Modern agriculture depends on machines that work hard every single day. From tractors and harvesters to irrigation systems and livestock equipment, farms run on hardware that must stay reliable. That is why having the right hand tools is not a luxury—it is a necessity. A Jumbo Ratcheting Wrench Set has become one of the most valuable tool investments for farmers, mechanics, and agricultural contractors who regularly handle large fasteners under demanding conditions.

If you manage equipment on a working farm, you already know how frustrating it can be to struggle with stubborn bolts, awkward angles, and limited access points. Traditional spanners often waste time and energy. By contrast, a high-quality jumbo ratcheting solution can transform your workflow, saving effort while improving safety and efficiency. This guide explores the best options, real-world benefits, and how to choose the right set for agricultural use.

Throughout this article, you will also find helpful resources and product references from Iron Cube Works, including their growing collection of professional-grade tools at and the dedicated wrench category.

Why Agricultural Work Demands Jumbo Wrenches

Standard wrench sets typically max out around 24mm or 1 inch. Farm equipment regularly uses fasteners ranging from 1-1/2 inches to 2-7/8 inches. Trying to work on a John Deere combine with residential garage tools is like trying to mow an acre with scissors. It’s technically possible, but you’ll waste hours and probably injure yourself.

Agricultural fasteners face extreme conditions. They endure constant vibration from diesel engines. They sit exposed to rain, mud, and temperature swings. Over time, corrosion and stress make these bolts incredibly stubborn to remove. A jumbo ratcheting wrench set provides the extended reach and mechanical advantage necessary to break loose even the most seized fasteners.

The ratcheting mechanism matters more than many farmers realize. Traditional box-end wrenches require you to completely lift and reposition the tool after each partial turn. In tight spaces around hydraulic lines or near engine blocks, this repositioning becomes nearly impossible. A ratcheting design allows continuous motion without removing the wrench from the fastener. This single feature can cut repair time in half.

What Is a Jumbo Ratcheting Wrench Set?

A wrench, as defined by the general tool classification, is a hand tool used to provide grip and mechanical advantage in applying torque to turn objects such as nuts and bolts.

