When it comes to heavy equipment maintenance and repair, having the right tools isn’t just a convenience—it’s a necessity. Among the most critical tools in any heavy equipment technician’s arsenal are 36mm to 46mm wrenches, specialized implements designed to tackle the large bolts and fasteners found in industrial machinery, agricultural equipment, and construction vehicles. These substantial wrenches provide the torque and leverage needed to secure and loosen the massive components that keep heavy machinery operating safely and efficiently. In this comprehensive guide, we’ll explore the vital role these tools play across various industries, examine their different types and applications, and provide valuable insights for selecting and maintaining the perfect wrenches for your specific needs.

Why the 36mm to 46mm Range Matters in Heavy Equipment

Most people outside of industrial maintenance and heavy construction never encounter fasteners in this size range. But for the professionals who do, these wrenches represent some of the most important tools in the shop. Here’s why this particular range is so significant.

It covers the transition zone between “large” and “jumbo.” Fasteners below 36mm can often be handled with extended standard wrench sets or large socket sets driven by a 1/2-inch ratchet. Once you cross the 36mm threshold, you’re firmly in territory that requires dedicated jumbo wrenches — tools with longer handles, thicker beams, and stronger ratcheting mechanisms designed specifically for high-torque applications.

The torque requirements jump dramatically. A 36mm bolt on a piece of heavy equipment might require 200 ft-lbs of torque. A 46mm bolt on the same machine could demand 400 ft-lbs or more. The tools that handle these fasteners need to withstand those forces repeatedly without deforming, cracking, or stripping. That’s a fundamentally different engineering challenge than building a 14mm wrench.

Failure at these sizes has serious consequences. When a 10mm bolt strips, you’re annoyed. When a 46mm structural bolt on a crane fails because someone used the wrong tool and damaged the fastener, people can get hurt. The stakes involved with 36mm to 46mm wrenches make tool quality and proper sizing critically important in ways that smaller tools simply don’t face.

The Heavy Equipment Applications: Where Each Size Gets Used

Not every wrench in this range does the same job. Each size corresponds to specific fastener standards used across different industries and equipment types. Understanding which sizes you’ll encounter in your particular field helps you invest in the right tools rather than buying every size and hoping for the best.

36mm Wrenches: The Gateway to Jumbo Territory

The 36mm size sits right at the boundary between what some standard sets cover and where jumbo territory officially begins. It’s one of the most commonly needed sizes in heavy equipment work, appearing across a wide range of applications.

Hydraulic fittings and connectors on excavators, backhoes, and wheel loaders frequently use 36mm hex fittings. These connections carry pressurized fluid at thousands of PSI, so a secure, non-damaging fit is essential. Using the wrong wrench and rounding off a hydraulic fitting creates a leak path that can sideline an expensive machine for days.

Suspension and axle components on Class 7 and Class 8 trucks often include 36mm fasteners. Steer axle king pin bolts, suspension U-bolt nuts, and certain wheel hub assemblies all fall in this size range. Fleet maintenance shops keep 36mm wrenches within arm’s reach because these fasteners come up during routine service intervals.

Structural connections in steel-frame buildings and industrial facilities use 36mm high-strength bolts for secondary structural members. Erectors and ironworkers need tools that can tighten these bolts to specification without damaging the connection.

IRONCUBE offers a dedicated 36mm torque friction wrench that covers this entry point to the jumbo range. It’s a practical starting place for anyone building out their large-wrench collection.

41mm Wrenches: The Heavy Industrial Workhorse

Step up to 41mm and you’re solidly in heavy industrial territory. Fasteners this size appear on equipment that operates under enormous loads and vibration.

Mining equipment is one of the primary domains for 41mm fasteners. Jaw crushers, cone crushers, and vibrating screens use bolts this size to secure major structural and wear components. These fasteners endure constant vibration and impact loading, which means maintenance crews need tools that deliver precise, reliable torque every time.

Marine and offshore applications use 41mm bolts on crane pedestals, winch assemblies, and structural connections on vessels and platforms. Saltwater corrosion makes these fasteners notoriously difficult to service — they seize, they rust, and they fight back. A quality wrench with a strong ratcheting mechanism is the difference between a 30-minute job and a four-hour ordeal.

Power generation equipment including turbines, generators, and large pump assemblies rely on 41mm fasteners for casing bolts and mounting hardware. These installations demand careful torque control because overtightening or undertightening can cause vibration, leaks, or catastrophic failure during operation.

The IRONCUBE 41mm jumbo ratchet spanner addresses this segment with a friction-type ratcheting mechanism that handles the torque demands without gear-tooth stripping — a common failure point for traditional ratchets at this size.

