Introduction

Wrenches. They’re not just tools; they’re the unsung heroes of every garage, workshop, and construction site. From the skyscrapers that touch the clouds to the cars that zoom past you on the highway, wrenches have played a part. But did you know there are two primary types of wrenches that rule the roost? Enter: Standard and Metric wrenches.

Mindmap – Standard vs Metric Wrenches

Definition of a Wrench and its Primary Functions

A wrench isn’t just a piece of metal. It’s a device designed to provide grip and mechanical advantage in applying torque to turn objects—typically rotary fasteners, like nuts and bolts. Think of it as the handshake of the tool world; firm, reliable, and essential.

The Global Prevalence of Wrenches in Various Industries

From automotive to aerospace, plumbing to production lines, wrenches are everywhere. They’re like the universal language of the tool world. And just like any language, they have dialects. In the wrench world, these dialects are known as Standard and Metric. Curious about the backstory of these two? Let’s dive into some history.

Historical Context

History isn’t just about kings and wars; it’s also about tools. And when it comes to wrenches, the tale is as riveting as the bolts they turn.

Origins of the Standard (SAE) System in the US

The Standard system, often referred to as the SAE (Society of Automotive Engineers) system, is as American as apple pie. Born in the US, this system was the brainchild of engineers who wanted a standardized way of measuring tools and fasteners. It’s like the imperial system, but for tools.

The Global Adoption and Origins of the Metric System

While the US was busy with its Standard system, the rest of the world was getting cozy with the Metric system. Originating in France during the French Revolution, this system was all about simplicity and universality. It’s the reason why your soda comes in liters and your running track is 400 meters. And when it comes to wrenches, the Metric system has its own set of rules and sizes.

Historical Events Leading to the Development of Both Systems

The tale of two systems isn’t just about measurements; it’s about geopolitics, trade, and innovation. The US, with its vast manufacturing base, needed a system that catered to its unique needs. Hence, the Standard system. Meanwhile, post-revolutionary France wanted to break away from the old and usher in the new. Enter the Metric system. But how do these two differ when it comes to wrenches? Let’s get down to the nitty-gritty.