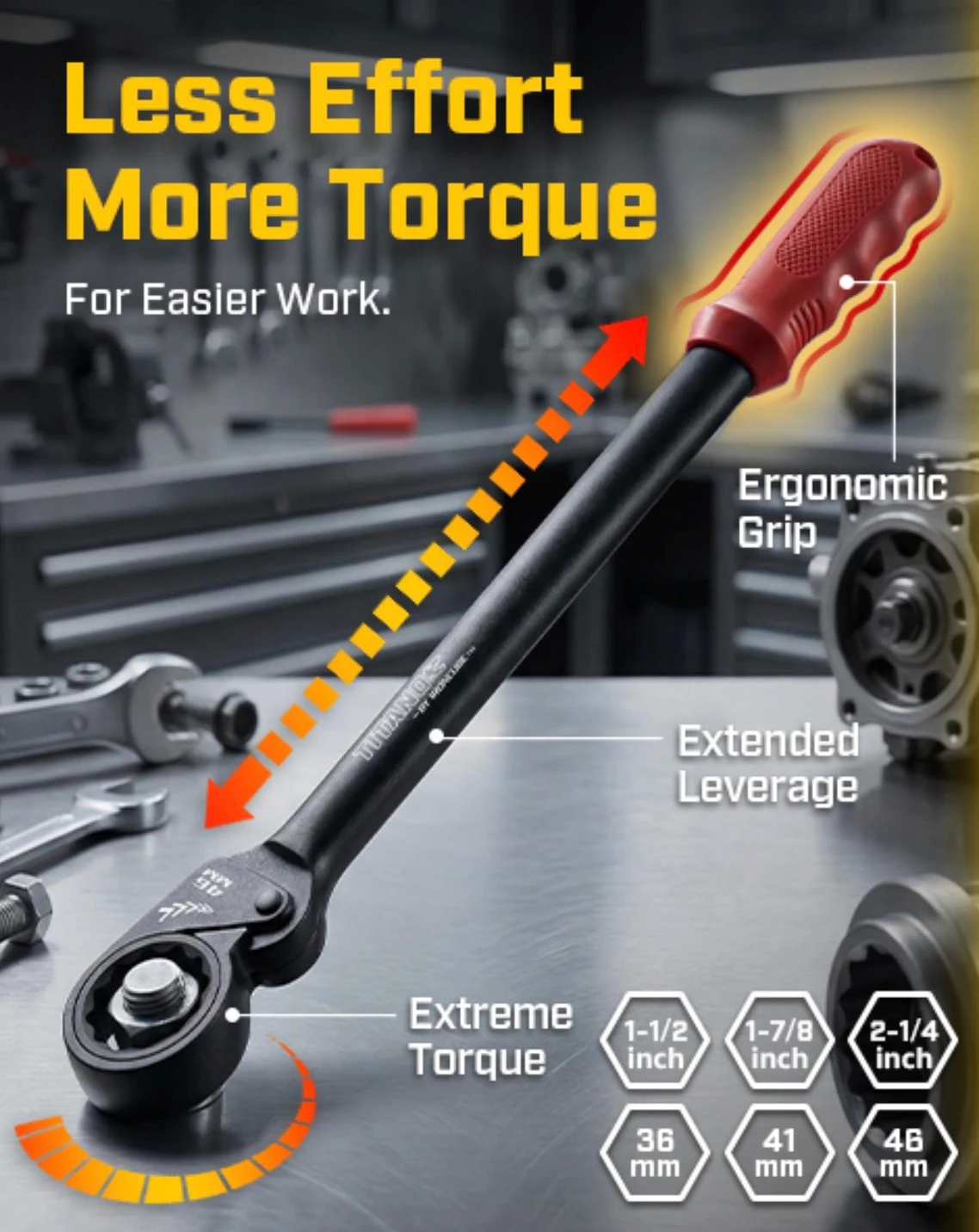

A Jumbo Ratcheting Wrench Set builds on that principle but introduces two critical upgrades:

First, the size range is significantly larger than standard sets, typically covering fasteners from around 30mm up to 80mm or more.

Second, the ratcheting mechanism allows continuous tightening or loosening without removing and repositioning the tool after each turn.

For agricultural professionals, this means faster repairs in the field, reduced hand fatigue, and far better access to bolts located in confined or awkward positions.

Features to Look For in a Jumbo Ratcheting Wrench Set

Not every jumbo wrench set deserves a place in your equipment barn. Cheaply made tools will round off bolt heads, slip under torque, or break entirely when you need them most. Here’s what separates professional-grade tools from hardware store disappointments.

Material Quality and Construction

Chrome vanadium steel remains the industry standard for professional wrenches. This alloy delivers excellent strength-to-weight ratios and resists corrosion better than plain carbon steel. Premium manufacturers like IRONCUBE use drop-forged construction methods that align the steel’s grain structure for maximum durability.

The finish matters for longevity. A good chrome plating protects against rust while making the tool easier to clean after a greasy repair job. Satin finishes reduce glare when working in direct sunlight, which field repairs often require.

Ratcheting Mechanism Design

The tooth count in a ratcheting wrench determines how much you can turn the fastener in tight spaces. Budget wrenches might offer 12-tooth mechanisms requiring 30 degrees of swing arc. Professional-grade tools feature 72-tooth or 90-tooth mechanisms that work in arcs as small as 4 degrees.

For agricultural applications, look for wrenches with reversible ratchets. You’ll switch between loosening and tightening constantly during equipment maintenance. A convenient switch mechanism saves time and frustration compared to flipping the entire wrench over.

Size Range Coverage

A truly useful jumbo ratcheting wrench set should cover the fastener sizes most common on farm equipment. At minimum, you want coverage from 1-1/4 inches through 2 inches in SAE measurements, or 32mm through 50mm in metric.

Some manufacturers offer individual friction wrenches for specific sizes that see heavy use. The 1-7/8 inch size appears constantly on agricultural hydraulic fittings, making dedicated tools for this size a smart investment.

Handle Length and Leverage

Longer handles provide more torque for the same physical effort. However, agricultural work often happens in cramped spaces where a 24-inch handle simply won’t fit. The best jumbo ratcheting wrench set options balance leverage against maneuverability.

Offset handles help clear obstacles while maintaining grip angle. A 15-degree offset lets you work over protective shields and guards without skinning your knuckles on surrounding components.

Top Jumbo Ratcheting Wrench Set Options for Agriculture

After examining dozens of options, these sets consistently deliver the performance agricultural professionals demand. Each offers different advantages depending on your specific equipment and budget.

Premium Industrial Sets

For professional agricultural mechanics who repair equipment daily, investing in industrial-grade tools pays dividends over years of use. These sets typically include lifetime warranties and replacement programs that cover normal wear.

The IRONCUBE heavy-duty flex head ratchet wrench set represents this category well. Flex head designs allow the wrench to pivot and reach fasteners at odd angles. When you’re lying under a grain cart trying to access a bolt hidden behind the axle, this flexibility becomes essential.

Industrial sets often include storage solutions that keep tools organized and portable. Canvas rolls protect chrome finishes during transport between job sites. Wall-mounted racks keep everything visible and accessible in shop environments.

