Industrial maintenance is unforgiving. A seized bolt on heavy machinery can halt an entire production line, cost thousands per hour, and put technicians under pressure to deliver fast, safe solutions. That is exactly where Jumbo Friction Ratcheting Wrench Sets prove their value. These oversized, high-torque tools are designed for situations where standard spanners simply fail. They grip better, apply power more efficiently, and allow continuous motion without removing the wrench from the nut.

If you work in manufacturing, construction, agriculture, oil and gas, or heavy equipment repair, choosing the right Jumbo Friction Ratcheting Wrench Sets is not just about convenience. It directly impacts productivity, safety, and long-term operating costs. This guide explores the top options available, explains how friction ratcheting technology works, compares features, and links you to trusted resources and product pages so you can make an informed purchase.

What Makes Jumbo Friction Ratcheting Wrench Sets Different

Before diving into specific product recommendations, understanding the technology helps explain why these tools outperform conventional alternatives. The wrench as a fundamental tool has existed for centuries, but modern friction ratcheting designs represent significant engineering advances over traditional fixed or adjustable wrenches.

Friction jaw mechanisms grip fasteners through surface contact rather than a precise dimensional fit. When you close a friction wrench around a nut, serrated or textured jaw surfaces bite into the metal, creating a secure hold that resists slippage under torque. This approach offers tremendous versatility since the same wrench handles multiple fastener sizes within its adjustment range.

The ratcheting component adds efficiency that manual workers immediately appreciate. Traditional wrenches require lifting and repositioning after each partial turn. Ratcheting mechanisms maintain engagement while the handle swings back, allowing continuous motion in confined spaces. For industrial work involving dozens or hundreds of fasteners daily, this time savings compounds dramatically.

