Torque represents rotational force measured in foot-pounds or Newton-meters. Too little torque leaves fasteners loose, causing failures and safety hazards. Excessive torque strips threads, cracks components, or snaps bolts entirely. Professional shops master this balance through proper technique, calibrated tools, and complete wrench coverage.

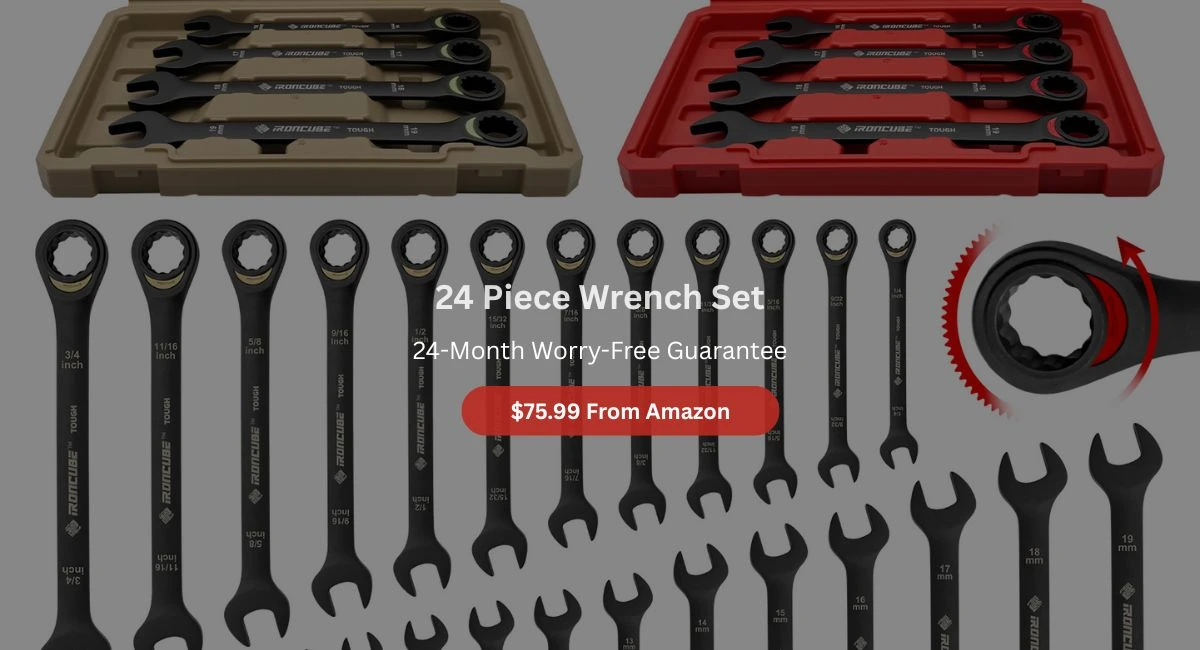

A comprehensive 24 piece wrench set provides the foundation for torque mastery. Complete size coverage eliminates improvisation with wrong-sized tools that slip and damage fasteners. Quality construction delivers consistent feel and feedback during tightening. Ratcheting mechanisms enable precise control in confined spaces where full swings prove impossible.

This guide explores torque fundamentals, explains how proper wrench selection affects torque control, and demonstrates why a complete 24-piece collection becomes indispensable for professional operations.

What is a 24-Piece Wrench Set?

A 24-Piece Wrench Set is a collection of wrenches that includes both metric and SAE (Society of Automotive Engineers) sizes. This ensures compatibility with a wide range of fasteners, making it suitable for automotive, machinery, and household repairs. The set typically includes 12 metric wrenches (8mm–19mm) and 12 SAE wrenches (1/4″–3/4″), providing full-range coverage for various applications.

The IRONCUBE 24-Piece Ratcheting Wrench Set is a prime example of this tool’s versatility. Crafted from premium Chrome Vanadium Steel, it offers durability, precision, and ease of use, making it a reliable choice for professionals and DIYers alike.