Mid-Range Options for Farm Owners

Farmers who perform their own routine maintenance need reliable tools without the premium price of professional sets. Mid-range jumbo ratcheting wrench set options deliver solid performance for occasional use.

These sets typically feature 48-tooth or 60-tooth ratcheting mechanisms. While not quite as refined as premium options in tight spaces, they handle most agricultural repairs competently. Chrome vanadium construction remains standard at this price point, though finishing quality may vary.

Consider sets that include both SAE and metric sizes. Modern farm equipment increasingly uses metric fasteners, especially on components sourced from European manufacturers. Having both measurement systems available prevents frustrating trips to town during critical repairs.

Budget-Conscious Alternatives

Occasional users might consider entry-level sets for emergency repairs or infrequent maintenance tasks. These tools work adequately for light-duty applications but may struggle with seriously seized fasteners.

Budget sets often sacrifice tooth count for affordability. A 12-tooth mechanism requires significant swing arc, making work in tight spaces difficult. For simple tasks like adjusting implement settings or replacing worn pins, this limitation rarely causes problems.

If budget constraints are significant, consider purchasing individual wrenches in your most-used sizes rather than complete sets. This approach lets you invest in quality for the sizes you actually need while skipping rarely-used options.

Maintenance Tips for Your Jumbo Ratcheting Wrench Set

To ensure your Jumbo Ratcheting Wrench Set provides years of reliable service, proper maintenance is essential. Agricultural environments can be particularly harsh on tools, with dirt, moisture, and chemicals all taking their toll.

Cleaning Procedures

After each use, wipe your wrenches clean with a rag to remove dirt, grease, and moisture. For more thorough cleaning, use a degreaser and a stiff brush to remove stubborn grime from the ratcheting mechanism. Pay special attention to the moving parts, as accumulated debris can impair the ratcheting action.

Once clean, dry the tools thoroughly to prevent rust. A light coat of machine oil on the metal surfaces provides additional protection against corrosion, especially if you store your tools in a damp environment.

Lubrication Needs

The ratcheting mechanism requires periodic lubrication to maintain smooth operation. Apply a small amount of penetrating oil to the mechanism every few months, or more frequently if you use your tools in particularly dirty or dusty conditions. Work the mechanism back and forth to distribute the oil evenly, then wipe away any excess to prevent attracting dirt.

Proper Storage

Store your Jumbo Ratcheting Wrench Set in a dry location to prevent rust and corrosion. If your set came with a storage case, use it to protect the tools from impact damage and keep them organized. For added protection, consider placing moisture-absorbing desiccant packets in your toolbox or storage case.

When to Replace

Even the highest quality tools eventually wear out. Signs that it’s time to replace your wrench set include:

- Slipping or skipping in the ratcheting mechanism

- Excessive play or looseness in the joint

- Corrosion that cannot be removed

- Cracks or other damage to the metal

Investing in a new set before a tool fails during a critical repair can save you significant time and frustration.

How to Choose the Right Jumbo Ratcheting Wrench Set for Your Farm

Selecting the perfect Jumbo Ratcheting Wrench Set for your agricultural operation requires careful consideration of your specific needs and circumstances.

Assessing Your Equipment

Begin by inventorying the machinery you maintain regularly. Check the sizes of the largest fasteners on your tractors, combines, irrigation systems, and other equipment. This will help you determine the maximum size wrench you need and ensure your new set covers all your requirements.

If you primarily work with standard farm equipment, a set ranging from 1 inch to 2 inches will likely suffice. However, if you maintain specialized or older machinery, you may need larger sizes or specific wrench profiles.

Evaluating Your Work Environment

Consider where you’ll be using your tools. If you frequently work in tight spaces, a set with flexible heads or slim profiles might be worth the extra investment. For outdoor work in various weather conditions, prioritize corrosion resistance and ergonomic grips that remain comfortable even in wet or cold conditions.

Budget Considerations

While it’s tempting to opt for the least expensive option, remember that tools are an investment in your productivity. A higher-quality Jumbo Ratcheting Wrench Set will typically last longer and perform better, ultimately saving you money through reduced downtime and fewer replacements.

That said, there’s no need to purchase the most expensive set if your needs are modest. Consider your usage frequency and the criticality of your equipment when determining how much to invest in your tools.

Future-Proofing Your Investment

Agricultural technology continues to evolve, with new equipment featuring different fastener types and sizes. When selecting a wrench set, consider choosing one with a slightly broader size range than you currently need. This foresight can prevent the need for additional purchases as you upgrade or expand your machinery fleet.

