- +86-574-87423651/87423652

- eric@ironcubeworks.com

Are you a wholesale distributor searching for trusted suppliers? Discover our comprehensive guide on sourcing and selling wholesale wrenches. Learn about different wrench types, effective sourcing strategies, and essential techniques for successful selling. With a focus on high-quality products and customer satisfaction, you can establish yourself as a reputable wholesale supplier in the wrench industry.

IRON CUBE has a strong reputation for producing high-quality hand tools that are recognized in both the European and American markets. As a manufacturer with its own factory and R&D capability, IRON CUBE is able to offer customers a wide range of products that are constantly improving.

IRON CUBE also works with other high-end manufacturers, giving customers access to a diverse range of products. The company’s special quality inspectors and equipment ensure strict sampling inspection standards, providing customers with reliable and consistent product quality.

Additionally, IRON CUBE offers one-stop services such as brand packaging design and customization, as well as a total solution service that can be tailored to each customer’s preferences. IRON CUBE’s expertise and commitment to quality make it a trustworthy partner for customers seeking a reliable and long-term supplier of hand tools.

Overall, purchasing from IRON CUBE provides customers with access to high-quality, innovative, and customizable hand tools, as well as expert service and support.

Combination wrenches, also known as spanners, are versatile tools with an open-end on one side and a box-end on the other. Such as IRONCUBE 15PCS Metric Combination Wrench Set With Rolling Pouch, They allow users to choose the most suitable end for different fasteners, providing flexibility and convenience. Combination wrenches are commonly used in automotive repair, construction projects, and general maintenance tasks. They are available in various sizes to accommodate different nut and bolt dimensions.

Open-end wrenches have U-shaped jaws on both ends, allowing them to fit over fasteners with ease. Their design enables quick access in tight spaces where other wrench types may not fit. Such as IRONCUBE ANSI Standard Double Open End Wrench, Open-end wrenches are often used in plumbing, electrical work, and HVAC systems. They come in various sizes and are lightweight, making them portable and versatile for different applications.

Box-end wrenches, also called closed-end wrenches, have an enclosed head with a six-sided opening that provides a more secure grip on fasteners. The closed design prevents slippage and distributes torque evenly. Such as IRONCUBE ANSI Standard Double Ring End Wrench, Box-end wrenches are ideal for heavy-duty applications that require higher torque, such as industrial machinery repairs and construction projects. They are available in both metric and imperial sizes to accommodate different bolt heads.

Wrenches are indispensable tools in the realm of automotive repair and maintenance. They are crucial for various tasks, including engine repairs, suspension work, and brake system maintenance. When it comes to general repairs, mechanics often rely on combination wrenches, while specialized wrenches like oil filter wrenches or spark plug wrenches are necessary for specific automotive tasks. With the diverse assortment of wrench sizes available, mechanics can effectively handle nuts and bolts of varying dimensions in vehicles.

In the construction industry, wrenches are indispensable for various applications. From plumbing installations to electrical connections and structural assemblies, wrenches are used extensively. Combination wrenches and open-end wrenches are frequently employed in construction projects due to their versatility and accessibility in tight spaces. Box-end wrenches provide higher torque for heavy-duty construction tasks that require more force.

In manufacturing and industrial settings, wrenches are utilized for equipment assembly, maintenance, and repairs. Combination wrenches, with their dual-end design, offer versatility and efficiency in handling different fasteners. Open-end wrenches are suitable for quick adjustments and accessibility. Box-end wrenches are essential for heavy machinery repairs and applications where higher torque is required to tighten or loosen bolts.

Wrenches are valuable tools for DIY enthusiasts and homeowners. They come in handy for various home improvement projects, furniture assembly, and basic repairs. With the right set of wrenches, DIYers can confidently tackle a wide range of projects.

Quality is a crucial factor in wholesale wrenches. Appearance and dimension control are essential quality indicators. Compliance with relevant standards is important, such as the ANSI B107 series for US standards and ISO 1711-1:2019 for international standards. Accurate torque values are vital for proper wrench functionality. Ensure that the wrenches you source meet these standards and specifications to provide customers with reliable and durable tools.

Wrenches are required to meet certain appearance and dimension criteria according to ISO 1711-1 or ANSI B107. The standard specifies that the dimensions of the wrench, such as the width across flats, the overall length, and the thickness, should fall within specified tolerances. The finish of the wrench should be smooth and free from any defects that may affect its performance or appearance. Additionally, the standard outlines requirements for the design of the wrench, including the shape and profile of the jaws and the positioning of the box and open ends.

By adhering to the appearance and dimension control requirements specified in ISO 1711-1 or ANSI B107 wrench wholesaler can ensure that their combination wrenches, open-end wrenches, and box-end wrenches meet the necessary standards for quality, compatibility, and performance.

Wrenches are designed to operate within a specific torque range, which is expressed in units such as foot-pounds (ft-lb), Newton-meters (Nm), or inch-pounds (in-lb).