Metric Wrench Sizes (12 pcs)

8mm, 9mm, 10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm

SAE Wrench Sizes (12 pcs)

1/4″, 5/16″, 11/32″, 3/8″, 7/16″, 1/2″, 9/16″, 19/32″, 5/8″, 11/16″, 3/4″

This range covers:

Modern domestic vehicles

Imported vehicles

Industrial machines built to metric standards

Older American machinery

HVAC systems

Plumbing assemblies

Construction and fabrication equipment

Household and commercial repairs

Shops that handle mixed tooling standards benefit massively from having both SAE & metric sizes on hand at all times.

For technicians exploring wrench selection for heavy industrial use, IRONCUBE offers guidance here:

Selecting a 24-Piece Wrench Set for Heavy Industrial Use

Why Your Shop Needs a 24-Piece Wrench Set

Comprehensive Size Range

One of the standout features of a 24-Piece Wrench Set is its extensive size range. With both metric and SAE sizes included, you’ll have the right tool for virtually any fastener. This eliminates the need to purchase multiple sets or struggle with ill-fitting wrenches.

For example, the IRONCUBE 24-Piece Ratcheting Wrench Set covers sizes from 8mm to 19mm and 1/4″ to 3/4″, making it ideal for automotive, mechanical, and household repairs.

Precision and Efficiency

The 72-tooth ratcheting mechanism in the IRONCUBE 24-Piece Ratcheting Wrench Set requires only a 5° swing arc, allowing for smooth and precise operation even in tight spaces. This feature speeds up repairs and reduces fatigue, making it a favorite among professionals.

Durability and Strength

Forged from premium Chrome Vanadium Steel, the IRONCUBE 24-Piece Ratcheting Wrench Set is built to last. The anti-rust coating ensures maximum strength and corrosion resistance, making it suitable for harsh environments.

Portable and Organized Storage

Keeping your tools organized is crucial for efficiency. The IRONCUBE 24-Piece Ratcheting Wrench Set comes with a dual embedded storage case that features clear size labeling and a sturdy embedded-slot structure. This keeps your tools neatly arranged and easy to carry, whether you’re working in the shop or on the go.

Features of the IRONCUBE 24-Piece Ratcheting Wrench Set

Here’s a closer look at what makes this set stand out:

