- +86-574-87423651/87423652

- eric@ironcubeworks.com

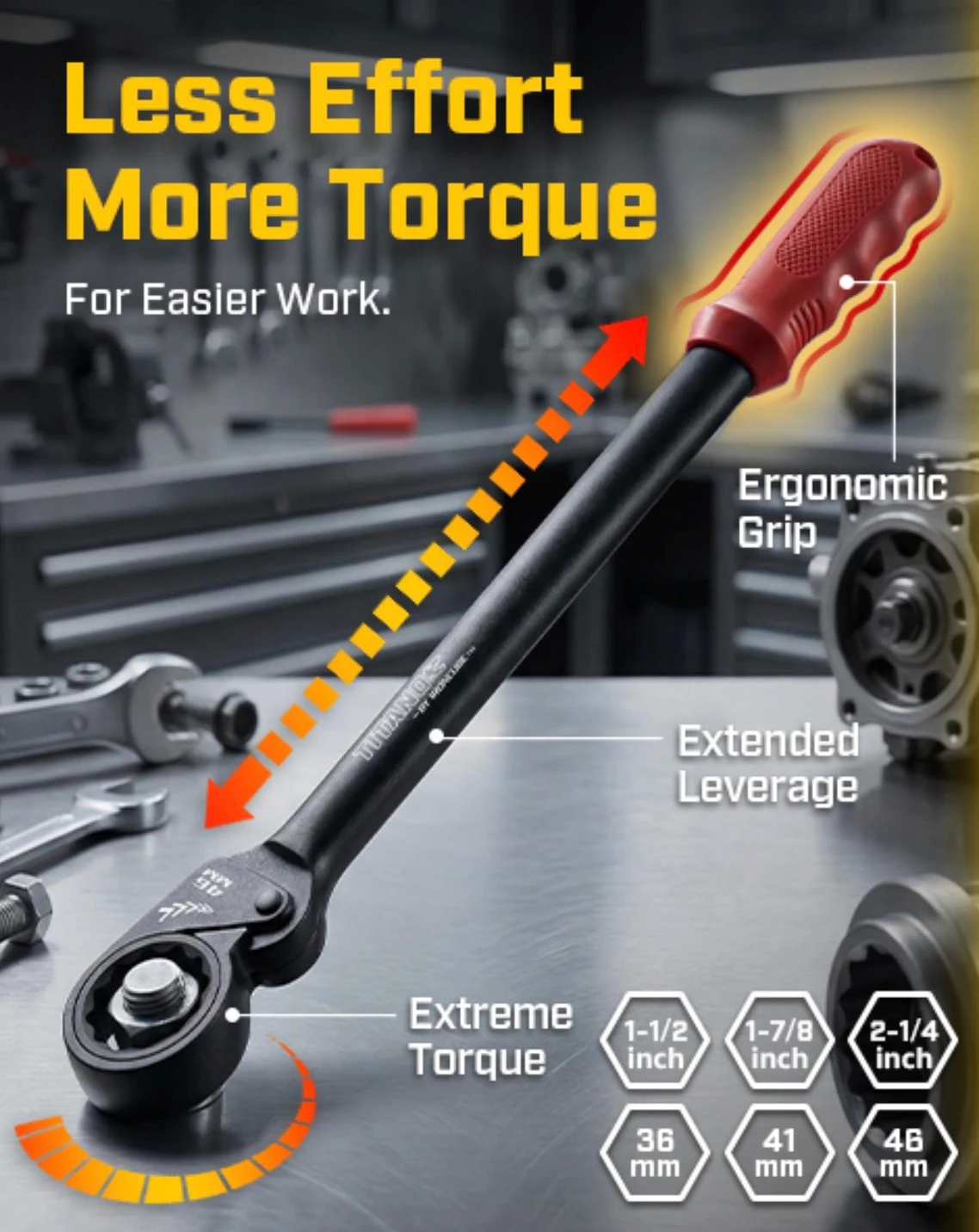

Become a wrench manufacturers in Alabama? In recent years, Alabama has become an attractive location for businesses due to its growing economy and advantageous business environment. As a wrench manufacturer looking to establish a production factory in the state, it is essential to have a detailed and implementable plan to ensure success. This comprehensive guide covers critical aspects of setting up a wrench manufacturing factory in Alabama, including location selection, production processes, workforce requirements, marketing, distribution strategies, and more.

IRON CUBE has a strong reputation for producing high-quality hand tools that are recognized in both the European and American markets. As a manufacturer with its own factory and R&D capability, IRON CUBE is able to offer customers a wide range of products that are constantly improving.

IRON CUBE also works with other high-end manufacturers, giving customers access to a diverse range of products. The company’s special quality inspectors and equipment ensure strict sampling inspection standards, providing customers with reliable and consistent product quality.

Additionally, IRON CUBE offers one-stop services such as brand packaging design and customization, as well as a total solution service that can be tailored to each customer’s preferences. IRON CUBE’s expertise and commitment to quality make it a trustworthy partner for customers seeking a reliable and long-term supplier of hand tools.

Overall, purchasing from IRON CUBE provides customers with access to high-quality, innovative, and customizable hand tools, as well as expert service and support.

Choosing the right location for your wrench manufacturing factory is crucial. Key factors to consider include accessibility to transportation, availability of skilled labor, infrastructure, and proximity to suppliers and distributors. Birmingham, Huntsville, and Mobile are popular industrial hubs in Alabama that offer these advantages, making them suitable locations for your factory. Moreover, collaborating with local Wrenches Suppliers in Alabama can provide additional support and resources for your business.