Where to Buy Quality Jumbo Ratcheting Wrench Sets

Finding quality tools requires looking beyond big-box hardware stores. While convenient, these retailers often prioritize price over quality in their tool selections. Agricultural professionals need suppliers who understand demanding applications.

Specialty tool manufacturers like IRONCUBE Works focus exclusively on professional-grade hand tools. Their complete wrench selection includes options specifically designed for heavy equipment maintenance. Working directly with manufacturers often provides better warranty support and access to replacement parts.

Industrial supply distributors serve agricultural markets with commercial-grade tools. Companies like Grainger, Fastenal, and MSC Industrial carry premium brands that meet professional standards. Prices run higher than consumer retailers, but tool quality justifies the investment.

Online marketplaces offer convenient access to both premium and budget options. The IRONCUBE Amazon storefront provides easy purchasing with reliable shipping. Customer reviews help identify which options actually perform as advertised.

Used tool markets occasionally offer professional-grade sets at reduced prices. Retiring mechanics and farm auction liquidations can yield excellent deals on barely-used tools. Inspect carefully for wear and damage before purchasing, as warranties rarely transfer to secondary owners.

Complementary Tools for Complete Agricultural Coverage

A jumbo ratcheting wrench set handles large fasteners excellently. However, complete agricultural maintenance requires additional tools working alongside your wrenches.

The IRONCUBE friction wrench set excels on rounded or damaged bolt heads where standard wrenches slip. The adjustable friction mechanism grips irregular surfaces that would defeat conventional box-end tools.

Combination wrenches offer open-end and box-end configurations on a single tool. For fasteners with adequate access space, these provide faster positioning than pure ratcheting designs.

Double open-end wrenches work on hydraulic fittings where box-end or ratcheting designs cannot access. These thin-profile tools slide over tubing and seat on hex flats that other wrenches cannot reach.

A comprehensive home tool set covers smaller fasteners and general maintenance tasks. While not sufficient for major equipment repairs, these sets handle countless quick adjustments and minor fixes.

Conclusion

A quality Jumbo Ratcheting Wrench Set is an essential investment for anyone working with agricultural equipment. The right set will save you time, reduce frustration, and help keep your equipment running smoothly during critical farming operations.

Whether you opt for the professional-grade IronCube Heavy-Duty set, the versatile Industrial-Grade Flex Head option, or a more budget-friendly alternative, focus on quality construction, appropriate sizing, and features that match your specific needs. With proper care and maintenance, your wrench set will provide years of reliable service, making it one of the most valuable tools in your agricultural arsenal.

FAQs

What size range should I look for in a Jumbo Ratcheting Wrench Set for farm equipment?

For most agricultural applications, a Jumbo Ratcheting Wrench Set that covers sizes from 1 inch to 2 inches will handle the majority of maintenance tasks on tractors, combines, and other farm machinery. However, if you work with specialized equipment or older models, you may need larger sizes or specific wrench profiles. It’s always best to check the fastener sizes on your specific equipment before making a purchase.

How do I maintain the ratcheting mechanism on my Jumbo Ratcheting Wrench Set?

To maintain the ratcheting mechanism on your Jumbo Ratcheting Wrench Set, clean it regularly to remove dirt and debris, then apply a small amount of penetrating oil to the moving parts. Work the mechanism back and forth to distribute the oil evenly. If you notice any skipping or rough operation, a more thorough cleaning and lubrication may be necessary. Avoid using heavy grease, as it can attract dirt and interfere with the mechanism’s operation.

Can I use a Jumbo Ratcheting Wrench Set for applications other than agricultural equipment?

Absolutely! While a Jumbo Ratcheting Wrench Set is ideal for agricultural applications, these versatile tools are also valuable for construction, heavy equipment maintenance, industrial settings, and even large automotive repairs. Their ability to handle oversized fasteners makes them useful in any setting where standard wrenches simply won’t do the job.

What’s the advantage of a flex-head design in a Jumbo Ratcheting Wrench Set?

A flex-head design in a Jumbo Ratcheting Wrench Set provides significant advantages when working in tight spaces or at awkward angles. The ability to pivot the head up to 180 degrees allows you to approach fasteners from positions that would be impossible with fixed-head wrenches. This flexibility is particularly valuable in agricultural equipment, where components are often densely packed and difficult to access.

How do I know if I need to replace my Jumbo Ratcheting Wrench Set?

Signs that it’s time to replace your Jumbo Ratcheting Wrench Set include slipping or skipping in the ratcheting mechanism, excessive play in the joint, visible corrosion that cannot be removed, or any cracks or damage to the metal. If your wrenches no longer grip fasteners securely or the ratcheting action fails to engage properly, it’s time for a replacement to avoid potential damage to your equipment or injury to yourself.