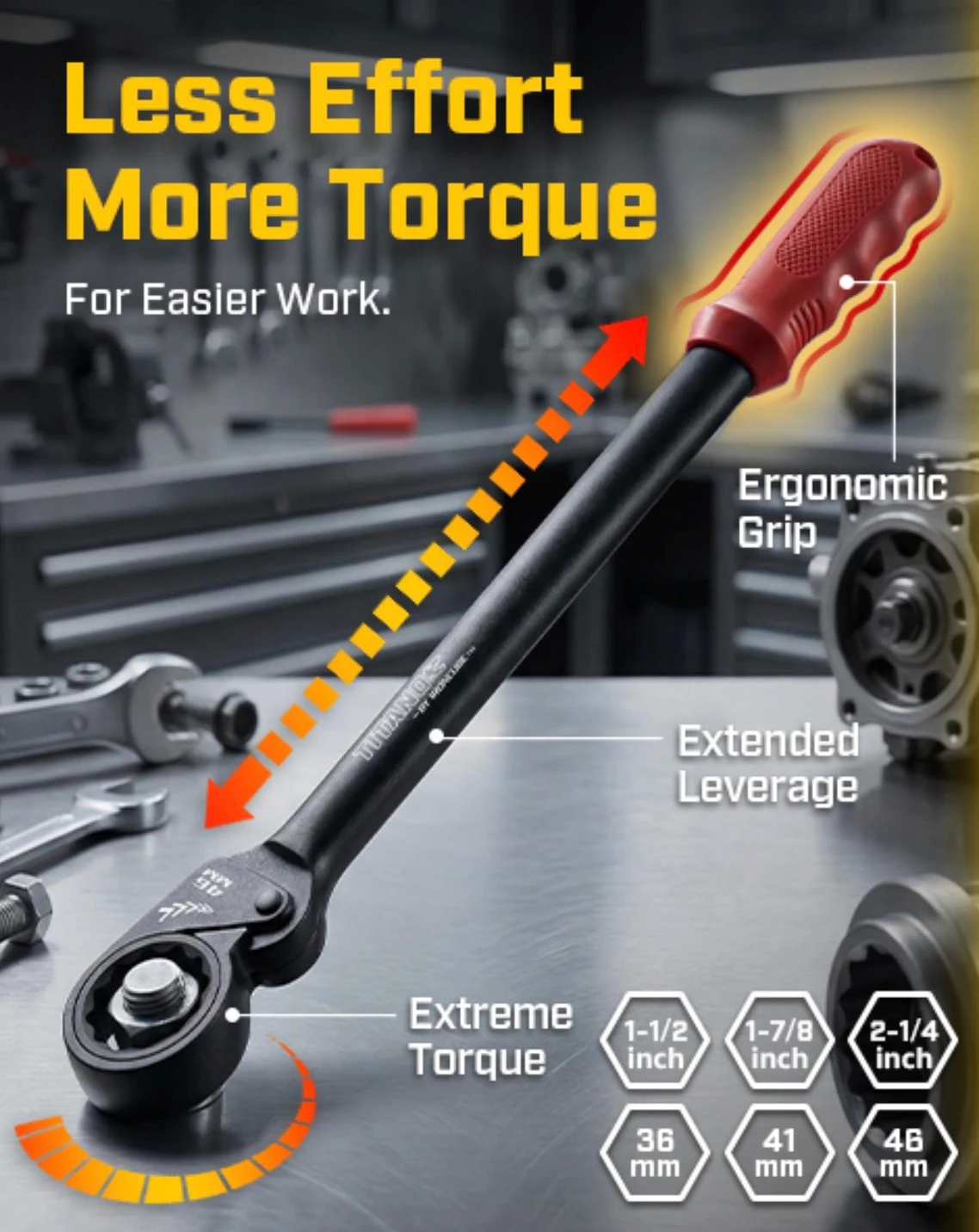

Check out our wide-jaw adjustable wrench, a perfect blend of precision and power.

Key Differences Between Standard and Metric Wrenches

Ever tried fitting a square peg in a round hole? That’s what it feels like when you mix up Standard and Metric wrenches. Let’s break down the differences.