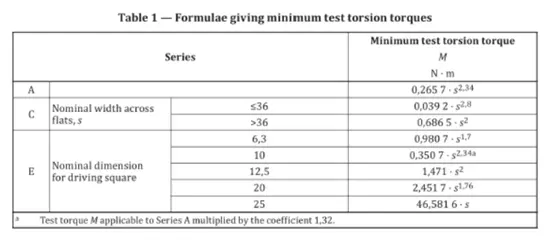

According to ISO 1171 standard, here are some requirements for wrench torque:

It is important to note that ISO 1171 is an international standard applicable to wrench manufacturing and usage worldwide. It provides basic requirements and guidance for wrench torque, but specific torque requirements may vary based on specific applications and industry needs. Therefore, it is recommended to refer to the ISO 1171 standard and the guidelines and specifications provided by wrench manufacturers to ensure a proper understanding and compliance with applicable torque requirements before using wrenches in practice.

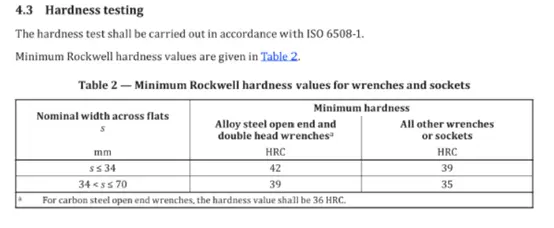

Under ISO 1711-1, which specifies the requirements for hand-operated wrenches, there are specific hardness requirements to ensure the quality and durability of the wrenches. Here is a description of the hardness requirements according to ISO 1711-1:

ISO 1711-1 outlines the hardness requirements for wrenches by specifying the hardness scale and the corresponding hardness values that the wrench material should meet. The Rockwell hardness scale is commonly used to measure the hardness of the material.

The standard typically defines a range of hardness values that the wrench material must fall within. For instance, for carbon steel wrenches, the hardness requirement may be specified as a minimum and maximum Rockwell hardness value. The range may vary depending on the specific type of wrench and its intended application.

The hardness requirement ensures that the wrench material possesses the necessary strength and resistance to deformation during use. An appropriate hardness level enables the wrench to withstand the forces and stresses encountered during fastening and loosening operations without excessive wear or deformation.

Manufacturers must adhere to the hardness requirements outlined in ISO 1711-1 to ensure that the wrenches they produce meet the required quality standards. By complying with the hardness requirements, manufacturers can provide wrenches that exhibit the desired mechanical properties and perform effectively in various working environments.

ANSI B107 and ISO 1711 are both standards that provide requirements for hand-operated wrenches. While they share similarities in terms of ensuring the quality and performance of wrenches, there are some differences in their specific requirements. Here are some key differences between B107 and ISO 1711:

It is important for manufacturers, distributors, and users of wrenches to be aware of the applicable standard and ensure compliance with the specific requirements relevant to their region or market. Consulting the respective standards (B107 or ISO 1711) and adhering to the applicable requirements will help ensure the production and use of high-quality wrenches that meet the necessary standards and specifications.

By providing your customers with high-quality wrenches, you ensure that they can rely on the tools to perform their tasks effectively and efficiently. The durability, precision, and reliable performance of quality wrenches will result in greater customer satisfaction and trust in your products.

When customers have a positive experience with the wrenches you supply, they are more likely to become repeat buyers. Their satisfaction and confidence in the quality of your products will lead to continued business relationships and repeat orders, contributing to long-term customer loyalty and increased sales.

Procuring quality wrenches establishes your wholesale business as a reliable source of superior tools. Word-of-mouth recommendations and positive reviews from satisfied customers will enhance your reputation and brand image in the market. A strong reputation will attract more customers, boosting your sales and market share.

High-quality wrenches are less likely to have manufacturing defects or performance issues. This leads to a decrease in product returns and warranty claims, saving you time and money associated with handling and replacing faulty items. It also enhances your credibility as a distributor of reliable products.

Offering top-notch wrenches gives you a competitive edge in the wholesale market. As customers increasingly seek quality tools, your ability to provide durable and precise wrenches will differentiate you from competitors offering lower-quality products. This competitive advantage can attract new customers and secure long-term partnerships with retailers and other businesses.

When considering international options for wrench suppliers, it’s essential to understand the strengths of different regions. Two prominent options are high-quality USA-made wrenches and China wrench suppliers. Here’s a closer look at their respective advantages:

Procuring high-quality wrenches for wholesale distribution brings a multitude of benefits to your business. By prioritizing quality, you can ensure customer satisfaction, foster repeat business, enhance your reputation, reduce returns, and gain a competitive edge in the market. Whether it’s wholesale industrial wrenches, wrench and spanner tools, or spanner products, sourcing top-notch wrenches will contribute to the long-term success and profitability of your wholesale distribution business.

Remember, at IRONCUBE WORKS, we offer a wide range of wholesale wrenches, including industrial wrenches, wrench and spanner tools, and spanner products, available for purchase online. Contact us today to explore our high-quality wrenches and elevate your wholesale business with reliable and durable tools.

Orders under 50 units: Shop our Amazon store for faster delivery and hassle-free purchasing.

Orders 50+ units: Contact our factory directly for wholesale pricing.