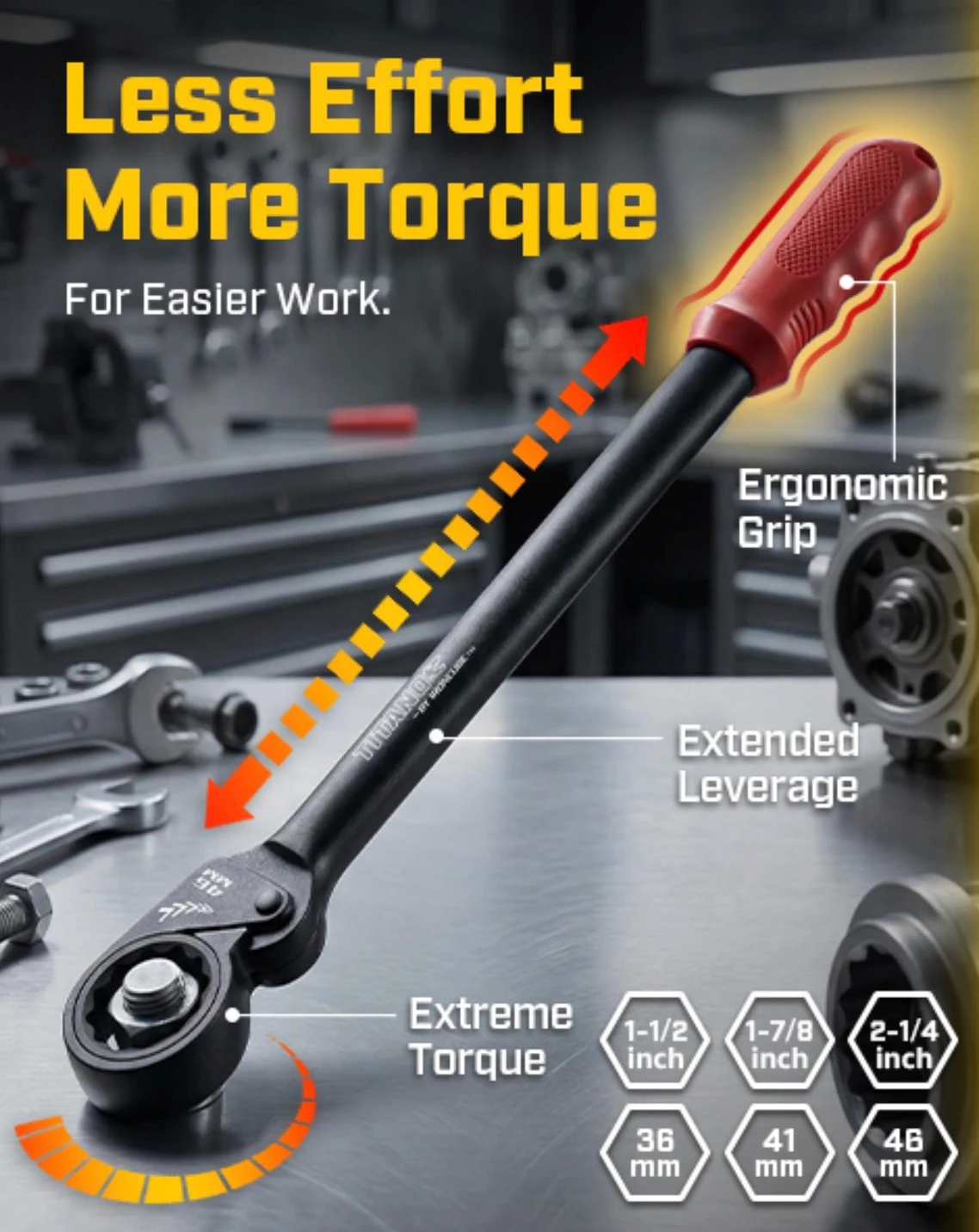

Professional jumbo friction ratcheting wrench sets combine these advantages in tools sized for industrial-scale hardware. While household adjustable wrenches might top out around 1.5 inches, industrial versions reach 2.25 inches or larger. The IRONCUBE Works complete wrench collection demonstrates this range with options spanning common industrial sizes.

Selection Criteria for Industrial Jumbo Friction Ratcheting Wrench Sets

Choosing the right set requires evaluating several factors that impact long-term value and daily performance. Price alone tells an incomplete story. A bargain set that fails within months costs more than quality tools lasting years.

Size Range and Coverage

The first consideration involves matching set contents to your actual fastener inventory. Analyze the equipment you maintain to identify the size ranges appearing most frequently. Pipeline work tends toward larger sizes than general manufacturing maintenance. Agricultural equipment presents different challenges than petrochemical facilities.

Most professional jumbo friction ratcheting wrench sets include between three and six pieces covering overlapping ranges. A well-designed set minimizes gaps while avoiding redundancy. The sweet spot typically spans 36mm through 57mm or approximately 1.5 to 2.25 inches in imperial measurements.

Material Construction and Durability

Steel composition directly affects tool longevity and performance. Chrome vanadium alloy dominates the professional market due to its optimal balance of hardness and toughness. Harder steels resist wear but may crack under impact. Softer alloys absorb shock but deform under heavy loads. Chrome vanadium threads this needle effectively.

Heat treatment processes further differentiate quality levels. Premium manufacturers control tempering precisely to achieve consistent hardness throughout each tool. Inconsistent treatment creates weak points where failures initiate. Reputable brands publish their metallurgical specifications, demonstrating confidence in their processes.

Surface treatments protect against corrosion while affecting grip characteristics. Chrome plating provides the standard baseline, though some manufacturers add proprietary coatings for enhanced protection. Industrial environments expose tools to petroleum products, cleaning chemicals, and moisture that accelerate corrosion on untreated steel.

Ratcheting Mechanism Reliability

The ratchet represents the most mechanically complex component and common failure point. Higher tooth counts enable finer engagement increments, reducing the minimum swing arc in tight spaces. However, extremely fine-tooth designs may wear faster under heavy loads typical of industrial applications.

Direction selection mechanisms vary between manufacturers. Toggle switches, rotating collars, and flip levers each present tradeoffs. Evaluate which design works best with gloved hands in your typical conditions. Learning how to use flex head ratchet wrench sets safely covers techniques applicable to all ratcheting wrench styles.