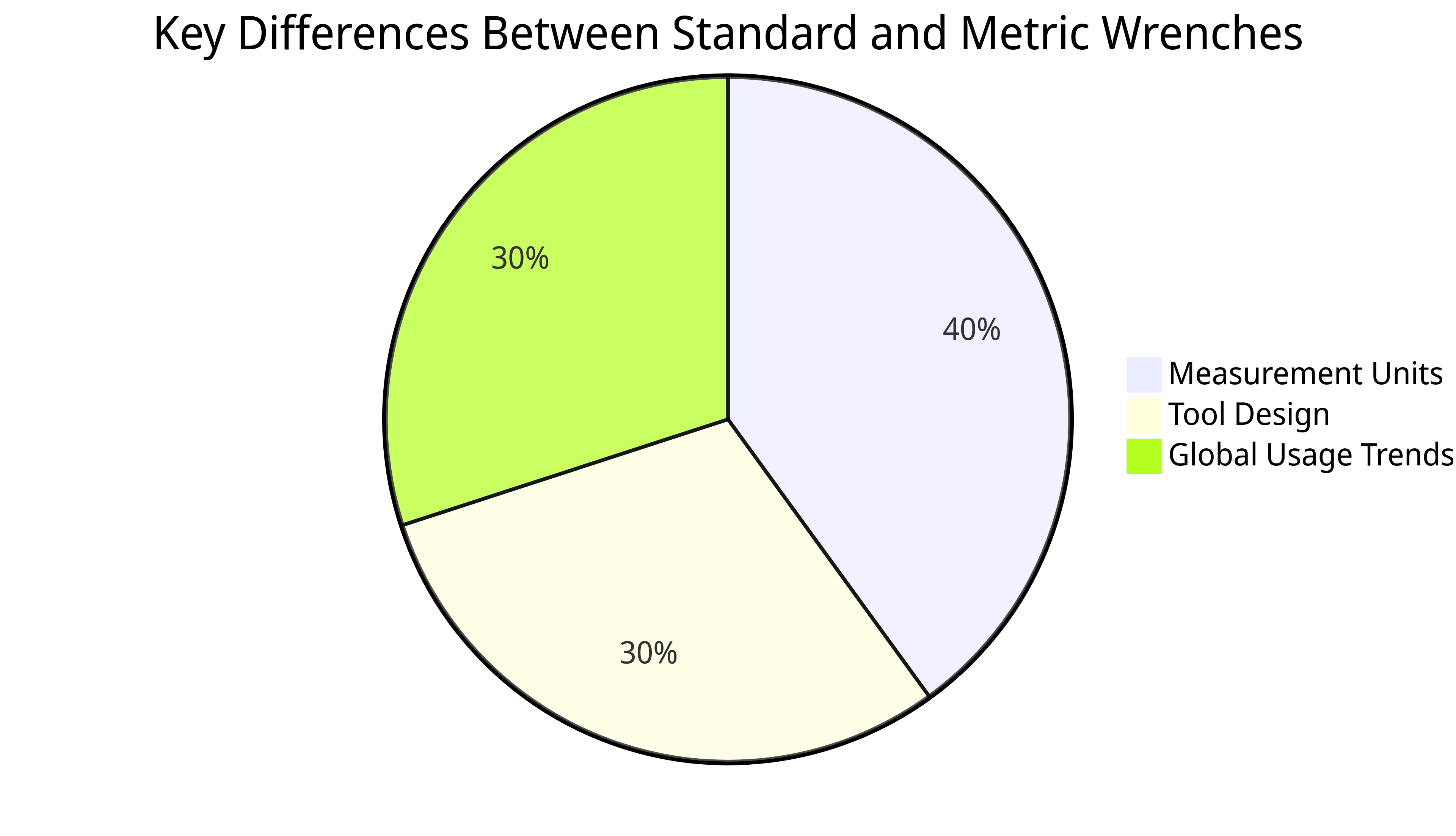

Pie Chart – Key Differences Between Standard and Metric Wrenches

Measurement Units: Fractions (for Standard) vs. Millimeters (for Metric)

Standard wrenches love fractions. 1/2″, 3/4″, 1/8″ – these are their jam. They’re like the pie slices of the tool world. On the flip side, Metric wrenches are all about millimeters. 10mm, 15mm, 20mm – clean, crisp, and to the point.

Visual Differences in Tool Design

At first glance, both wrenches might look like long-lost twins. But look closer. Standard wrenches often have a bulkier design, while Metric ones are sleeker. It’s like comparing a linebacker to a sprinter.

Regional Preferences and Global Usage Trends

Here’s a fun fact: If you’re in the US, chances are you’ve mostly dealt with Standard wrenches. But hop on a plane to Europe or Asia, and Metric wrenches rule the roost. It’s not just about geography; it’s about history, trade, and industry standards.

Conversion Challenges and the Need for Dual Toolsets

Ever tried converting inches to millimeters on the fly? It’s a headache. That’s why many professionals swear by dual toolsets. One for Standard, one for Metric. Because in the world of wrenches, size does matter.

For those who love versatility, our crescent socket set is a game-changer.

Of course! Let’s continue our deep dive into the world of wrenches.

Metric Wrenches

Metric wrenches, the sleek rulers of the tool world, have their own unique charm and precision. Let’s explore them in detail.

