- +86-574-87423651/87423652

- eric@ironcubeworks.com

As a new hand tools shop owner, it is essential to understand the product you’re selling. One of the fundamental hand tools you’ll deal with is wrenches. There are several types of wrenches you should be aware of, each with their specific design, material, manufacturing process, surface treatment, and applicable working scenarios. These include combination wrenches, ratchet wrenches, adjustable wrenches, and more.

IRON CUBE has a strong reputation for producing high-quality hand tools that are recognized in both the European and American markets. As a manufacturer with its own factory and R&D capability, IRON CUBE is able to offer customers a wide range of products that are constantly improving.

IRON CUBE also works with other high-end manufacturers, giving customers access to a diverse range of products. The company’s special quality inspectors and equipment ensure strict sampling inspection standards, providing customers with reliable and consistent product quality.

Additionally, IRON CUBE offers one-stop services such as brand packaging design and customization, as well as a total solution service that can be tailored to each customer’s preferences. IRON CUBE’s expertise and commitment to quality make it a trustworthy partner for customers seeking a reliable and long-term supplier of hand tools.

Overall, purchasing from IRON CUBE provides customers with access to high-quality, innovative, and customizable hand tools, as well as expert service and support.

Each type of wrench serves a different purpose. For instance, combination wrenches have an open-end and a box-end, providing two tools in one. Ratchet wrenches feature a ratcheting mechanism allowing continuous rotation in one direction while preventing motion in the opposite direction. Understanding these designs will help you cater to various customer needs.

Wrench manufacturers typically use durable materials like chrome-vanadium steel for superior strength and longevity. The manufacturing process often involves forging, where the material is heated and hammered to take the shape of the wrench, followed by cooling and hardening. Recognizing these processes can help ensure you’re stocking quality tools.

The surface treatment of a wrench is crucial for its long-term durability. It helps enhance the tool’s ability to withstand wear and tear, corrosion, and other environmental factors. Different surface treatments provide specific benefits that contribute to the overall lifespan of the wrench.

Chrome plating is a popular surface treatment for wrenches. It offers a range of benefits, including a shiny and visually appealing finish. Additionally, chrome plating adds a protective layer that helps prevent rust and corrosion, increasing the wrench’s longevity.

In addition to chrome plating, other surface treatment options exist for wrenches. Nickel plating, for example, provides good corrosion resistance and a lustrous finish. Some manufacturers may opt for black phosphate or black oxide treatments, which give wrenches a sleek, non-reflective appearance.

When sourcing wrenches from manufacturers, it’s important to inquire about the surface treatments used. Understanding the impact of these treatments on durability, corrosion resistance, and appearance can help you make informed decisions that align with your target market’s preferences.

Product testing is a crucial step in ensuring the quality and reliability of the wrenches you sell. It helps verify that the tools meet the necessary standards and can withstand the demands of their intended use. Without proper testing, you risk selling subpar products that may fail to meet customer expectations.