The Top 5 Jumbo Friction Ratcheting Wrench Sets for 2026

After evaluating dozens of options against professional requirements, these five sets consistently deliver the performance industrial users demand. Each excels in specific areas, making the best choice dependent on your particular priorities and applications.

1. IRONCUBE Professional Industrial Series

The IRONCUBE Works industrial series stands out for comprehensive size coverage combined with exceptional build quality. This collection spans the most commonly needed industrial sizes while maintaining reasonable weight for extended use. Chrome vanadium construction throughout ensures durability under demanding conditions.

Key pieces in this lineup include the 1-1/2 inch heavy-duty ratcheting spanner for mid-range applications and the larger 2-1/4 inch friction wrench for heavy equipment work. The friction jaw design grips worn or damaged fasteners that fixed wrenches cannot engage effectively.

Users particularly praise the smooth ratcheting action and positive direction switching. The mechanism maintains engagement even under maximum load, preventing the dangerous slippage that occurs with lesser tools. For teams seeking reliable jumbo friction ratcheting wrench sets that justify their investment through years of service, this series delivers consistent value.

2. IRONCUBE Metric Precision Collection

Facilities working primarily with metric fasteners appreciate the precision sizing in this collection. Rather than relying solely on adjustable mechanisms, these tools offer specific metric dimensions that ensure optimal engagement geometry. The 41mm jumbo ratchet spanner exemplifies this approach with jaw dimensions matched precisely to common industrial fittings.

The 46mm ratcheting spanner handles larger bolts and industrial fittings with the same precision. This targeted sizing reduces jaw stress compared to wrenches operating at the edge of their adjustment range. Manufacturing facilities maintaining imported equipment often standardize on metric jumbo friction ratcheting wrench sets to match their hardware specifications.

The collection also includes the 36mm torque friction wrench which adds controlled torque application to the friction jaw concept. For applications requiring consistent tightening specifications, this feature prevents over-torquing that damages fittings or under-torquing that allows loosening.

3. IRONCUBE Heavy Equipment Specialist Set

Contractors and maintenance teams working primarily with heavy equipment face unique challenges requiring specialized solutions. The heavy equipment specialist set addresses these demands with extended reach handles and reinforced jaw construction designed for the massive fasteners found on construction machinery, mining equipment, and agricultural implements.

The 1-7/8 inch friction wrench anchors this collection with capacity suited to the oversized hardware common in heavy equipment applications. Combined with complementary sizes, the set covers most scenarios without requiring supplementary tools. For additional context on heavy equipment applications, the guide on big ratchet wrenches for heavy equipment provides detailed application information.

Field service technicians particularly value the portable organization system included with this set. A quality carrying case protects tools during transport while keeping them organized for quick access. When minutes matter during equipment breakdowns, knowing exactly where each wrench sits speeds repairs significantly.

4. IRONCUBE Flex Head Industrial Series

Angled access requirements distinguish flex head designs from straight versions. When obstructions prevent a direct approach to fasteners, articulating heads reach where rigid tools cannot. The heavy-duty flex head ratchet wrench set for industrial use brings this capability to jumbo sizes rarely available in flex configurations.

The flex mechanism adds complexity but dramatically expands application possibilities. Pipeline valve stations, confined machinery compartments, and structural installations all present scenarios where flex heads prove invaluable. Understanding how flex head ratchet wrench sets save time on repairs illustrates efficiency gains that apply across industrial contexts.

These jumbo friction ratcheting wrench sets command premium pricing due to their specialized design, but users consistently report productivity improvements that justify the investment. For facilities where access constraints frequently slow maintenance work, flex head capabilities eliminate frustrating workarounds.

5. IRONCUBE Agricultural and Rural Applications Set

Agricultural equipment presents distinct requirements from factory or urban industrial applications. Remote locations, variable conditions, and equipment diversity demand versatile tool sets. The jumbo ratcheting wrench set for agriculture addresses these needs with comprehensive coverage and rugged construction suitable for demanding rural environments.

