- +86-574-87423651/87423652

- eric@ironcubeworks.com

Unlock the mysteries surrounding slotted screwdriver prices with this definitive guide. From understanding the role of brands and quality to exploring regional price variations and online vs offline costs, this article provides you with a roadmap to make informed decisions. Know what impacts the slotted screwdriver price and how you can get the best deal for your money.

IRONCUBE has a strong reputation for producing high-quality hand tools that are recognized in both the European and American markets. As a manufacturer with its own factory and R&D capability, IRONCUBE is able to offer customers a wide range of products that are constantly improving.

IRONCUBE also works with other high-end manufacturers, giving customers access to a diverse range of products. The company’s special quality inspectors and equipment ensure strict sampling inspection standards, providing customers with reliable and consistent product quality.

Additionally, IRONCUBE offers one-stop services such as brand packaging design and customization, as well as a total solution service that can be tailored to each customer’s preferences. IRONCUBE’s expertise and commitment to quality make it a trustworthy partner for customers seeking a reliable and long-term supplier of hand tools.

Overall, purchasing from IRONCUBE provides customers with access to high-quality, innovative, and customizable hand tools, as well as expert service and support.

The question of what influences the Phillips head screw price is crucial for both DIY enthusiasts and professionals. Here we uncover the various elements that determine the cost.

Material costs can significantly impact the price. Stainless steel screws are generally more expensive than zinc-plated ones.

Advanced manufacturing processes can add to the overall price. High-quality methods ensure durability but may add to the costs.

Screws produced in countries with higher labor costs can be pricier. Make sure to consider this when budgeting.

High demand can drive up prices, especially if supply is limited. Seasonal fluctuations may also play a role.

Quality control measures such as sampling inspection standards can add to the price. Products like those from IRONCUBE WORKS assure top-notch quality, but this could affect the screw's price point.

Retailers add a markup for profit. Prices can vary from store to store.

Purchasing in bulk can sometimes lead to discounts, making each screw more affordable.

Current market trends can significantly affect the pricing, whether it's due to advancements in technology or shifts in consumer preference.

The method of distribution can also impact the final price you pay. Online platforms may offer better deals compared to traditional stores.

In summary, various factors such as material, production quality, and market trends can influence the Phillips head screw price. Stay informed to make the best purchasing decisions.

Many wonder how the price of Phillips head screws stacks up against flat head screws. Here, we tackle this comparative analysis.

Both types of screws come in similar materials—stainless steel, zinc-plated, etc. Material doesn't typically differentiate the two in terms of cost.

Flat head screws require a countersinking process, which can make them slightly more expensive in some cases.

Phillips head screws are often considered more versatile. This could result in a slightly higher demand and, thus, a modestly higher price.

Phillips screws require a Phillips screwdriver, which is generally more versatile than a flat head screwdriver. This flexibility might justify a marginal price increase for Phillips screws.

Flat head screws are often used in projects requiring a flush surface. However, Phillips head screws are more commonly used in various applications, perhaps justifying a somewhat higher price.

Both types of screws usually offer bulk purchase discounts. However, because Phillips screws are more commonly used, you may find more bulk purchasing options.

Prices vary by brand. However, well-known brands might charge slightly more for Phillips screws due to their widespread use.

User preference might tilt the scale slightly towards Phillips head screws. Ease of use could contribute to higher demand and a slightly higher price.

While aesthetics may be subjective, the choice between Phillips and flat head can affect the cost if a particular style is in vogue.

Phillips head screws and flat head screws are closely matched in price. The small differences can be attributed to factors like versatility and user preference.

This should offer a comprehensive understanding of how the Phillips head screw price fares against its flat head counterpart.

The perception that you get what you pay for often rings true. But when it comes to Phillips head screws, is shelling out more money synonymous with better durability? Let's delve into this.

High-end materials like stainless steel or alloy steel usually offer better durability. These screws may be pricier but last longer.

Advanced manufacturing technologies such as cold forging contribute to the screw's strength. Hence, such screws usually have a higher price tag.

Additional coatings like anti-corrosion finishes can extend a screw's lifespan. These finishes may add to the overall cost.

Products that undergo rigorous quality control like that provided by IRONCUBE WORKS usually offer better durability and are often more expensive.

Renowned brands often produce more durable products. Their reputation can influence the higher price.

Check user reviews for insights on durability. Sometimes more expensive screws don’t necessarily offer enhanced longevity.

Certified screws that meet industry standards often assure better quality and therefore, higher durability.

Screws that come with a warranty often assure some level of quality. A longer warranty may justify a higher price.

Seasonal promotions can sometimes allow you to buy high-quality, durable screws at a discounted rate, challenging the idea that only more expensive screws are more durable.

