seized bolts, cramped spaces, and long working hours, the right hand tool can make the difference between smooth progress and costly downtime. This is where a ratchet wrench set becomes an essential part of every professional toolkit.

A heavy-duty flex head ratchet wrench set is designed to perform where standard wrenches fall short. From automotive repair bays and manufacturing floors to HVAC installations and industrial maintenance, these tools support faster workflows, safer handling, and consistent torque delivery. In this in-depth guide, we explore why industrial professionals rely on a quality ratchet wrench set, how flex head designs improve performance, and why IronCube Works has become a trusted name in this space.

Why a Ratchet Wrench Set Is Critical in Industrial Work

Industrial tasks demand repeatable precision. Fasteners are often positioned behind components, under machinery, or inside confined assemblies. A traditional wrench requires constant repositioning, which slows work and strains the wrist.

A ratchet wrench set solves this problem by allowing continuous motion without removing the wrench from the fastener. This simple mechanical advantage saves time and energy across hundreds of turns each day. According to studies referenced by industrial ergonomics researchers, ratcheting tools can reduce task completion time by up to 35–40% compared to standard hand wrenches when working in tight spaces.

In heavy-use environments, that time savings compounds quickly. Over a week or a month, it can mean hours of labor saved and reduced physical fatigue.

What Makes a Flex Head Ratchet Wrench Set Different

A flex head ratchet wrench set adds another layer of efficiency. The pivoting head allows the wrench to bend and adapt to awkward angles. Instead of forcing your wrist into an uncomfortable position, the tool adjusts to the job.

This design is especially valuable in modern equipment, where compact layouts leave little clearance around bolts. Automotive engine bays, HVAC duct systems, and industrial pump assemblies all benefit from the added reach and flexibility.

IronCube Works explores real-world examples of this advantage in its guide on how a flex head ratchet wrench set saves time on auto repairs, where reduced tool changes and faster access translate into measurable productivity gains.

Flex head designs also reduce slippage. When the wrench aligns more naturally with the fastener, there is less risk of rounding bolt heads or damaging surrounding components.

Features to Look for in a Professional Ratchet Wrench Set

Tooth Count and Arc Swing

The ratcheting mechanism’s tooth count determines how small an arc you need to swing the wrench before it engages for the next advancement. Higher tooth counts mean finer increments and better performance in tight spaces. Entry-level tools might feature 32 or 48 teeth, requiring an 11-degree or 7.5-degree swing, respectively. Professional-grade sets often push into the 72-tooth range with a 5-degree swing, and premium models can reach 90 teeth or more.

That said, higher tooth counts don’t automatically mean better tools. The mechanism needs to be engineered to handle the stresses involved without stripping or failing. A well-made 72-tooth ratchet will outperform a cheaply manufactured 90-tooth version every time. Focus on overall build quality and brand reputation rather than chasing the highest numbers on specification sheets.

Material Construction and Durability

Industrial applications demand tools built from premium materials. Chrome vanadium steel has become the industry standard for professional-grade wrenches, offering an excellent balance of strength, hardness, and corrosion resistance. The alloy typically undergoes heat treatment to achieve optimal hardness throughout the working surfaces while maintaining enough flexibility in the handle to prevent brittle fractures under high loads.

Surface treatments add another layer of protection and functionality. Chrome plating serves the dual purpose of corrosion resistance and easy cleaning, as oils and grime wipe off polished chrome more readily than raw steel. Some manufacturers apply additional coatings to handles for improved grip, though the wrench head typically remains polished for accurate fastener engagement. Understanding these material properties helps when comparing different ratchet wrench set options on the market.

Size Range and Organization

A comprehensive ratchet wrench set should cover the fastener sizes you’ll encounter most frequently in your work. Metric sets typically span 8 mm through 19 mm, while SAE versions run from 5/16″ to 3/4″. Some applications require larger sizes, so consider your specific needs before purchasing. The IRONCUBE metric fixed ratcheting wrench set provides excellent coverage for most industrial applications.