| Feature | Description |

|---|---|

| Material | Premium Chrome Vanadium Steel with anti-rust coating |

| Size Range | 8mm–19mm (Metric) and 1/4″–3/4″ (SAE) |

| Ratcheting Mechanism | 72-tooth design for smooth operation in tight spaces |

| Storage Case | Dual embedded-slot cases with clear size labeling |

| Finish | Matte finish for added durability and corrosion resistance |

| Weight | 7.72 pounds, making it lightweight yet sturdy |

Torque Fundamentals in Professional Shops

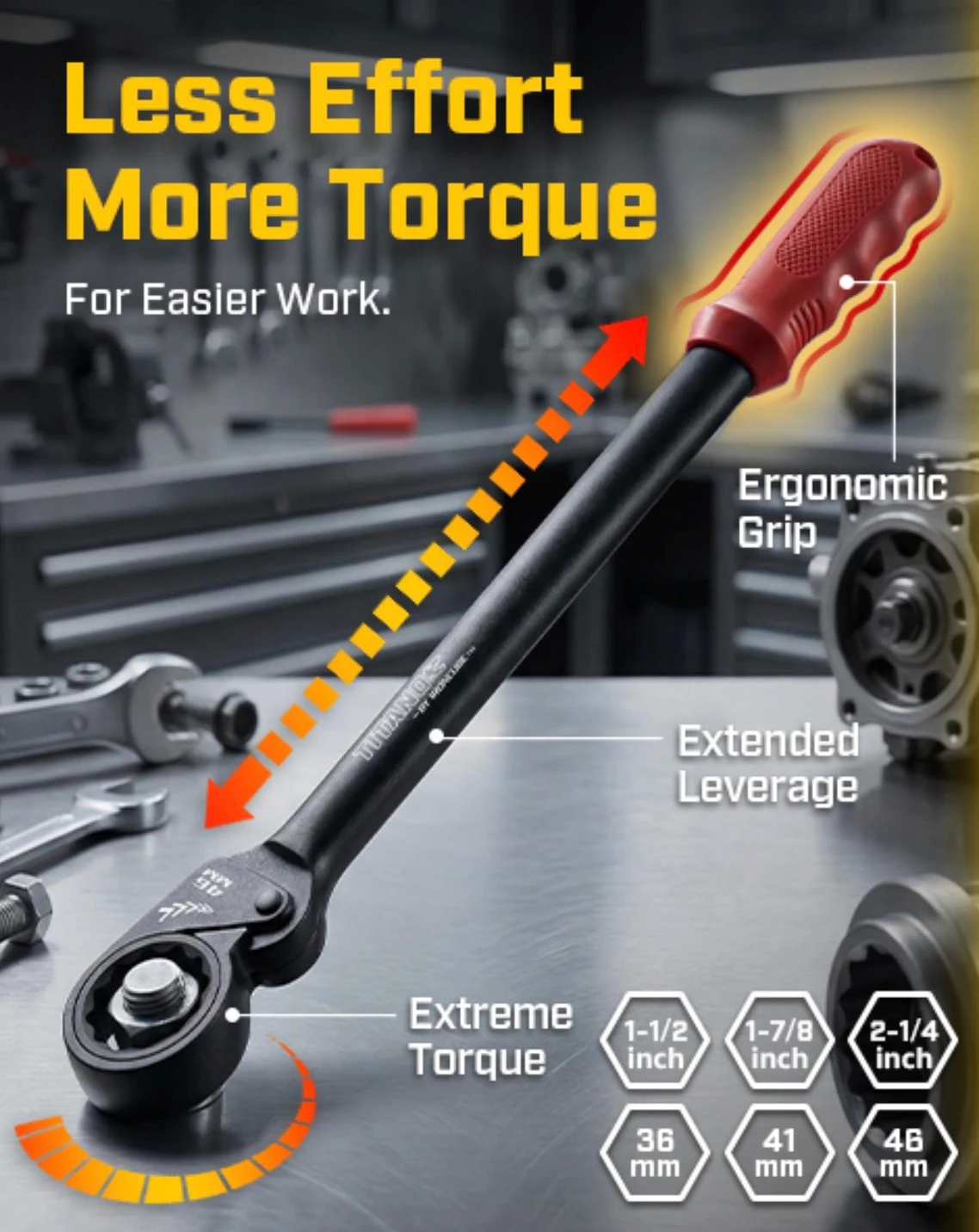

Torque calculation follows basic physics: force multiplied by distance. A wrench applying 50 pounds of force at 12 inches from the fastener generates 50 foot-pounds of torque. The same force at 18 inches produces 75 foot-pounds.

Torque specifications exist for virtually every mechanical fastener in automotive, machinery, and construction applications. Engine manufacturers specify exact torque values for cylinder head bolts, main bearing caps, and connecting rod bolts.

Automotive suspension components require precise torque. Control arm bolts, ball joint nuts, and tie rod ends all have specific requirements. Under-torquing allows movement causing premature wear. Over-torquing damages components or strips threads in aluminum suspension parts.

Wheel lug nuts represent the most commonly specified fastener facing vehicle owners and shops. Most passenger vehicles require 80-100 foot-pounds. Light trucks demand 120-140 foot-pounds. Impact wrenches easily exceed these values, leading to warped brake rotors, stripped studs, and dangerous wheel detachment risks.