Efficient and streamlined production processes are vital to ensure the quality and cost-effectiveness of your wrenches. Invest in modern machinery, such as forging machines, CNC machines, grinding machines, heat treatment equipment, and finishing machines, to optimize productivity and precision. Implement strict quality control measures to maintain high production standards and train your workforce to handle the equipment effectively. Working with experienced Tool Manufacturers in Alabama can also provide valuable insights and expertise.

The quality of your wrenches heavily depends on the raw materials used during production. High-quality steel and alloy materials, such as chrome vanadium steel and carbon steel, are popular choices due to their strength, durability, and resistance to wear and corrosion. Collaborate with reliable suppliers to ensure a consistent supply of high-quality materials at competitive prices.

A skilled workforce is crucial for the successful operation of your wrench manufacturing factory. Begin by recruiting a small team of 10-20 workers with expertise in machine operation, quality control, and assembly. As your business expands, adjust your workforce accordingly. Invest in employee training and development to enhance their skills and maintain high production standards.

The size and layout of your factory will depend on your production capacity and equipment requirements. For a small-scale operation, a facility of 5,000 to 10,000 square feet should suffice. Ensure there is adequate space for production lines, storage, and administrative offices. A well-designed factory layout can improve productivity and workflow while minimizing bottlenecks and inefficiencies.

Creating a recognizable and trustworthy brand is essential for establishing your presence as a wrench manufacturer in Alabama. Focus on the unique selling points of your wrenches, such as durability, precision, and ergonomic design. Develop a compelling brand identity that resonates with your target audience and highlights your commitment to quality. Design a comprehensive marketing strategy that utilizes both online and offline channels, including search engine optimization (SEO), social media, trade shows, and local advertising.

A robust distribution network is critical for delivering your wrenches to customers throughout Alabama. Work with experienced Wrench Suppliers and distributors to ensure your products reach retailers, workshops, and other potential customers. Establishing strategic partnerships with Wrench Wholesalers in Alabama can also help you access new markets and share resources, further strengthening your position in the industry.

Adhere to all local and federal regulations regarding the production and distribution of wrenches. Obtain necessary permits and certifications, and maintain a safe working environment in your factory to protect your employees and your business reputation.

To estimate the required investment, consider the following factors:

Once you have a detailed budget, seek funding through various channels, such as personal savings, bank loans, government grants, or investment from business partners.

In conclusion, establishing a successful wrench manufacturing factory in Alabama requires thorough research, planning, and execution. By following this comprehensive guide and focusing on location selection, production processes, raw materials, workforce, marketing, and distribution, you can create a thriving business in the competitive hand tool industry.

As an aspiring wrench manufacturer in Alabama, it is essential to have a comprehensive plan to set up a successful production factory. This guide provides detailed answers to your specific questions, focusing on critical aspects such as location, equipment, raw materials, workforce, factory size, distribution channels, and budget.

Birmingham, Huntsville, and Mobile are ideal cities for your wrench manufacturing factory in Alabama. These cities offer excellent infrastructure, access to skilled labor, and proximity to major transportation networks, making them popular industrial hubs. Additionally, working with local wrench Manufacturers in Alabama can provide further support and resources for your business.

To ensure an efficient and streamlined production process for wrench Manufacturers in Alabama, you’ll need the following equipment:

High-quality steel and alloy materials, such as chrome vanadium steel and carbon steel, are crucial for wrench production. These materials are known for their strength, durability, and resistance to wear and corrosion, ensuring the quality and longevity of your wrenches.

Wrench Manufacturers in Alabama may start by recruiting a small team of 10-20 workers with expertise in machine operation, quality control, and assembly. As your business grows, you can adjust the size of your workforce accordingly

For a small-scale wrench manufacturing operation, a factory of 5,000 to 10,000 square feet should be sufficient. Ensure there is adequate space for production lines, storage, and administrative offices.

Establish a strong distribution network by partnering with experienced Wrench Suppliers and distributors in Alabama. They can help ensure your products reach retailers, workshops, and other potential customers. Collaborating with Wrench Wholesalers in Alabama can also provide access to new markets and share resources.

Initial costs for establishing a wrench manufacturing factory include land acquisition or rental, factory construction, equipment purchase, raw material procurement, workforce recruitment, and marketing. Ongoing expenses include utilities, maintenance, salaries, and marketing costs. Research local prices, request quotes from suppliers, and calculate wages based on industry standards to create a detailed budget. Seek funding through personal savings, bank loans, government grants, or investment from business partners.

In conclusion, establishing a wrench Manufacturers in Alabama requires thorough research, planning, and execution. By following this detailed guide and focusing on location, equipment, raw materials, workforce, marketing, and distribution, you can create a thriving business in the competitive hand tool industry.

Read More:

How to choose 15PCS SAE Combination Wrench Set With Rolling Pouch for Every DIY Enthusiast

Get A complete guide to 3PCS Metric Brake Line Wrench Set With Rolling Pouch

Try for free 10PCS Metric Ratcheting Wrench Set WithRolling Pouch

Orders under 50 units: Shop our Amazon store for faster delivery and hassle-free purchasing.

Orders 50+ units: Contact our factory directly for wholesale pricing.