Farm equipment spans decades of manufacturing standards, mixing metric and imperial hardware across different brands and eras. This set provides both measurement systems in sizes matching common agricultural applications. The corrosion-resistant finish handles exposure to fertilizers, fuel, and weather that quickly destroy lesser tools.

Harvest season breakdowns cannot wait for specialty tool orders. Having appropriate jumbo friction ratcheting wrench sets on hand enables immediate response to equipment failures. The comprehensive nature of this collection ensures farmers and rural mechanics maintain readiness for diverse repair scenarios throughout the agricultural calendar.

Top Jumbo Friction Ratcheting Wrench Sets

The following table summarizes key characteristics of each recommended set to facilitate comparison based on your specific requirements.

| Set Name | Size Range | Best For | Key Feature | Value Rating |

| Professional Industrial | 1-1/2″ to 2-1/4″ | General industrial | Versatility | Excellent |

| Metric Precision | 36mm to 46mm | Metric facilities | Precise sizing | Very Good |

| Heavy Equipment | 1-7/8″ to 2-1/4″ | Construction/mining | Extended reach | Very Good |

| Flex Head Industrial | Multiple sizes | Confined spaces | Articulating head | Premium |

| Agricultural | Mixed metric/imperial | Farm equipment | Dual standards | Excellent |

Purchasing Considerations for Jumbo Friction Ratcheting Wrench Sets

Budget Planning and Total Cost of Ownership

The initial purchase price represents only part of the total investment equation. Quality tools serving reliably for years deliver better value than cheap alternatives requiring frequent replacement. Consider the hidden costs of tool failure including equipment damage, project delays, and injury risk.

Professional jumbo friction ratcheting wrench sets typically range from moderate to premium pricing depending on specifications and brand reputation. The IRONCUBE lineup offers options across this spectrum, allowing buyers to match investment to their operational requirements and budget constraints.

Bulk purchasing often provides significant savings for organizations equipping multiple teams or locations. The guide on finding quality wholesale jumbo wrench sets outlines strategies for maximizing procurement value while maintaining quality standards.

Vendor Selection and Support

Beyond the tools themselves, vendor relationships affect long-term satisfaction. Responsive customer service, warranty support, and technical guidance distinguish premium suppliers from commodity dealers. Establishing relationships with knowledgeable vendors provides ongoing value through application advice and problem-solving assistance.

The IRONCUBE Amazon storefront offers convenient purchasing with reliable fulfillment for individual tool needs. For larger orders or specialized requirements, direct contact with the IRONCUBE team ensures personalized attention to specific needs.

How These Sets Compare in Real-World Use

Choosing among Jumbo Friction Ratcheting Wrench Sets becomes easier when you consider practical factors rather than just size.

Smaller jumbo sizes such as 36mm and 41mm are ideal for daily industrial maintenance. They offer the best balance of control and strength. Larger sizes like 1-7/8 inch and 2-1/4 inch excel in extreme applications where torque demands are high. Sets that focus on a specific size range often deliver better performance than generic oversized kits.

If you are comparing these tools against other ratcheting options, you may find value in reading the detailed breakdowns already published on Iron Cube Works. Articles such as the guide on big ratchet wrenches for heavy equipment, the analysis of jumbo wrench sets for agriculture, and the in-depth look at heavy-duty flex head ratchet wrench sets provide strong supporting context.

Why Industrial Buyers Trust Iron Cube Works

Reputation matters in industrial procurement. Buyers want consistency, transparency, and reliable performance. Iron Cube Works positions itself as a specialist rather than a generic retailer, and that focus shows in its content and product lineup.

Their educational resources, including articles on selecting the best ratchet wrench sets and on how flex head designs save time in auto repairs, demonstrate a commitment to long-term customer success rather than short-term sales.

If you are evaluating Jumbo Friction Ratcheting Wrench Sets for your team, it is worth exploring their broader ecosystem and even reaching out directly through the contact page for tailored recommendations.