Material properties influence torque specifications significantly. Aluminum components require lower torque than steel or iron. The softer material strips more easily and lacks the compressive strength of ferrous metals. Many modern engines mix aluminum blocks with steel or iron heads, demanding attention to different torque specifications throughout assembly.

Lubrication dramatically changes torque requirements. Dry threads generate more friction than oiled threads. The same 100 foot-pounds of applied torque produces different clamping forces depending on lubrication state.

Thread condition affects how torque translates into clamping force. Damaged or corroded threads increase friction unpredictably. A torque wrench might indicate proper value while the fastener remains insufficiently tight due to friction consuming applied force. Inspect threads before assembly, cleaning or replacing damaged fasteners.

The Power of Chrome Vanadium Steel in High-Stress Repairs

Professional mechanics often judge tools by their steel—and for good reason. A wrench must survive years of torque, strain, accidental drops, hard impacts, and environmental exposure.

Chrome Vanadium Steel (Cr-V) is the gold standard for mechanic-grade tools because it delivers:

• High tensile strength — handles high torque without bending

• Corrosion resistance — essential for humid shops or outdoor worksites

• Long-term durability — survives heavy use without wearing down

• Anti-rust coating — protects steel even in oil, grime, or salt exposure

Every wrench in this IRONCUBE set is forged—not cast—to maintain structural integrity and consistent performance.

Shops working on industrial-grade equipment benefit from knowing their tools won’t crack, warp, or round off the fasteners they’re meant to protect.

Why 12-Point Box Ends Matter for Bolt Protection

The IRONCUBE set uses 12-point box ends with off-corner loading. This design spreads pressure along the flat sides of the fastener instead of the corners.

That reduces:

Bolt rounding

Slipping

Premature wear

Strain on your wrist

The box end grips firmly even when fasteners are partially worn, rusted, or installed in awkward angles.

For mechanics dealing with older vehicles or machinery, this feature isn’t just handy—it prevents headaches and repeated work.

Torque Specifications Across Common Applications

Understanding typical torque values helps shops stock appropriate tools and develop technician expertise. Different applications demand varying torque ranges requiring specific wrench sizes and lengths.

Automotive Torque Requirements

| Component | Typical Torque Range | Wrench Size Needed | Application Notes |

|---|---|---|---|

| Wheel Lug Nuts (Passenger) | 80-100 ft-lbs | 17mm, 19mm, 21mm | Always use torque wrench for final tightening |

| Wheel Lug Nuts (Truck) | 120-140 ft-lbs | 21mm, 22mm | Higher torque prevents wheel separation |

| Spark Plugs | 15-25 ft-lbs | 14mm, 16mm | Over-torquing damages threads |

| Oil Pan Drain Plug | 20-30 ft-lbs | 14mm, 17mm | Aluminum pans require lower torque |

| Caliper Bracket Bolts | 70-90 ft-lbs | 14mm, 15mm, 17mm | Suspension component, safety-related |

| Caliper Slide Pins | 25-35 ft-lbs | 12mm, 13mm | Must allow caliper movement |

| Shock Absorber Mount | 50-70 ft-lbs | 15mm, 17mm, 19mm | Upper and lower mounting points |

| Control Arm Bolts | 70-100 ft-lbs | 16mm, 17mm, 18mm | Must be torqued with suspension loaded |

| Tie Rod End Nuts | 35-45 ft-lbs | 17mm, 19mm | Steering component, safety related |

| Ball Joint Nuts | 70-90 ft-lbs | 17mm, 18mm, 19mm | Often requires castle nut and cotter pin |

| Engine Mount Bolts | 40-60 ft-lbs | 14mm, 15mm, 17mm | Supports engine weight |

| Transmission Pan Bolts | 10-15 ft-lbs | 10mm, 13mm | Aluminum pan, easily stripped |