While a higher Phillips head screw price can often indicate better quality and durability, it's not a hard and fast rule. Factors like brand, materials, and quality control are crucial in assessing durability.

The Phillips head screw price varies widely based on several factors. Here we break down the typical price ranges you can expect.

Phillips screws sizes have a substantial impact on the price. Smaller screws are generally cheaper, while larger screws cost more.

Well-known brands may charge a premium, often upwards of $0.50 per screw.

Bulk purchasing usually offers a reduced per-screw price.

Any special coatings or unique design features can increase the cost.

Prices may vary based on location due to shipping costs and local market conditions.

Different vendors offer different pricing models. Always shop around for the best deal.

Online stores may offer competitive prices but remember to account for shipping charges.

Sales and discounts can significantly lower the average price range, offering opportunities for cost-saving.

In summary, while the Phillips head screw price can vary considerably based on various factors, knowing what influences these fluctuations can guide you to make the most cost-effective choices.

When it comes to Phillips screws, understanding the sizing metrics is crucial. Let's examine how these essential fasteners are measured.

The length of the screw is often the first measurement considered. Usually, it's defined from the tip of the thread to the surface of the material into which it's driven.

Diameter refers to the width of the screw's thread. This measurement is essential for ensuring that the screw fits snugly into the material.

The size of the screw head determines the type of Phillips screwdriver needed for the job. A mismatch can result in stripping the screw head.

Higher thread count means finer threads, which offer better holding power but may be more fragile in certain applications.

Understanding the thickness of the material you're fastening into is crucial. The screw should be long enough to penetrate adequately but not too long that it punctures through the other side.

Gauge refers to the diameter of the unthreaded part of the screw. It's another critical factor that influences the screw's holding power.

Pitch measures the distance between each thread. A fine pitch usually offers better grip but might be prone to stripping.

Screws are often graded for strength. Higher grades usually signify stronger screws, thus affecting the Phillips head screw price.

The application, whether it's for wood, metal, or concrete, affects the type of Phillips screw you'll need, influencing its measurements.

Comprehensive sets like the 37pcs Ratchet Screwdriver and Socket Bit Set by IRONCUBE WORKS include screws of various sizes, providing a one-stop solution for multiple applications.

Understanding the various metrics involved in measuring Phillips screws can guide you to choose the right screws for your project, thereby optimizing both performance and cost.

Phillips head screws often overshadow their flat head counterparts in popularity. Let's explore the factors behind this trend.