46mm Wrenches: The Top of the Range

The 46mm wrench is the largest metric size that most professional tool manufacturers stock as a standard offering. It’s reserved for the biggest, heaviest, most demanding applications in heavy industry.

Structural steel erection on major infrastructure projects — bridges, stadium roofs, high-rise buildings, communication towers — uses 46mm high-strength bolts for primary structural connections. These are the bolts that hold the skeleton of a building together. Every single one must be properly tightened, and many need to be verified with calibrated torque equipment. The wrench used to install and service them has to deliver consistent, damage-free performance.

Wind turbine assembly and maintenance involves 46mm fasteners on tower sections, nacelle mounting bolts, and foundation anchor bolts. Wind turbines operate in harsh environments — temperature swings, moisture, vibration — and every maintenance visit requires climbing a tower and working in a confined nacelle. Having 36mm to 46mm wrenches that you can trust at the top of a 300-foot tower isn’t optional.

Large-scale mining and earthmoving equipment, including haul trucks, draglines, and large hydraulic excavators, uses 46mm bolts on critical chassis, boom, and undercarriage components. The IRONCUBE 46mm friction ratcheting spanner was designed specifically for these extreme applications, with chrome vanadium steel construction and a 12-point box end that engages every 30 degrees.

For a complete comparison of the best large-wrench options, see this roundup of big ratchet wrenches for heavy equipment.

Metric vs. Imperial: Getting the Right Fit in the 36mm to 46mm Range

One of the most common — and most costly — mistakes in heavy equipment maintenance is using a wrench that’s close to the right size but not exact. In the jumbo range, the metric and imperial systems run frustratingly close together, which tempts some technicians into using a “near-enough” fit. Here’s why that approach backfires.

| Metric Size | Closest Imperial Equivalent | Actual Difference |

|---|---|---|

| 36mm | 1-7/16 inch (36.51mm) | 0.51mm gap |

| 38mm | 1-1/2 inch (38.10mm) | 0.10mm gap |

| 41mm | 1-5/8 inch (41.28mm) | 0.28mm gap |

| 46mm | 1-13/16 inch (46.04mm) | 0.04mm gap |

Those gaps might look small on paper, but on a hardened hex bolt under 300+ ft-lbs of torque, even a fraction of a millimeter of slop turns into rounding force on the corners of the fastener head. A rounded 46mm bolt on a bridge connection or a mining crusher isn’t just an inconvenience — it’s a serious problem that can require destructive removal and replacement of both the fastener and potentially the surrounding hardware.