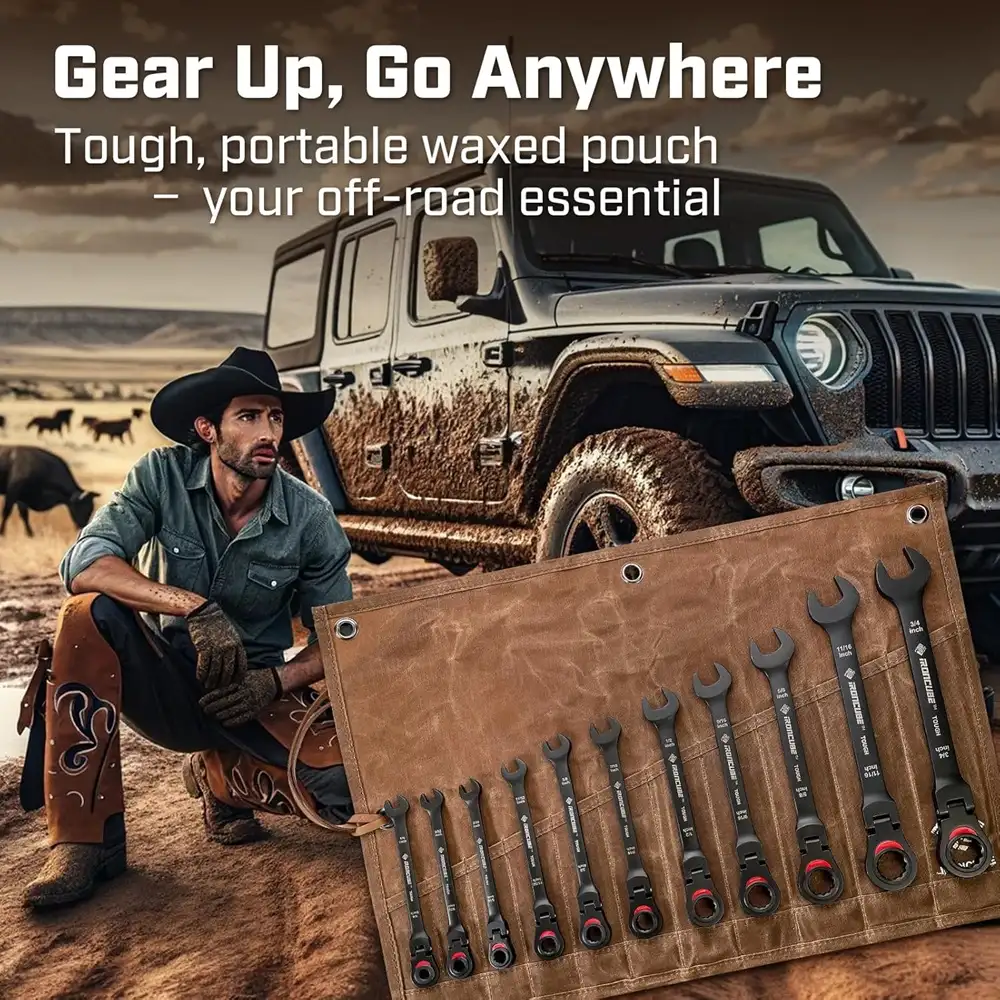

Storage solutions matter more than many buyers initially realize. Loose wrenches banging around in a drawer or toolbox suffer cosmetic damage and can be difficult to locate quickly when time matters. Quality sets include purpose-built storage such as roll-up pouches, rigid cases, or canvas bags that keep tools organized and protected. This organizational element pays dividends in day-to-day efficiency.

Industrial Applications Where Flex Head Wrenches

Automotive and Heavy Equipment Maintenance

Automotive technicians were among the first to embrace flex-head ratcheting wrenches, and the reasons become obvious to anyone who’s spent time under a hood. Modern vehicles pack increasingly complex systems into ever-smaller spaces, creating access challenges that rigid tools simply cannot address. From intake manifold bolts to suspension components, a flex head ratchet wrench set opens up possibilities that would otherwise require time-consuming disassembly of surrounding components.

Heavy equipment presents similar challenges at a larger scale. Excavators, bulldozers, and agricultural machinery feature massive fasteners positioned in cramped engine compartments and undercarriage areas. Field service technicians particularly appreciate flex head tools, as they reduce the need to carry specialized wrenches for specific machines. Understanding how flex head ratchet wrench sets save time on auto repairs can dramatically improve shop throughput.

HVAC and Plumbing Installations

Heating, ventilation, and air conditioning work routinely involves fasteners in overhead locations, inside ductwork, and around refrigerant lines where access is severely limited. Plumbers face comparable challenges when working under sinks, behind fixtures, and in wall cavities. In both trades, the ability to approach fasteners from unconventional angles separates efficient professionals from those who struggle through each job.

The guide to flex head ratchet wrench sets for plumbing and HVAC work provides detailed insights into optimizing tool selection for these demanding applications. Successful tradespeople understand that investing in quality tools ultimately reduces labor time and improves customer satisfaction through faster, more professional work.