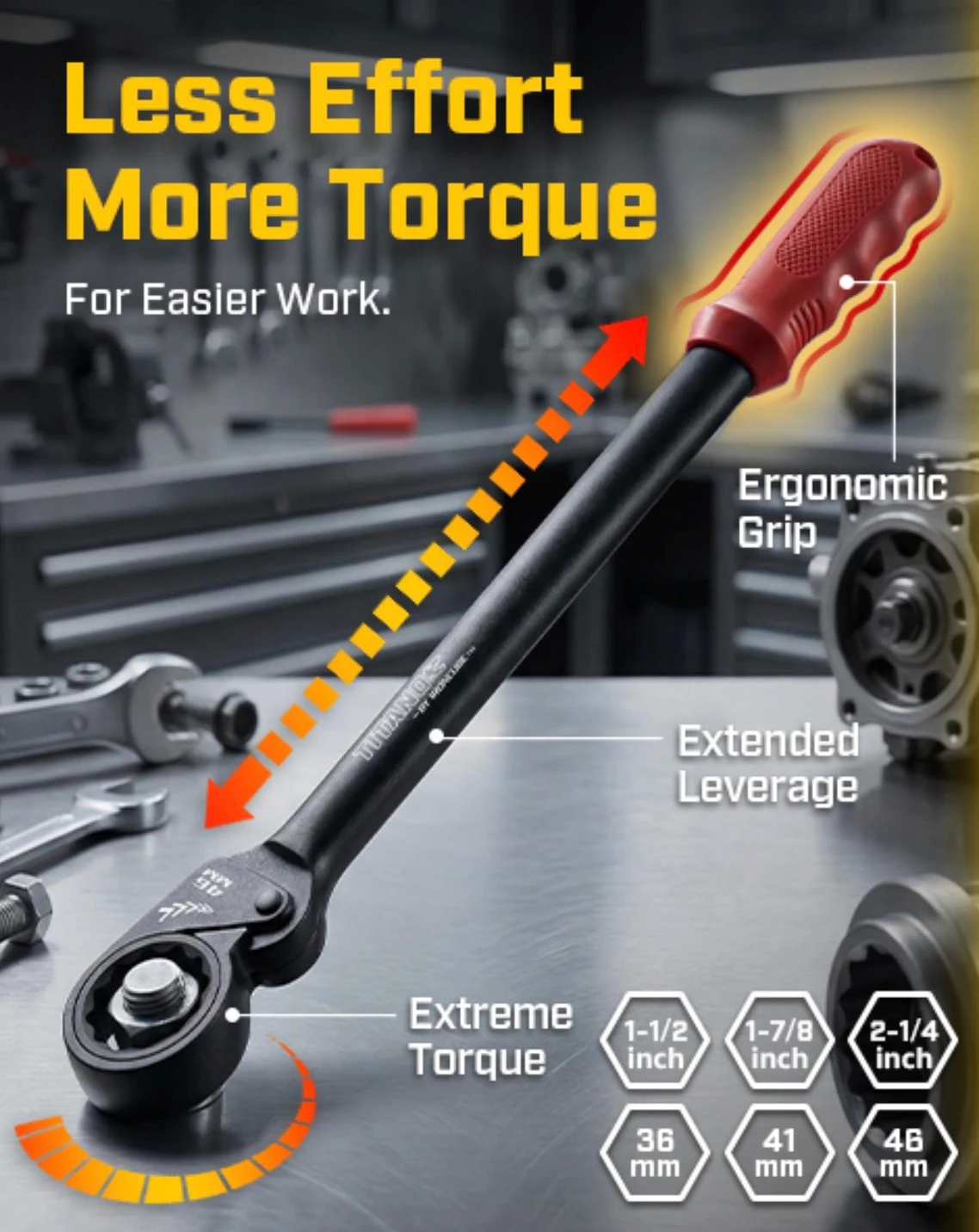

Phillips screws allow for better torque, making them easier to drive into materials.

The design of the Phillips head minimizes the chances of the screwdriver slipping out or "camming out," providing a more secure grip during installation.

Phillips screws are versatile and can be used in a variety of applications, from household repairs to industrial settings.

The cross-shaped indentation in Phillips screws ensures better alignment with the screwdriver, reducing the chances of mishandling.

The design of Phillips screws allows for quicker installation, saving time especially in large projects.

The Phillips design has led to the creation of advanced variants like Pozidriv and SupaDriv, offering even more benefits.

The risk of slippage is lower with Phillips screws, reducing the likelihood of accidents.

Some people find the look of a countersunk Phillips screw more appealing compared to a flat head screw.

Many industries prefer Phillips screws due to their enhanced features, further driving their popularity.

Phillips screws have been around for a long time, creating a level of familiarity and trust among users.

The benefits of Phillips head screws, such as better torque and reduced cam-out, often make them the go-to choice over flat head screws in various applications.

Material can significantly affect the Phillips head screw price. Let's delve into how different materials impact cost and performance.

Steel screws are often the most affordable option. However, they may lack corrosion resistance.

These offer corrosion resistance, making them suitable for outdoor applications, albeit at a slightly higher price point.

Brass screws are relatively expensive due to their unique properties like electrical conductivity.

Titanium screws are lightweight and strong but can be quite costly, reserved for special applications.

Aluminum screws are light and moderately priced but are not as durable as steel or titanium.

Screws made from alloys offer specific properties tailored for particular uses, affecting their price.

The type of coating, such as zinc or nickel, can also impact the Phillips head screw price. Coatings add extra durability and resistance.

Purchasing screws in bulk often results in a lower unit cost. Bulk packs like the 56-pcs Ratcheting Screwdriver Bits and Sockets Set offer value for money.

Any form of customization, such as special threads or heads, will inevitably increase the price.

Higher grade screws are often more expensive due to stringent manufacturing processes ensuring durability.

Different materials offer varying levels of strength, durability, and corrosion resistance, each with its own impact on price. Be sure to consider the material's properties against the demands of your specific application.

Choosing the right Phillips screw can make or break your project. Let's review some tips to make the right selection.

Ensure the screw material matches the material you're drilling into for optimal holding power.

Check that the screw's length and diameter are adequate for your specific application.

Consider the thread type—coarse or fine—based on the material and the required holding power.

Choose a head type that suits your project's aesthetics and functional needs.

Always go for screws that meet or exceed industry standards for quality, as this can be a decisive factor in the success of your project.

While the cheapest option may be tempting, remember that Phillips head screw price often reflects quality.

Select screws with the right corrosion resistance if they will be used outdoors.

Ensure your screws are compatible with your tools. If you're using a Phillips screwdriver, make sure it matches the screw head.

Some projects may need screws with special properties, such as electrical conductivity or tamper resistance.

When in doubt, consult with experts or refer to helpful guides like How to Use Screwdriver Bits for more information.

Being mindful of these factors will help you make an informed choice, ensuring that you select the right Phillips screws for your project's success.

Negotiating for better Phillips head screw prices can be a savvy business move. Here are key strategies to ensure you get the most value for your money.

Buying in larger quantities often lowers the unit price. Look for suppliers that offer bulk discounts.