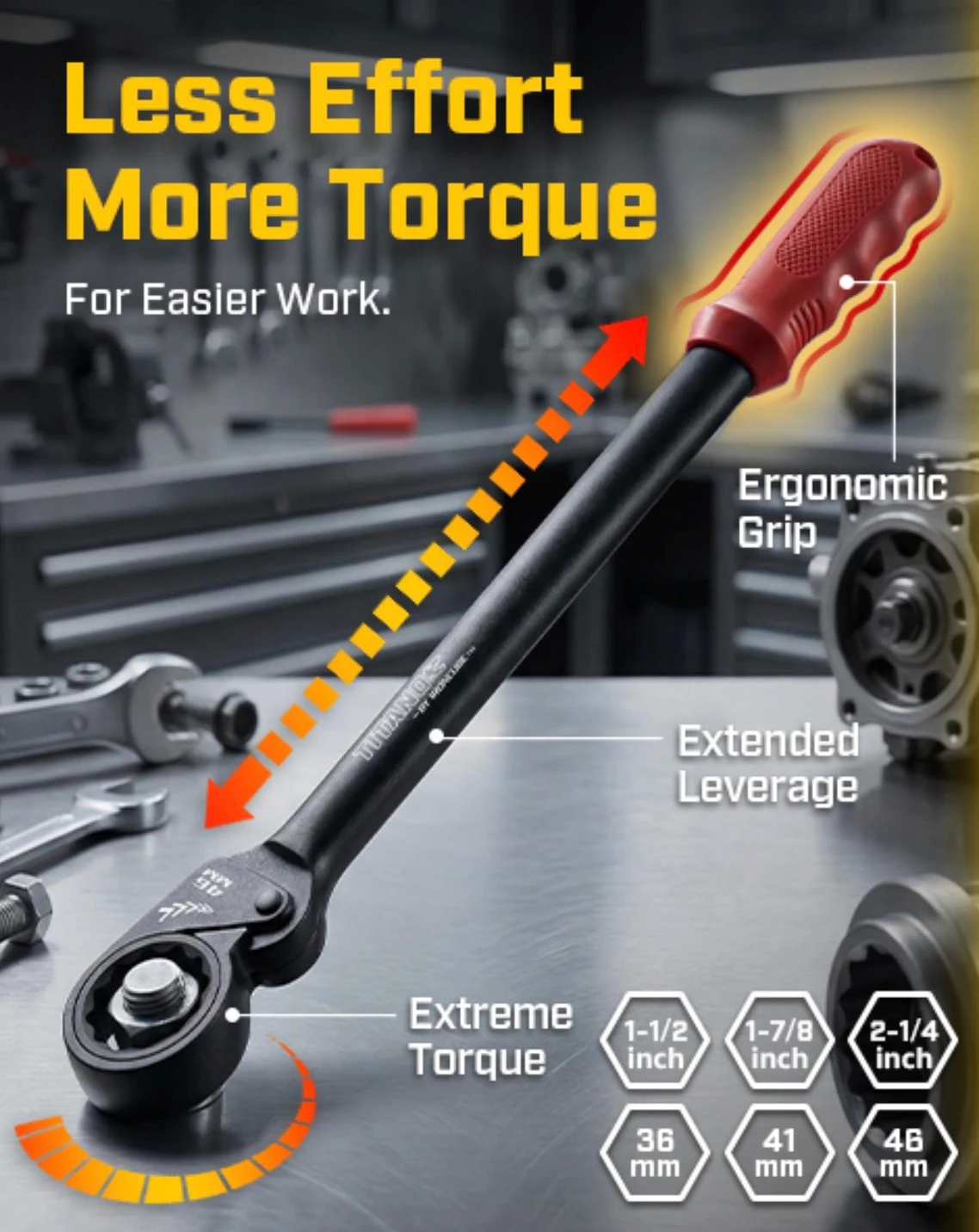

Tensile strength testing is a fundamental test for wrenches, especially when it comes to handling high torque applications. This test measures the amount of force a wrench can withstand before it breaks or deforms. It ensures that the wrench is capable of handling the required load without compromising its structural integrity.

Hardness testing is another critical evaluation for wrenches. It involves measuring the hardness of the wrench material, often using the Rockwell scale. The results provide insights into the wrench’s ability to resist wear and tear, indicating its overall durability and longevity.

Torque testing is especially important for wrenches designed to deliver specific amounts of force, such as torque wrenches. This test ensures that the wrench accurately delivers the desired torque as indicated, enabling precise tightening and loosening of fasteners. It guarantees the tool’s reliability in applications that require precise torque settings.

When sourcing wrenches from manufacturers, it’s advisable to request testing certifications or reports. These documents provide assurance regarding the quality and performance of the wrenches you are purchasing.

The IRONCUBE 10pcs new type metric ratcheting wrench set with rolling pouch and the IRONCUBE 12PCS Flexible-Head Ratcheting Wrench Set With Canvas Storage Bag have versatile applications in various industries:

Automotive and Mechanical Maintenance: These wrench sets are perfect for automotive repair shops and mechanical maintenance tasks. With their metric sizes and ratcheting capabilities, they enable efficient handling of bolts and nuts in engine repairs, suspension work, and other mechanical tasks.

Construction and Home Improvement: The flexible-head design of these wrench sets makes them ideal for construction and home improvement projects. They offer precise adjustments and tight fits in confined spaces, making them valuable tools for installing and adjusting plumbing systems, HVAC components, and other construction tasks.

The convenient storage pouches accompanying these wrench sets ensure easy organization and portability. Whether in automotive repair, construction, or home maintenance, these versatile wrench sets from IRONCUBE are designed to meet the needs of professionals and DIY enthusiasts.

In the United States, complying with established standards is essential for the wrench manufacturing process. The American Society for Testing and Materials (ASTM) plays a significant role in setting standards for various hand tools, including wrenches. For instance, ASTM F1505-10 specifically covers insulated hand tools, which is vital for wrenches used in electrical work. Adhering to these US standards ensures the safety, compatibility, and performance of the wrenches you source.

Internationally recognized standards are critical for ensuring the quality and reliability of wrenches. One prominent standard is ISO 6787:2004, which applies to adjustable open-end wrenches. It outlines dimensional and mechanical requirements that contribute to the overall quality and performance of these wrenches. Complying with international standards such as ISO 6787 ensures that the wrenches you source meet global quality and safety expectations.

When selecting a wrench manufacturer, it’s vital to verify their compliance with both US and international standards. Ensuring that the wrenches you stock meet these standards guarantees their reliability, safety, and compatibility. Compliance also fosters trust among customers, assuring them that they are purchasing high-quality tools that meet industry standards.

Finding a reliable wrench manufacturer is a crucial step in ensuring the quality and consistency of the products you stock. It involves thorough research and due diligence to select a supplier that meets your specific requirements and standards. Here are some steps to help you find a reliable wrench manufacturer:

Start your search by exploring online B2B platforms like Alibaba or Thomasnet. These platforms provide a vast database of suppliers, allowing you to browse through their product catalogs, certifications, and customer reviews. Additionally, consider attending industry-specific trade shows and exhibitions. These events offer opportunities to connect directly with manufacturers, see their products firsthand, and build relationships.