Machinery and Equipment

| Component | Typical Torque Range | Wrench Size Needed | Application Notes |

|---|---|---|---|

| Pump Housing Bolts | 30-50 ft-lbs | 12mm, 13mm, 1/2″ | Even tightening pattern required |

| Motor Terminal Connections | 15-25 ft-lbs | 10mm, 12mm, 3/8″ | Electrical connection quality affects |

| Gearbox Inspection Covers | 25-40 ft-lbs | 13mm, 14mm, 1/2″ | Gasket compression important |

| Coupling Guard Bolts | 20-35 ft-lbs | 10mm, 12mm, 7/16″ | Safety covers, regular inspection |

| Conveyor Roller Bearings | 45-65 ft-lbs | 15mm, 17mm, 5/8″ | Prevents bearing movement |

| Hydraulic Fitting Connections | 25-40 ft-lbs | Various | Depends on fitting size and type |

General Fastener Guidelines

Understanding torque requirements by fastener grade and size helps when specifications aren’t available.

Metric Grade 8.8 (Most Common)

| Bolt Size | Dry Torque | Lubricated Torque | Typical Applications |

|---|---|---|---|

| M6 | 7 ft-lbs | 5 ft-lbs | Small brackets, electrical |

| M8 | 15 ft-lbs | 11 ft-lbs | Light brackets, covers |

| M10 | 30 ft-lbs | 22 ft-lbs | Common automotive fasteners |

| M12 | 52 ft-lbs | 38 ft-lbs | Suspension, drivetrain |

| M14 | 80 ft-lbs | 59 ft-lbs | Heavy brackets, structural |

| M16 | 120 ft-lbs | 88 ft-lbs | Large structural components |

Summary

A 24-Piece Wrench Set is an essential addition to any workshop, offering versatility, precision, and durability. The IRONCUBE 24-Piece Ratcheting Wrench Set stands out with its comprehensive size range, premium materials, and convenient storage case. Whether you’re a professional or a DIY enthusiast, this set is designed to meet your needs and elevate your work.

A high-quality set, like the IRONCUBE 24-Piece Ratcheting Wrench Set, ensures Precision and Speed with its advanced 72-TOOTH PRECISION PERFORMANCE, requiring only a small 5° swing arc for efficient operation in limited space. Coupled with PROFESSIONAL GRADE DURABILITY forged from Chrome Vanadium Steel, this set guarantees longevity and fastener protection. The organized, stackable case design further adds to the operational efficiency, making the 24 Piece Wrench Set the definitive choice for professionals seeking flawless torque application and minimal downtime.

For more information or to purchase the IRONCUBE 24-Piece Ratcheting Wrench Set, visit IRONCUBE WORKS or check out our Amazon Store.

FAQs

Q1: What is the main difference between an SAE and a Metric wrench?

A1: The unit of measurement determines the sizing of wrenches. SAE (Standard/Imperial) wrenches fit fractions of an inch, such as 1/2″ or 3/4″, while Metric wrenches accommodate millimeters, like 10mm or 19mm. People highly value a 24-Piece Wrench Set because it incorporates a complete range of both SAE and Metric sizes, enabling it to handle the majority of fasteners you encounter.

Q2: Why is Chrome Vanadium Steel a preferred material for wrenches?

A2: Chrome Vanadium Steel is favored because it is an alloy specifically formulated for superior Strength and Durability. It offers high tensile strength and resistance to fatigue, ensuring the wrench doesn’t bend, snap, or wear out quickly, even under high-torque conditions.

Q3: What does the “72-tooth” count mean for a ratcheting wrench?

A3: The 72-tooth count refers to the number of engagement points in the ratcheting mechanism. A higher tooth count means a smaller degree of swing is required to turn the fastener.

Q4: Should I get a combination wrench set or just a socket set?

A4: Both are necessary. A combination wrench set (like the 24 Piece Wrench Set) is quicker for initial tightening and is essential for fasteners that are not recessed or have obstructions, as well as holding a nut while turning a bolt. A socket set is better for high-torque applications and deeply recessed fasteners. Professional shops use both.