Securing a long-term supply contract may make you eligible for price reductions.

Gather quotes from multiple suppliers to gain leverage in negotiations.

Some suppliers offer discounts during specific seasons or during inventory clearance.

While negotiating, ensure you're not compromising the quality of the screws. Check certifications and reviews for reliability.

Place a test order to evaluate product quality before committing to a larger purchase.

Bypass middlemen to negotiate directly with manufacturers, like IRONCUBE, to possibly lower costs.

Regularly check supplier websites for promotions or special offers, like discounted phillips screw sets.

Ask if bundling different types of screws or related products could yield a discount.

Flexible payment terms can indirectly lower your costs. Talk to your supplier about possible options.

Negotiating effectively can not only reduce your costs but can also establish a strong, long-term relationship with your supplier. Keep these tips in mind to get the best possible Phillips head screw prices.

Both Phillips head and flat head screws have distinct applications and benefits. But how do their prices compare?

Generally, Phillips head screws are more versatile but may command a slightly higher price than flat head screws.

Material costs are comparable for both types, but manufacturing complexity could influence the price.

Higher demand for Phillips head screws could result in elevated prices compared to flat head screws.

Flat head screws are often used in applications requiring a flush surface, potentially increasing their specialized demand and price.

Higher grade screws, whether Phillips or flat, will be more expensive.

Both types may come with coatings like zinc or nickel, which can affect the price.

Both screw types offer bulk pricing options. Consider packages like 47-pcs Ratchet Screwdriver and Socket Bit Set for good value.

Industries that favor one type over the other may influence the pricing of that specific type.

Both types are widely available, which keeps their prices competitive.

Ultimately, the price differences between Phillips and flat head screws are generally minimal and are influenced by factors such as material, application, and demand. Choose based on your project needs rather than cost alone.

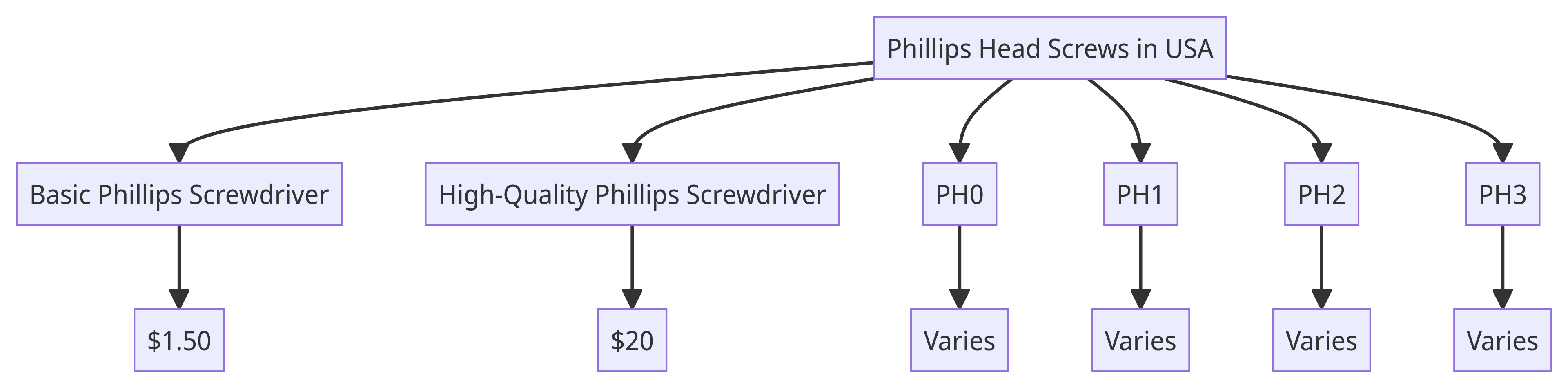

You can edit and save the diagram online using the mermaid chart editor here.

If you’re in the market for a Phillips head screw, you’ve come to the right place. This guide is your one-stop-shop for understanding the Phillips head screw price in the USA.

| Type | Price |

|---|---|

| Basic Phillips Screwdriver | $1.50 |

| High-Quality Phillips Screwdriver | $20.00 |

| PH0 | Varies |

| PH1 | Varies |

| PH2 | Varies |

| PH3 | Varies |

Note: Prices may vary depending on the retailer. It is recommended to check with the specific retailer for the most up-to-date pricing information.

The Phillips head screw price varies, but it’s more than just a number; it’s an investment in quality. Choose wisely and make quality your priority.

Elevate your toolkit with high-quality, innovative, and customizable hand tools. Experience the synergy of innovation and practicality. Quality never compromises.

Orders under 50 units: Shop our Amazon store for faster delivery and hassle-free purchasing.

Orders 50+ units: Contact our factory directly for wholesale pricing.