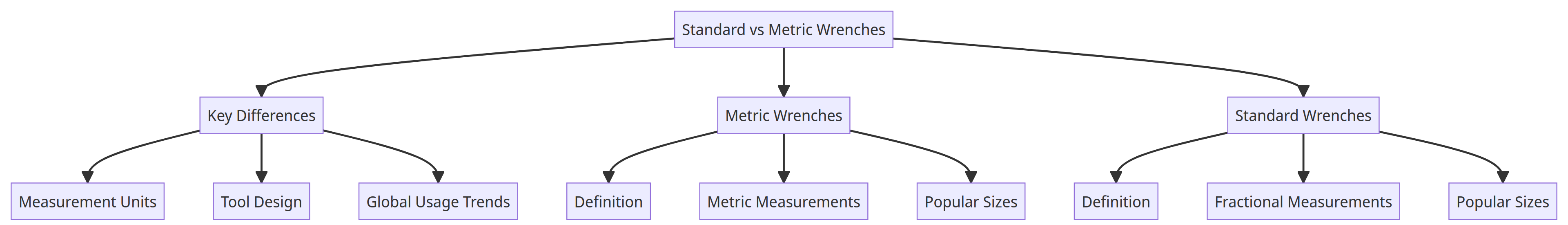

Flow Chart – Understanding the Differences Between Wrenches

Detailed Definition and Characteristics

Metric wrenches are based on the metric system, which means they’re measured in millimeters (mm). Simple, right? These wrenches are often marked with numbers like 10, 12, 14, representing their size in millimeters. They offer precision, especially when working with machinery and vehicles manufactured outside the US.

The Science Behind Metric Measurements

The metric system is all about base-10. It’s straightforward, logical, and easy to understand. When you move from one size to the next in metric wrenches, you’re usually jumping by a set number of millimeters. This uniformity makes it easier to find the right tool for the job.

Popular Sizes and Their Applications

- 8mm & 10mm: These are the darlings of the automotive world. Perfect for tight spaces and commonly used sizes in vehicles.

- 12mm & 14mm: Ideal for larger bolts, often found in household appliances and some automotive tasks.

- 17mm & 19mm: These are your heavy hitters, great for bigger machinery and high-torque applications.

Industries and Regions Where Metric Wrenches Dominate

While metric wrenches are popular worldwide, they’re especially prevalent in Europe, Asia, and parts of Africa. Industries like automotive manufacturing, aerospace, and electronics, especially those with international ties, often prefer metric measurements for their universality.

For those who need precision and variety, our angle wrench set is a must-have.

Standard (SAE) Wrenches

Ah, the Standard wrenches, or as they’re often known, SAE wrenches. They’re the old-school rockstars of the tool world, especially in the US.

Detailed Definition and Characteristics

Standard wrenches, based on the imperial system, are measured in fractions of an inch. You’ll often see sizes like 1/2″, 5/8″, or 3/4″. These wrenches are a testament to the American engineering legacy, offering robustness and reliability.

The Rationale Behind Fractional Measurements

The fractional system might seem complex, but it has its roots in practicality. By dividing inches into fractions, engineers could achieve a wide range of sizes without resorting to decimals. It’s a system that’s been tried, tested, and trusted for decades.

Popular Sizes and Their Applications

- 1/4″ & 3/8″: These sizes are perfect for small to medium tasks, from fixing household items to automotive maintenance.

- 1/2″ & 5/8″: Ideal for more substantial tasks, these sizes are commonly used in construction and heavy machinery.

- 3/4″ & 7/8″: When you’re dealing with large bolts and high-torque situations, these are your go-to sizes.

Industries and Regions Where Standard Wrenches are Prevalent

The US is the heartland of Standard wrenches. From automotive to construction, these wrenches are the preferred choice. However, they also find favor in parts of Canada and a few other regions that have historical ties to the American industrial system.

Looking for a reliable set? Our wrench tool set offers the best of both worlds.

Conversion Between Metric and Standard

In an ideal world, one wrench would fit all. But in reality, sometimes you need to dance between the Metric and Standard systems. Let’s talk conversions.

Importance and Usage of Conversion Charts

A conversion chart is like a translator for your wrenches. It helps you match a Standard size to its Metric counterpart and vice versa. These charts are lifesavers, especially when you’re working on diverse projects or dealing with imported machinery.

Practical Examples Showcasing Conversions

- 1/2″ (Standard) is roughly equivalent to 13mm (Metric).

- 5/8″ (Standard) is close to 16mm (Metric).

- 3/4″ (Standard) can be matched with 19mm (Metric).

Tools and Software Available for Quick Conversions

In today’s digital age, there’s an app for everything, including wrench conversions. Several mobile apps and online tools can instantly convert Standard to Metric measurements and vice versa. These digital aids ensure you always have the right size at your fingertips.

Mistakes to Avoid When Converting

- Rounding Off Too Much: Precision is key. Always use accurate conversion values.

- Assuming Close is Good Enough: Even a millimeter can make a difference. Ensure the fit is snug.