Manufacturing and Assembly Lines

Production environments prioritize consistency and speed above almost everything else. Assembly line workers performing repetitive fastening tasks benefit enormously from ergonomic tool designs that reduce fatigue. Maintenance teams keeping production equipment running face constant pressure to minimize downtime, making efficient tools essential rather than optional.

Manufacturing settings also tend to be hard on tools. Exposure to coolants, cutting fluids, and various industrial chemicals tests corrosion resistance, while the sheer volume of use accelerates wear on moving parts. A heavy-duty ratchet wrench set built for industrial use will hold up far better than consumer-grade alternatives under these demanding conditions.

Standard Wrenches and Ratcheting Wrench Sets

Standard combination wrenches still have their place, but their limitations become obvious in repetitive industrial tasks. Each turn requires lifting, repositioning, and re-engaging the wrench.

A ratchet wrench set eliminates that inefficiency. Continuous motion allows technicians to maintain focus and rhythm, which improves accuracy and reduces fatigue. Over long shifts, this ergonomic benefit becomes just as important as speed.

Flex head ratcheting wrenches go further by adapting to the work environment. They reduce the need for extensions, adapters, or secondary tools, simplifying the workflow.

Building Your Professional Toolkit

A flex head ratchet wrench set forms one component of a complete professional toolkit. Complementary tools that extend your capabilities include standard ratchets with socket sets for larger fasteners, torque wrenches for precision tightening, and specialty tools for specific applications.

Don’t overlook supporting equipment like quality screwdriver sets for Phillips, flathead, and specialty fasteners. The best 6-in-1 hex screwdriver sets combine multiple bit sizes into compact, convenient tools that save space in your kit while providing the versatility needed for varied work.

The complete IRONCUBE flex head ratchet wrench set guide outlines how these tools integrate with broader toolkit strategies. When choosing a 4-piece flex head ratchet wrench set or deciding between different configurations, consider your most common tasks and select accordingly.

Where to Purchase Quality Industrial Tools

Reputable suppliers stand behind their products with solid warranties and customer service. The IRONCUBE Amazon storefront offers convenient access to their complete product line with the purchase protection Amazon provides. For those who prefer shopping by category, the wrench collection page showcases available ratchet wrench set options with detailed specifications and customer reviews.

The broader IRONCUBE brand page displays its full catalog of professional hand tools. Whether you’re outfitting a new shop or replacing worn equipment, exploring the complete range helps identify tools that complement your existing collection.

For personalized recommendations or questions about specific applications, the IRONCUBE contact page connects you directly with knowledgeable representatives who can guide your purchasing decisions based on your particular needs and budget.

Summary

A heavy-duty flex head ratchet wrench set represents an essential investment for any professional working in industrial, automotive, HVAC, or manufacturing environments. The combination of ratcheting efficiency and flex head versatility addresses access challenges that would otherwise require multiple specialty tools or time-consuming workarounds.

When selecting your set, prioritize build quality over feature count. Chrome vanadium construction, precision-machined components, and robust flex head mechanisms outlast cheaper alternatives many times over. Factor in storage solutions that protect your investment and keep tools organized for efficient retrieval.

Proper usage and maintenance practices extend tool life and protect user safety. Regular cleaning, appropriate lubrication, and periodic inspection prevent problems before they affect your work. Avoid exceeding torque limits that can damage the ratcheting mechanism.

Quality professional tools pay for themselves through improved efficiency, reduced fatigue, and reliable performance when you need it most. Investing in a well-engineered ratchet wrench set means investing in your capability to tackle demanding jobs with confidence and professionalism.

FAQs

1. What makes a flex head ratchet wrench set different from a standard wrench?

A flex head ratchet wrench set features a pivoting head that allows access to tight spaces, unlike standard wrenches, which have fixed heads.

2. Can I use a ratchet wrench set for automotive repairs?

Absolutely! A ratchet wrench set is ideal for automotive repairs, offering the flexibility and durability needed for tasks like engine maintenance and brake work.

3. How do I maintain my ratchet wrench set?

Regularly clean your tools with a soft cloth and lubricate the ratcheting mechanism to ensure smooth operation.

4. What sizes are included in a typical ratchet wrench set?

Sets vary, but most include sizes ranging from 6mm to 19mm. IronCubeWorks offers comprehensive sets with up to 12 pieces.

5. Is a flex head ratchet wrench set suitable for industrial use?

Yes, a heavy-duty flex head ratchet wrench set is designed to withstand the rigors of industrial environments, making it a reliable choice for professionals.