Once you’ve identified potential wrench manufacturers, it’s essential to evaluate their reliability. Look for the following aspects:

Effective communication and collaboration are key when working with a wrench manufacturer. Clear and prompt communication ensures that your requirements and expectations are understood. Discuss payment terms, lead times, order customization options, and any other specific needs you may have. Maintain an open line of communication to address any concerns or issues that may arise during the manufacturing process.

By conducting thorough research and evaluation, you can find a reliable wrench manufacturer that aligns with your business goals and ensures the delivery of high-quality products to your customers.

When considering international options for wrench suppliers, it’s essential to understand the strengths of different regions. Two prominent options are high-quality USA-made wrenches and China wrench suppliers. Here’s a closer look at their respective advantages:

USA-made wrenches are widely recognized for their exceptional quality, durability, and precision. Manufacturers in the USA adhere to stringent quality standards, resulting in reliable and long-lasting tools. These wrenches are often preferred by professionals who value performance and reliability. USA-made wrenches also offer the advantage of supporting local businesses and promoting domestic manufacturing.

China is known for its manufacturing capabilities, including the production of hand tools like wrenches. China wrench suppliers often offer competitive pricing due to lower labor and production costs. This affordability makes them an attractive option for businesses looking to offer a wide range of products at affordable prices. Additionally, China’s manufacturing infrastructure allows for high-volume production, making it suitable for businesses with large-scale operations.

IRONCUBE WORKS: IRONCUBE WORKS is a professional wrench manufacturing factory based in China. With 15 years of production and export experience, they specialize in producing various types of wrenches. Their products are known for their superior quality and excellent cost-effectiveness. IRONCUBE WORKS is committed to delivering reliable and durable wrenches to meet the needs of their customers.

By considering renowned manufacturers like Stanley, Milwaukee, Snap-on, and the reliable China wrench manufacturer IRONCUBE WORKS, you can source high-quality wrenches that meet your customers’ expectations. Conduct thorough research, evaluate product quality and specifications, and consider customer reviews to choose the right manufacturer for your business.

When deciding between high-quality USA-made wrenches and China wrench suppliers, consider your target market, pricing strategy, and customer preferences. If you cater to professionals or prioritize premium quality, investing in USA-made wrenches can differentiate your business and meet the demands of discerning customers. On the other hand, if affordability and a broader product range are critical, China wrench suppliers can provide cost-effective options and cater to a wider customer base.

Ultimately, the right fit depends on your business goals, target market, and pricing strategy. Evaluate the advantages of each region, consider your customers’ needs, and select a supplier that aligns with your overall business strategy.

Budgeting involves understanding your financial limitations and forecasting potential expenses, including product cost, shipping, taxes, and other overhead costs. Price negotiation with the supplier requires an understanding of market prices and demonstrating the value of a potential long-term partnership.

Leverage market research reports and online tools to understand the sales data and trends for wrenches in the US market. Additionally, online reviews and buyer feedback can provide insights into customer needs and common pain points.

Choosing the right shipping method for your wrenches depends on various factors. Consider the following:

When it comes to payment terms, several options are available:

Consider the financial capabilities of your business and the trustworthiness of your supplier when determining the most suitable payment terms for your wrench orders.

Importing products into the US involves complying with Customs and Border Protection (CBP) regulations. Here are a few key points to keep in mind:

Consult with a customs broker or seek professional advice to ensure compliance with the specific requirements and regulations for importing wrenches into the US.

As a new hand tools shop owner, it’s essential to understand how to pay import duties when sourcing products internationally. The US uses a tariff schedule to calculate these duties. Be sure to correctly classify your products using the Harmonized System (HS) code to determine the correct tariff.

Running a successful hand tools shop isn’t a set-and-forget endeavor. It requires continual optimization to keep up with industry trends, customer preferences, and evolving market dynamics. Regularly reassess your product offerings, pricing strategies, and supplier relationships to stay competitive.

The journey to becoming a successful hand tools shop owner is both challenging and rewarding. From understanding the intricacies of wrench types and their manufacturing standards to establishing reliable supplier relationships, each step is a learning experience. Regularly reviewing market trends, customer feedback, and supplier performance are vital for continual optimization and success. Remember, the key lies in providing high-quality products that cater to your customers’ needs while ensuring smooth business operations.

When choosing a wrench manufacturer, consider factors such as the range of products they offer, their manufacturing standards, quality control procedures, pricing, reputation in the market, and their responsiveness to your inquiries.

Request your manufacturer for product certifications that prove their adherence to international and US standards. Additionally, consider hiring a third-party inspection service to verify product quality and compliance before shipment.

High-quality USA-made wrenches are often associated with superior build quality and durability, which can be a major selling point for customers. They can also enhance your shop’s reputation and contribute to higher customer satisfaction.

Import duties are calculated based on the product’s HS code as per the US tariff schedule. It’s advised to work with a customs broker or a legal expert to ensure correct product classification and accurate calculation of import duties.

Orders under 50 units: Shop our Amazon store for faster delivery and hassle-free purchasing.

Orders 50+ units: Contact our factory directly for wholesale pricing.