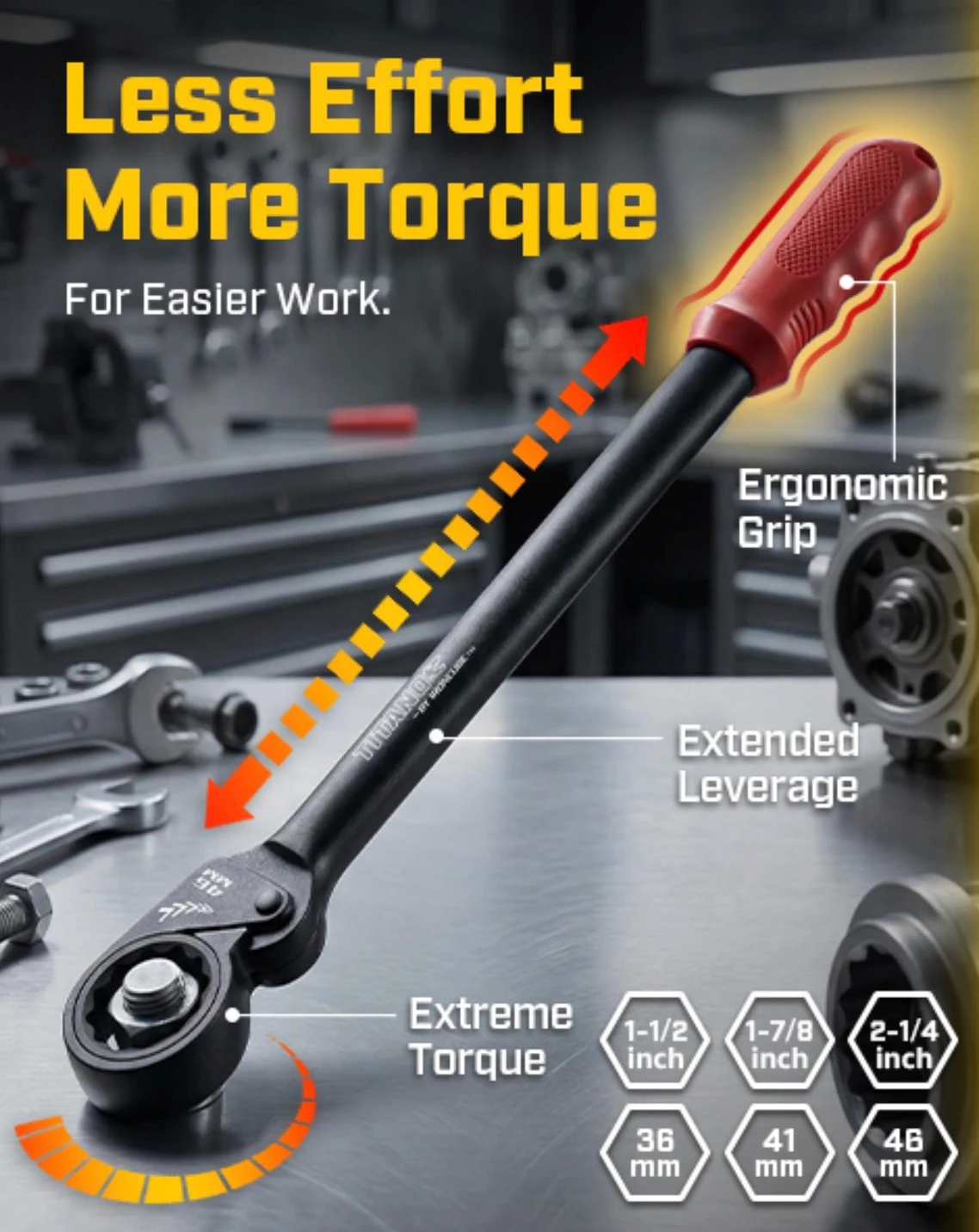

Always use the correct measurement system for the fastener. If the equipment uses metric bolts, use metric wrenches. If it uses imperial, match with imperial tools. IRONCUBE offers both metric and imperial options across the jumbo range, including the 1-1/2 inch friction wrench, the 1-7/8 inch model, and the 2-1/4 inch wrench for the largest imperial fasteners.

Choosing the Right Wrench Type for Heavy Equipment Work

Having the right size is step one. Choosing the right wrench type for the specific application is step two, and it matters just as much. There are several styles of 36mm to 46mm wrenches available, each with distinct advantages.

Combination Wrenches

These feature an open end on one side and a box end on the other. The open end slides onto bolts from the side, which is necessary when the fastener can’t be accessed from above. The box end provides a more secure six- or twelve-point grip. Combination wrenches are the most versatile option but require lifting and repositioning after each turn — a significant drawback on large fasteners where each repositioning means handling a heavy, awkward tool.

Ratcheting Wrenches

Ratcheting wrenches solve the repositioning problem. The box end incorporates a ratcheting mechanism that allows continuous turning without removing the wrench from the fastener. For heavy equipment applications, this saves enormous amounts of time and effort, particularly on fasteners that require many turns to install or remove.

The ratcheting mechanism type matters significantly at these sizes. Gear-tooth ratchets work through interlocking metal teeth, which can strip under extreme torque. Friction-type ratchets use friction surfaces instead of gear teeth, providing reliable engagement at any torque level. The entire IRONCUBE friction wrench line uses this friction mechanism across their jumbo sizes, which is a deliberate engineering choice for the torque demands of heavy equipment.

Flex-Head Ratcheting Wrenches

These add an articulating joint between the handle and the head, allowing the head to pivot up to 180 degrees. In heavy equipment, where fasteners often sit between structural members, behind hydraulic lines, or inside tight equipment housings, that flex capability can mean the difference between reaching the bolt and not. For industrial applications of this style, see this guide on heavy-duty flex-head ratchet wrench sets.

Selecting the Right 36mm to 46mm Wrench: Key Considerations

Choosing the appropriate 36mm to 46mm wrenches for your specific needs requires careful consideration of several factors. The wrong choice can lead to inefficient work, damaged equipment, or even personal injury.

Material Quality

The quality of materials used in the wrench’s construction directly impacts its durability and performance. High-carbon steel, chrome vanadium, and similar alloys offer the best combination of strength and resistance to deformation. When evaluating wrenches, look for those with clear material specifications from reputable manufacturers.

Design Features

Ergonomic design becomes increasingly important as wrench size increases. Look for features like comfortable grips, balanced weight distribution, and designs that reduce hand fatigue during extended use. The Heavy Duty Flex Head Ratchet Wrench Set offers innovative design features that make working with large fasteners more manageable.

Precision and Tolerances

The precision with which the wrench jaws are manufactured affects both performance and safety. Poorly fitting wrenches can slip, potentially damaging fasteners or causing injury. Professional-grade wrenches maintain tight tolerances that ensure a secure fit on fasteners.