- Over-Tightening: If you’re using a slightly mismatched wrench, avoid over-tightening, as it can strip the bolt.

For those who love a challenge, our proto ratcheting wrench set is a game-changer.

Practical Applications

Wrenches aren’t just tools; they’re solutions to real-world problems. Whether you’re fixing a leaky faucet or assembling a rocket (yes, they use wrenches too!), understanding when to use which wrench is crucial.

Scenarios Where Metric Wrenches are Preferable

- Imported Vehicles: Got a European or Asian car? Metric wrenches will be your best friends.

- Electronics: Many modern gadgets and appliances use metric screws and bolts.

- International Projects: If you’re collaborating with teams from outside the US, chances are they’re using the metric system.

Scenarios Favoring Standard Wrenches

- American Cars: Classic or modern, many US-made vehicles predominantly use standard measurements.

- US Construction Sites: Building or renovating? Standard wrenches are often the go-to in American construction.

- Vintage Machinery: Older machines, especially those made in the US, typically use standard bolts.

Maintenance and Care Tips for Both Types

- Regular Cleaning: Keep your wrenches free from dirt and grease. A simple wipe-down post-use can extend their lifespan.

- Proper Storage: Use a wrench tool set box or pouch to prevent misplacement and damage.

- Avoid Over-Torquing: Applying too much force can damage both the tool and the bolt. Always use the right size for the job.

- Rust Prevention: Store in a dry place and occasionally apply a light coat of oil to prevent rusting.

Recommendations for Building a Versatile Toolset

- Start with the Basics: A mix of commonly used metric and standard sizes is a good starting point.

- Invest in Quality: A well-made wrench can last a lifetime. Consider brands known for durability and precision.

- Stay Updated: As industries evolve, so do tool requirements. Keep an eye out for emerging trends and new tool innovations.

For a versatile addition, consider our T-handle torx set.

People Also Ask

Ah, the burning questions! Let’s address some common curiosities about wrenches.

Historical Reasons for the Existence of Two Systems

The divergence stems from historical, industrial, and geopolitical reasons. While the US developed its own system based on its industrial needs, the metric system emerged in Europe, aiming for universality and simplicity.

Quick Identification Tips for Metric vs. Standard Wrenches

- Markings: Metric wrenches are usually marked in whole numbers (like 10, 12, 14mm), while Standard ones use fractions (like 1/2″, 3/4″).

- Feel & Design: Often, metric wrenches are sleeker, while their standard counterparts might feel a tad bulkier.

The Debate Over Hybrid Tool Sets

Hybrid tool sets, which combine both metric and standard sizes, are gaining popularity. They offer versatility, especially for those who work on diverse projects. However, purists might prefer dedicated sets for precision.

Future Predictions: Will One System Eventually Prevail?

The debate rages on! While the metric system is globally dominant, the standard system’s deep roots in American industries make it hard to phase out. The future might see more hybrid approaches, but both systems are here to stay for the foreseeable future.

Curious about the future of wrenches? Discover where gear wrenches are made.

Semantically Related Searches

Beyond wrenches, the metric vs. standard debate extends to various tools and industries. Let’s explore some related topics.

The Broader Metric vs. Standard Debate Beyond Wrenches

From screws to drill bits, the tug-of-war between metric and standard measurements is omnipresent. Each system has its champions and its applications.

The Role of Digital Tools in Modern Measurements

Digital calipers, apps, and software have made it easier than ever to switch between systems, ensuring precision and reducing manual errors.

Global Trends and Shifts in Tool Preferences

While Asia and Europe lean heavily towards metric, the US remains a stronghold for standard tools. However, globalization is blurring these lines, with many professionals now adept in both systems.

The Environmental and Economic Impacts of Tool Production

Sustainability is the buzzword. Modern tool manufacturers, like IRONCUBE WORKS, are focusing on eco-friendly production methods, ensuring durability while minimizing environmental impact.

Are ratcheting wrenches worth the investment? Find out now!

Conclusion

In the grand tapestry of tools, wrenches hold a place of honor. Whether you’re team metric or team standard, understanding the nuances of each system is crucial. As the world grows more interconnected, the lines between these systems might blur, but their importance remains undiminished.