Warranty and Support

Given the significant investment required for quality large wrenches, consider the manufacturer’s warranty and customer support. Companies like IronCube Works stand behind their products with comprehensive warranties and responsive customer service.

Safety Considerations: Working Smart with Large Wrenches

The substantial forces involved when using 36mm to 46mm wrenches make safety considerations paramount. A slipping wrench or a broken tool can cause serious injury, so following proper safety protocols is essential.

Always ensure the wrench properly fits the fastener before applying force. A loose fit dramatically increases the risk of slippage. When possible, push rather than pull on the wrench—this reduces the risk of injury if the wrench suddenly slips.

For particularly stubborn fasteners, avoid using “cheater bars” or other extensions that weren’t designed for the tool. These can exceed the wrench’s design limits and cause catastrophic failure. Instead, consider using a specialized tool like the Friction Wrench 2 1/4 inch designed for high-torque applications.

Proper body positioning is crucial when working with large wrenches. Maintain a stable stance with your feet shoulder-width apart, and position your body to avoid being in the path of movement if the wrench should slip. Never use a wrench as a hammer, and avoid striking it with other tools unless it’s specifically designed for such use.

For comprehensive safety guidelines, the How to Use Flex Head Ratchet Wrench Set Safely guide provides detailed instructions on proper techniques.

Summary

36mm to 46mm wrenches represent an essential category of tools for anyone working with heavy equipment, agricultural machinery, or industrial applications. Their specialized design, robust construction, and precise sizing make them indispensable for properly maintaining the large fasteners that keep heavy machinery operating safely and efficiently.

When selecting these tools, prioritize quality materials, precise manufacturing, and appropriate design features for your specific applications. Proper maintenance and safety practices will ensure these tools provide reliable service for years to come. As technology continues to advance, we can expect to see continued innovation in this specialized category of tools, with improvements in materials, ergonomics, and specialized features for different industries.

Whether you’re a professional mechanic, equipment operator, or maintenance technician, having the right 36mm to 46mm wrenches in your toolkit is essential for working efficiently and safely with heavy equipment. By understanding the different types available, selecting the appropriate tools for your needs, and following proper maintenance and safety procedures, you’ll be well-equipped to handle the challenges of maintaining and repairing the heavy machinery that keeps our industries moving.

For those looking to expand their collection of these essential tools, the wrenches section at IronCube Works offers a comprehensive selection of quality options designed for professional use.

FAQs

What makes 36mm to 46mm wrenches different from standard wrenches?

The primary difference lies in their size and construction. 36mm to 46mm wrenches are specifically designed for the large fasteners found in heavy equipment, agricultural machinery, and industrial applications. They’re constructed from stronger materials and built to withstand significantly higher torque forces than standard household wrenches. The increased size also requires special consideration for ergonomics and safety, as the forces involved are much greater.

Can I use a 36mm to 46mm wrench with a cheater bar for extra torque?

Using cheater bars or extensions with 36mm to 46mm wrenches is generally not recommended unless the wrench is specifically designed for such use. These extensions can exceed the tool’s design limits, potentially causing catastrophic failure and injury or equipment damage. For high-torque applications, it’s better to use specialized tools like torque multipliers or impact wrenches designed for the specific fastener size you’re working with.

How often should I replace my 36mm-to-46 mm wrenches?

The replacement frequency for 36mm to 46mm wrenches depends on several factors, including usage frequency, the forces applied, and how well they’re maintained. With proper care and normal use, quality wrenches can last many years or even decades. However, they should be immediately replaced if you notice any signs of wear, deformation, or damage, particularly to the jaw surfaces. Regular inspection after each use is the best practice to ensure your wrenches remain safe and effective.

Are expensive 36mm to 46mm wrenches worth the investment?

For professional or frequent heavy equipment work, investing in high-quality 36mm to 46mm wrenches is definitely worth it. Premium wrenches offer better materials, more precise manufacturing, and often superior design features that enhance both performance and safety. They’re also more likely to maintain their accuracy over time and typically come with better warranties. For occasional home use, mid-range options might be sufficient, but for critical applications, the reliability and safety of professional-grade tools are invaluable.

Where can I find reliable information about specific 36mm to 46mm wrench applications?

For detailed information about specific applications of 36mm to 46mm wrenches, several resources are available. The IronCube Works website offers comprehensive product information and application guides. Additionally, manufacturer documentation for specific equipment models typically includes the required wrench sizes for various maintenance tasks. For general knowledge, resources like the Wikipedia article on wrenches provide historical context and technical information about different wrench types and their applications.